A kind of in-situ cross-linked bio-based jelly for fracturing or profile control and its preparation method and application

An in-situ cross-linking and bio-based technology, applied in chemical instruments and methods, earth drilling, drilling compositions, etc., can solve problems such as stratum environmental damage, reduce environmental hazards, reduce costs, and simple fermentation methods easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

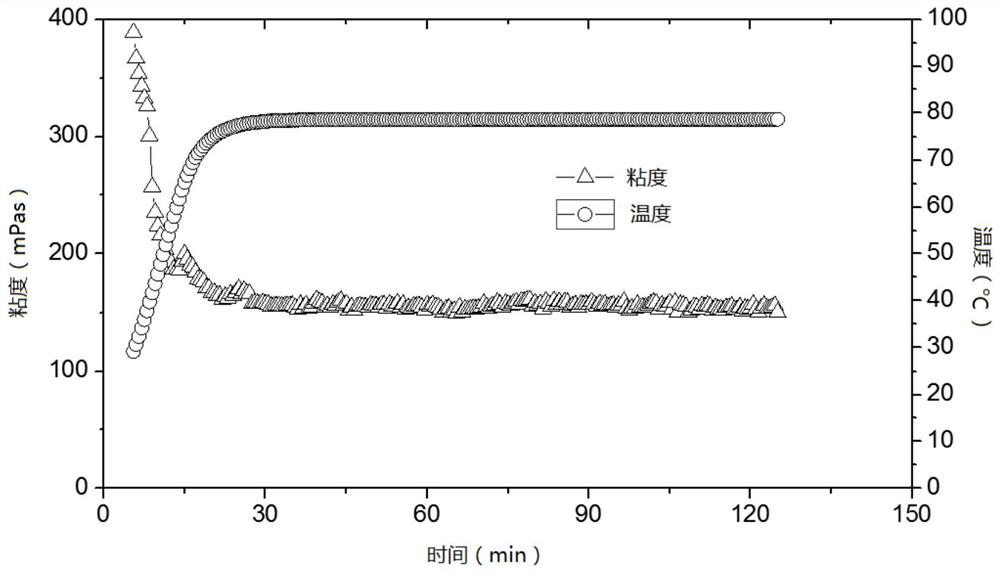

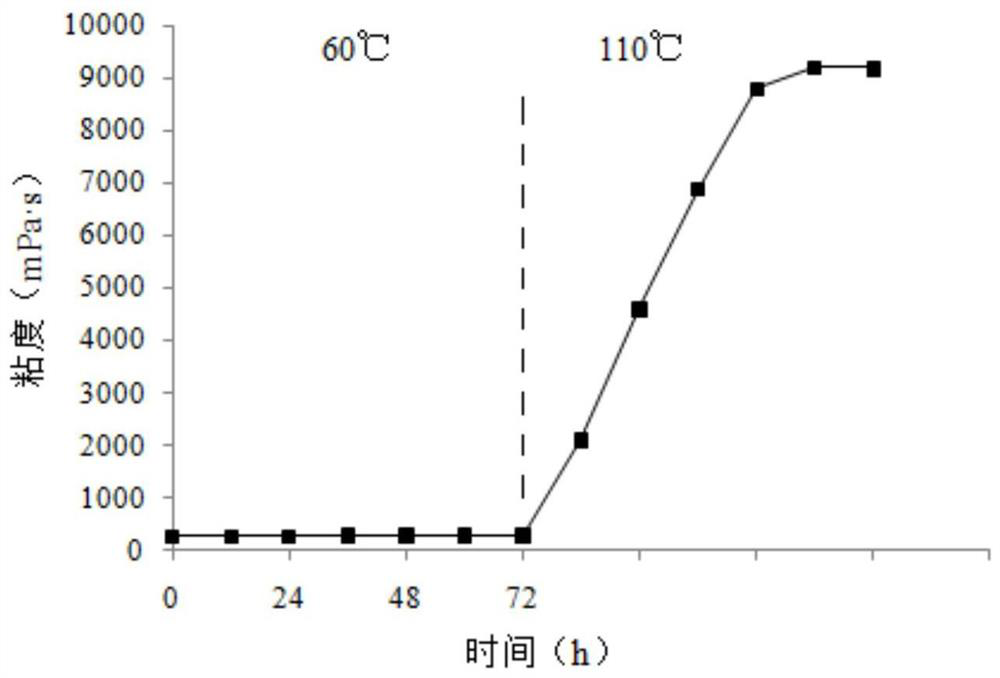

Embodiment 1

[0030] The sphingomonas single bacterium colony that produces guar gum preserved on the plate is inoculated in the seed culture medium (glucose 10g / L, NH 4 NO 3 0.5g / L, KH 2 PO 4 0.5g / L, MgSO 4 0.5g / L, yeast powder 2g / L, peptone 5g / L, pH 7.0~8.0), shake culture at 35°C and 150rpm for 1d to become seed liquid, and the seed liquid was added to the fermentation medium according to the volume ratio of 1:50 ( Glucose 10g / L, sucrose 1g / L, yeast powder 0.5g / L, urea 1g / L, K 2 HPO 4 0.5g / L, MgSO 4 0.2g / L, pH 7.0-8.0), shake culture at 35°C and 150rpm for 3 days to obtain a fermentation broth, and use a rotational viscometer to measure the viscosity of the fermentation broth to be 5060mPa·s. The above-mentioned fermented liquid was diluted 5 times, the viscosity was 246mPa·s, and the concentration of guar gum in the fermented liquid was 2.1g / L, which was used as the biopolymer base liquid for preparing the bio-based jelly.

Embodiment 2

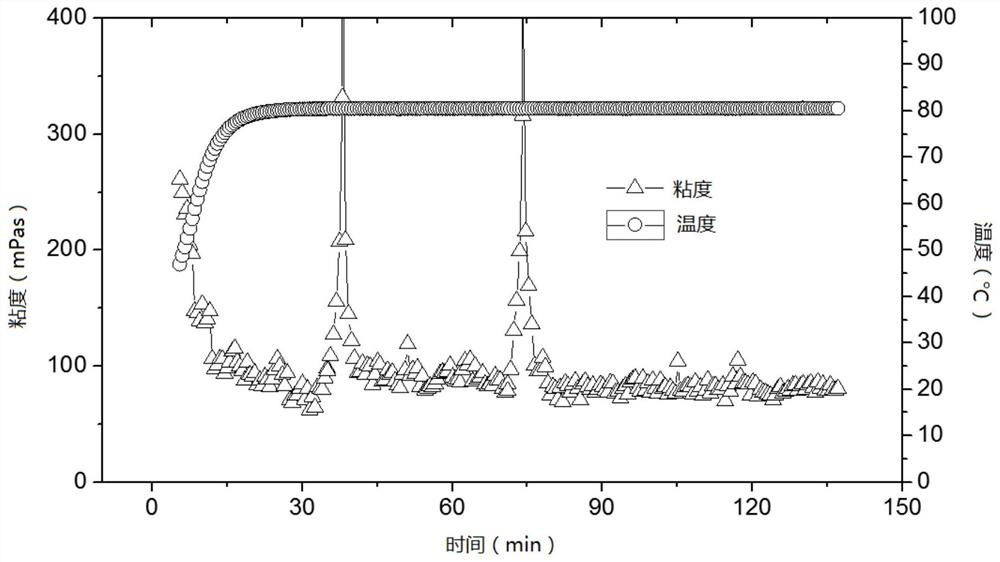

[0032] The Alcaligenes single bacterium colony of producing Velan gum preserved on the plate is inoculated in the seed culture medium (glucose 10g / L, NH 4 NO 3 0.5g / L, KH 2 PO 4 1g / L, MgSO 4 0.5g / L, yeast powder 2g / L, peptone 10g / L, pH 7.0-8.0), shake culture at 35°C and 120rpm for 1d to become seed liquid, and the seed liquid was added to the fermentation medium according to the volume ratio of 1:50 ( Glucose 12g / L, sucrose 2g / L, yeast powder 1g / L, urea 2g / L, K 2 HPO 4 1g / L, MgSO 4 0.1g / L, pH 7.0-8.0), and vibrated at 35°C and 150rpm for 3 days to obtain a fermentation broth. The viscosity of the fermentation broth was measured to be 5230mPa·s using a rotational viscometer. The above fermentation broth was diluted 5 times, the viscosity was 269mPa·s, and the Welan gum concentration in the fermentation broth was 2.7g / L, which was used as the biopolymer base liquid for preparing bio-based jelly.

Embodiment 3

[0034] The Xanthomonas campestris single bacterium colony of producing xanthan gum preserved on the plate is inoculated in the seed culture medium (glucose 15g / L, NH 4 NO 3 1g / L, KH 2 PO 4 0.5g / L, MgSO 4 0.2g / L, yeast powder 5g / L, peptone 5g / L, pH 7.0~8.0), shake culture at 37°C and 180rpm for 2 days to become seed liquid, and the seed liquid was added to the fermentation medium at a volume ratio of 1:20 ( Glucose 15g / L, sucrose 1g / L, yeast powder 0.5g / L, urea 1.5g / L, K 2 HPO 4 0.5g / L, MgSO 4 0.2g / L, pH7.0~8.0. ), vibrated at 37° C. and 150 rpm for 5 days to obtain a fermentation broth, and the viscosity of the fermentation broth was measured to be 5150 mPa·s using a rotational viscometer. The above fermentation broth was diluted 5 times, the concentration of xanthan gum in the fermentation broth was 2.3g / L, and the viscosity was 253mPa·s, which was used as the biopolymer base liquid for preparing bio-based jelly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com