Method for detecting steel bar diameter in concrete member

A technology for concrete and steel bars, which is applied in the field of detecting the diameter of steel bars in concrete members, and can solve problems such as affecting the bearing capacity of members and damage to the cross-section of members.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In view of this, the core of the present invention is to disclose a method for detecting the diameter of steel bars in concrete members, which can reduce the damage to the bearing capacity of members while obtaining the diameter of steel bars.

[0026] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

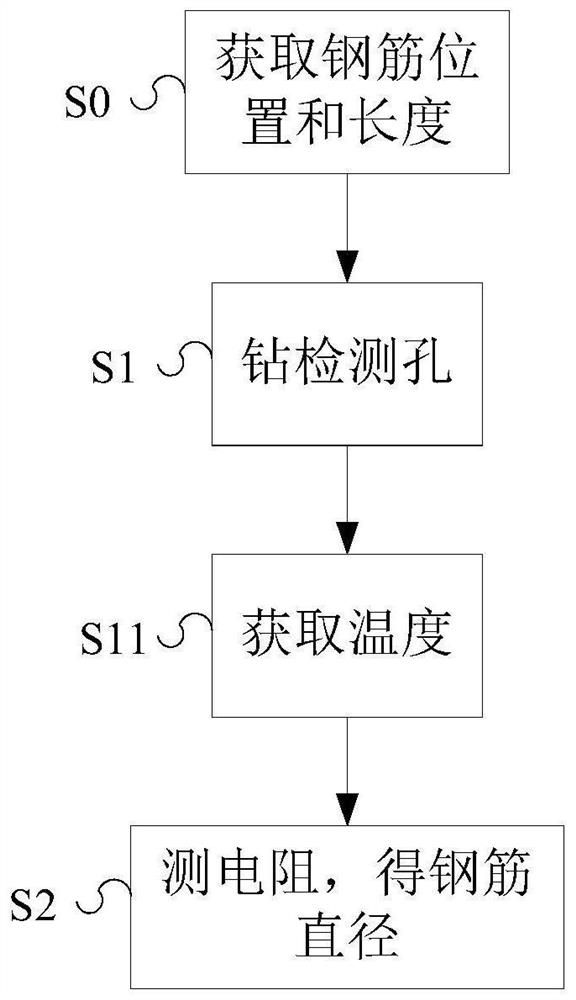

[0027] Such as figure 1 As shown, the invention discloses a method for detecting the diameter of steel bars in concrete members, which comprises the following steps:

[0028] Step S1: Drill inspection holes.

[0029] Drill the inspection hole along the axial direction of the steel bar of the concrete component to be tested, and ensure that the depth of the inspection hole reaches the surface of the steel bar. Specifically, use a percussion drill to drill the hole. After the drilling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com