Central air intake diversion structure and central air intake vacuum cyclone cleaner

A technology of placement and airflow, which is applied in the field of mid-mounted air intake guide structure, to achieve the effects of reducing volume and weight, reducing motor load, and reducing airflow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

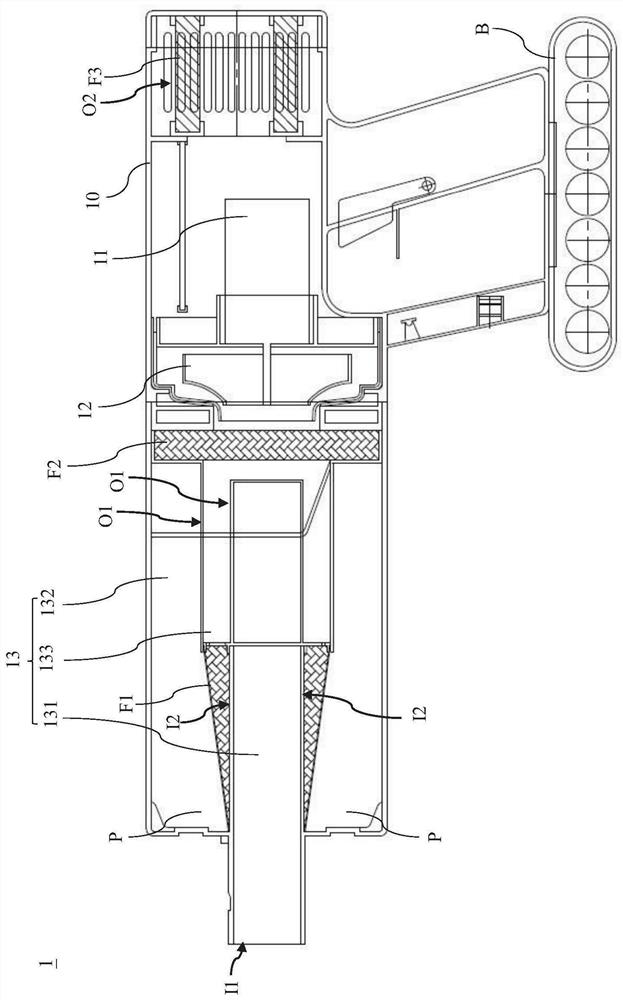

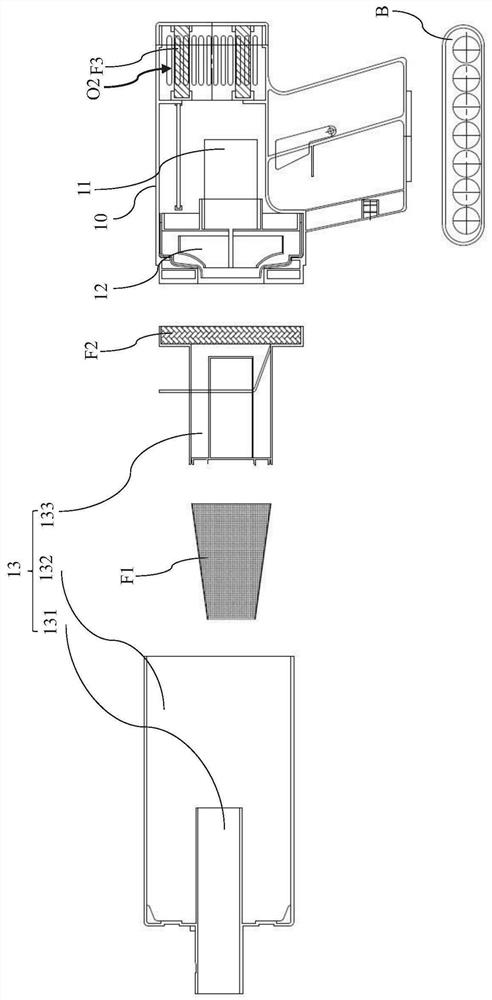

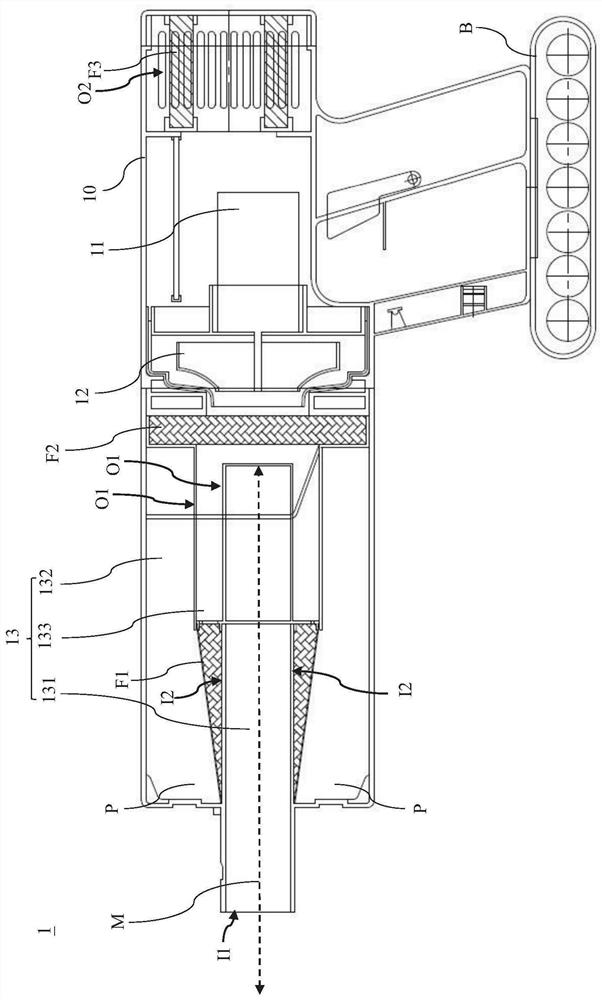

[0028] The following will refer to the relevant drawings to illustrate the embodiment of the mid-mounted air intake guide structure and the mid-mounted intake vacuum cyclone cleaner including the guide structure according to the present invention. For the sake of clarity and convenience in the description of the drawings, Each component may be presented exaggerated or reduced in size and proportion. In the following description and / or claims, when it is mentioned that an element is "connected" or "coupled" to another element, it may be directly connected or coupled to the other element or there may be an intervening element; When "directly connected" or "directly coupled" to another element, there are no intervening elements present, and other words used to describe the relationship between elements or layers should be interpreted in the same manner. For ease of understanding, the same components in the following embodiments are described with the same symbols.

[0029] see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com