Formula and production process of crystal sugar bird's nest

A production process and bird's nest technology, applied in the field of rock sugar bird's nest formulation and production process, can solve problems such as poor taste, loss of nutrients in bird's nest, impact on cleanliness of bird's nest, etc., to increase taste and aroma, speed up the cooking process, and reduce nutrition. The effect of churn rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

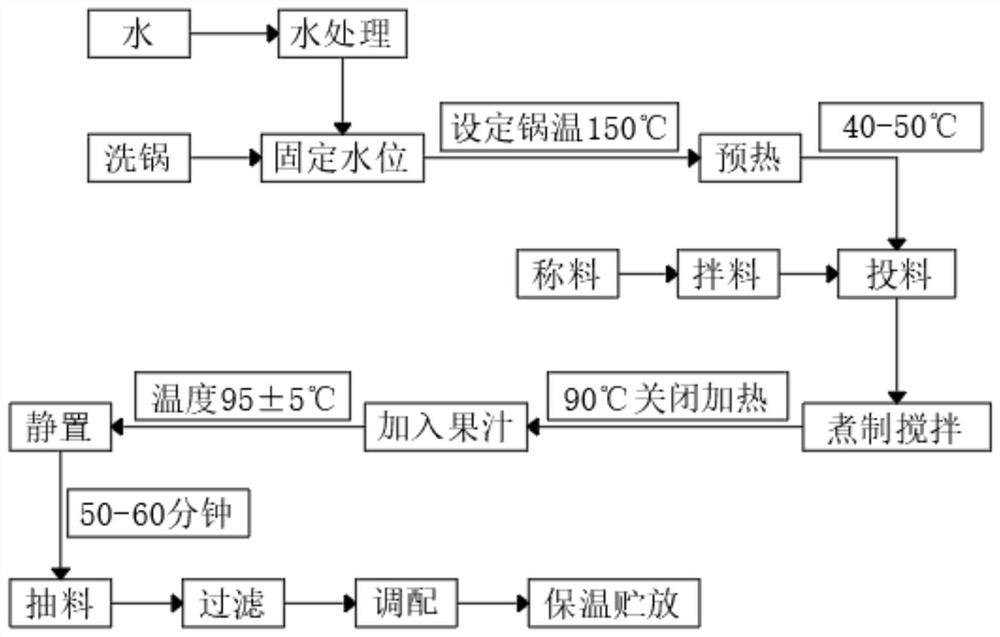

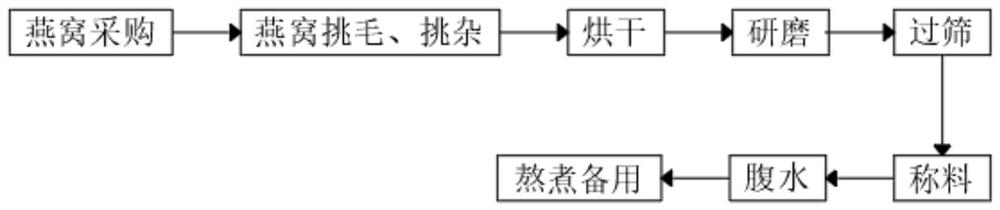

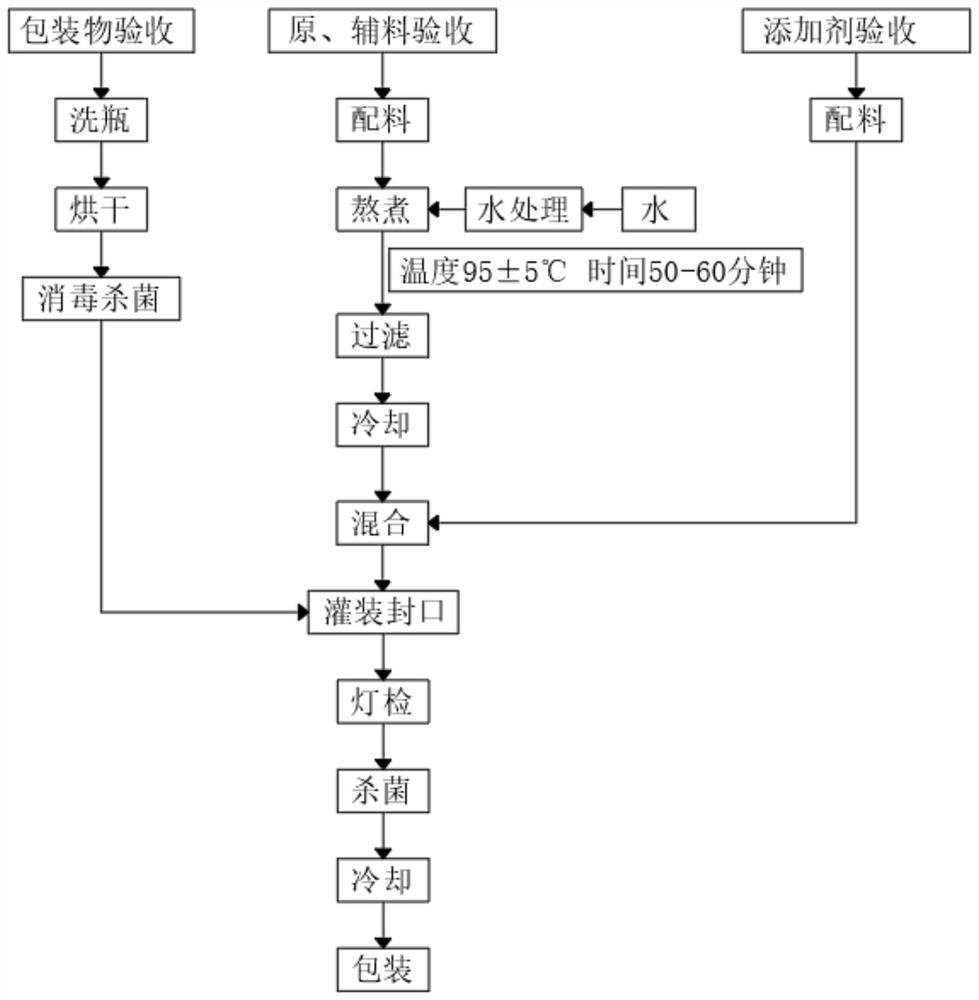

[0029] A kind of production technology of rock sugar bird's nest, comprises the following steps:

[0030] Step a, wash the pot, pour the prepared pure water into the pot after sterilizing and filtering, set the temperature of the pot to 150°C, and quickly preheat the pure water in the pot;

[0031] Step b. When the temperature of the purified water reaches 40-50°C, mix the prepared rock sugar, white sugar, bird’s nest, collagen peptide, acerola cherries, roses, and resistant dextrin into the pot, and cook During the process, the raw materials in the pot are stirred;

[0032] Step c. After the temperature of the mixed material in the pot reaches 80°C, stop heating, then pour fruit juice into the pot, and then let it stand for 50-60 minutes;

[0033] Step d, extracting the materials in the pot in step c, and then filtering and blending to finally prepare the rock sugar bird's nest, and then store the prepared rock sugar bird's nest in an insulated manner.

[0034] The bird's n...

Embodiment 2

[0039] A kind of production technology of rock sugar bird's nest, comprises the following steps:

[0040] Step a, wash the pot, pour the prepared pure water into the pot after sterilizing and filtering, set the temperature of the pot to 150°C, and quickly preheat the pure water in the pot;

[0041] Step b. When the temperature of the purified water reaches 40-50°C, mix the prepared rock sugar, white sugar, bird’s nest, collagen peptide, acerola cherries, roses, and resistant dextrin into the pot, and cook During the process, the raw materials in the pot are stirred;

[0042] Step c. After the temperature of the mixed material in the pot reaches 90°C, stop heating, then pour fruit juice into the pot, and then let it stand for 50-60 minutes;

[0043] Step d, extracting the materials in the pot in step c, and then filtering and blending to finally prepare the rock sugar bird's nest, and then store the prepared rock sugar bird's nest in an insulated manner.

[0044] The bird's n...

Embodiment 3

[0049] A kind of production technology of rock sugar bird's nest, comprises the following steps:

[0050] Step a, wash the pot, pour the prepared pure water into the pot after sterilizing and filtering, set the temperature of the pot to 150°C, and quickly preheat the pure water in the pot;

[0051] Step b. When the temperature of the purified water reaches 40-50°C, mix the prepared rock sugar, white sugar, bird’s nest, collagen peptide, acerola cherries, roses, and resistant dextrin into the pot, and cook During the process, the raw materials in the pot are stirred;

[0052] Step c. After the temperature of the mixed material in the pot reaches 100°C, stop heating, then pour fruit juice into the pot, and then let it stand for 50-60 minutes;

[0053] Step d, extracting the materials in the pot in step c, and then filtering and blending to finally prepare the rock sugar bird's nest, and then store the prepared rock sugar bird's nest in an insulated manner.

[0054] The bird's ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com