An elastic self-tensioning stainless steel cable tie

A self-tensioning, stainless steel technology, applied in the direction of flexible and elongated components, transportation and packaging, packaging, etc., can solve the problems of inconvenience, inability to meet, cumbersome locking operation, etc., to improve storage quality, reduce wear, and tighten moderate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make it easy to understand the technical means, creation features, achieved goals and effects of the present invention, the present invention will be further described below with reference to the specific embodiments.

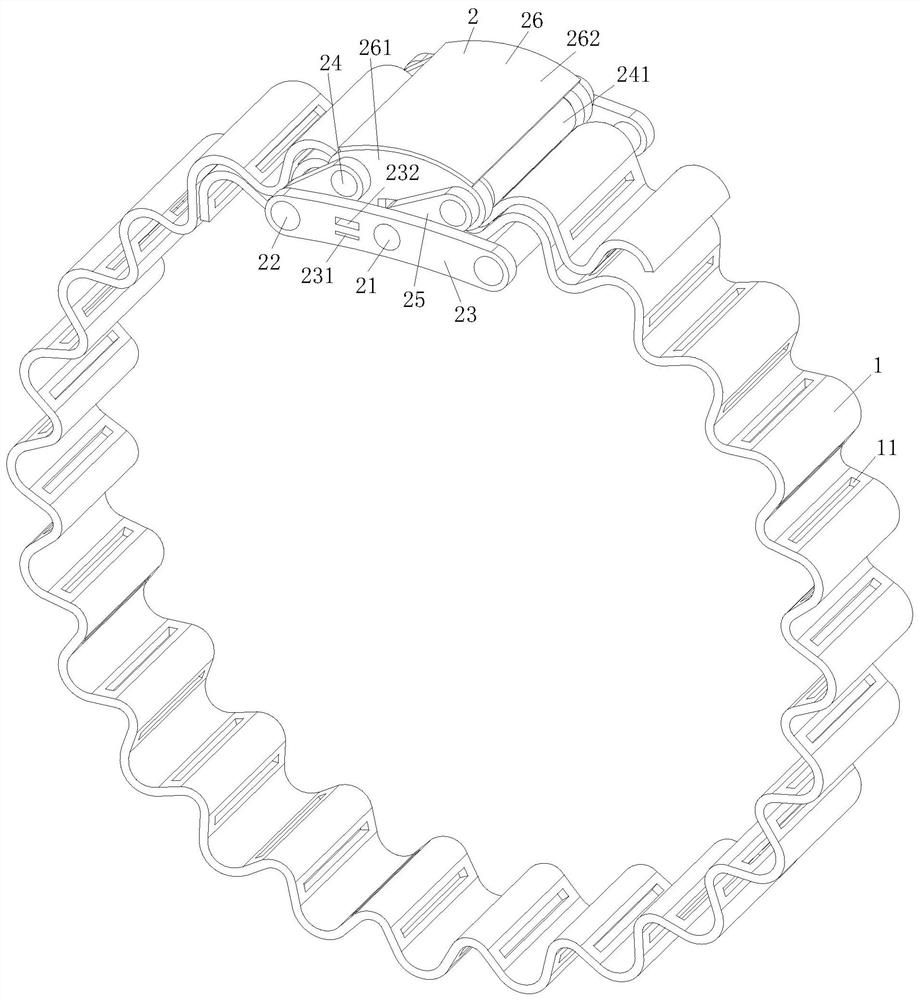

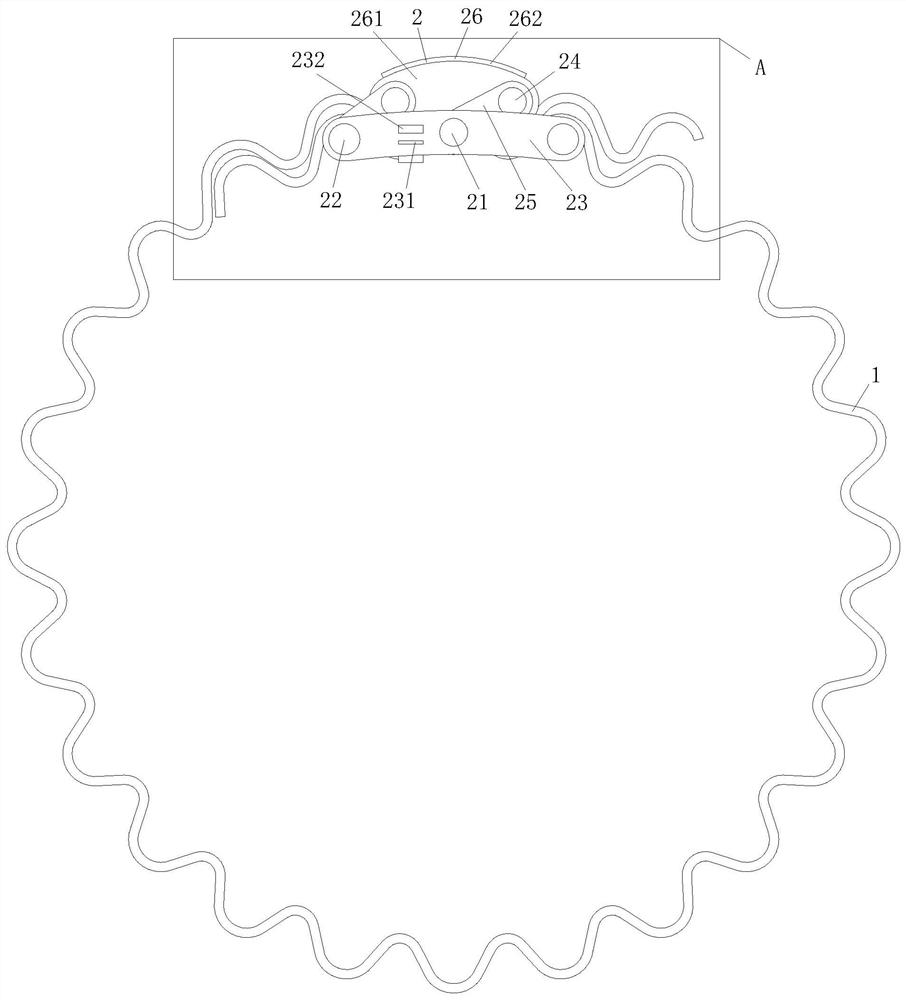

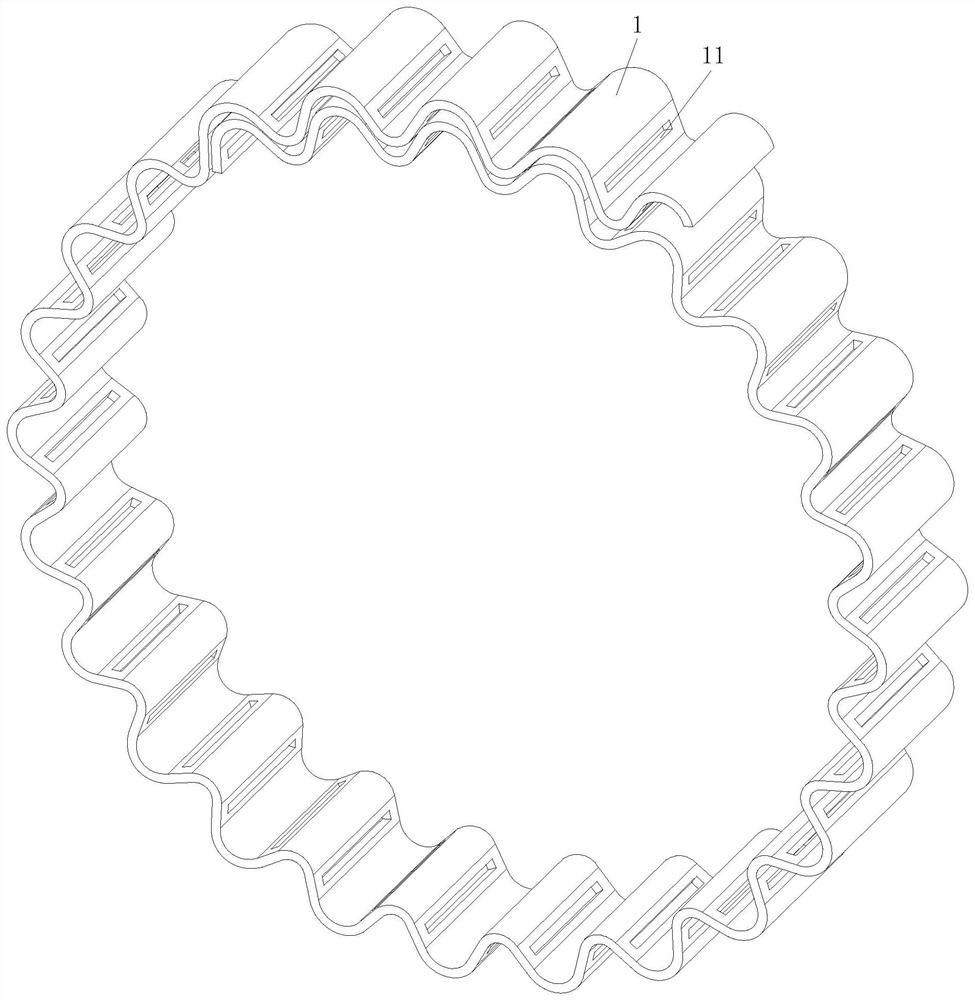

[0034] like Figure 1 to Figure 3 As shown, an elastic self-tensioning stainless steel cable tie includes a tightening strap 1 and a locking member 2; the tightening strap 1 is corrugated along the length direction; the tightening strap 1 has the ability to bend and deform; The locking member 2 is provided at the position where the two ends of the strap 1 meet and overlap; the locking member 2 is used to lock the two ends of the strap 1 that are overlapped with each other.

[0035] When working, wrap the tie belt 1 around the object to be fastened for one week, and place the two ends of the tie belt 1 overlaid, and then press the corrugated tie belt 1 together through the locking member 2, and then use the The corrugated structure of the tie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com