Differential device capable of conveniently adjusting material width and cutting layer depth

A differential device and material technology, which is applied in feeding devices, automatic control devices, large fixed members, etc., can solve the problems of high cost of die cutting and high processing requirements of die cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

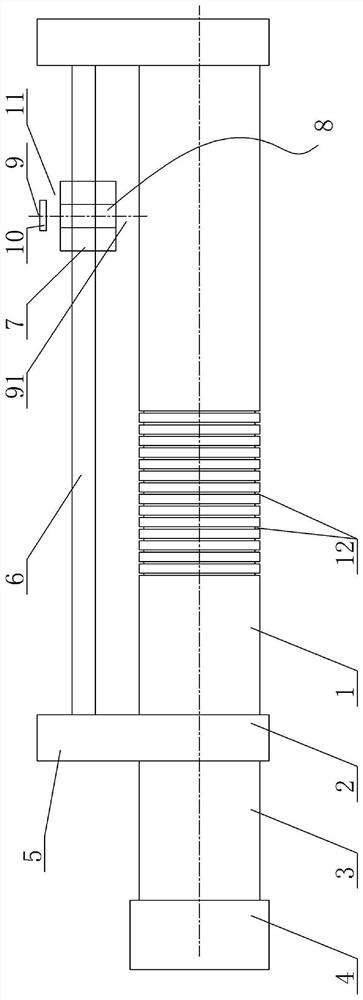

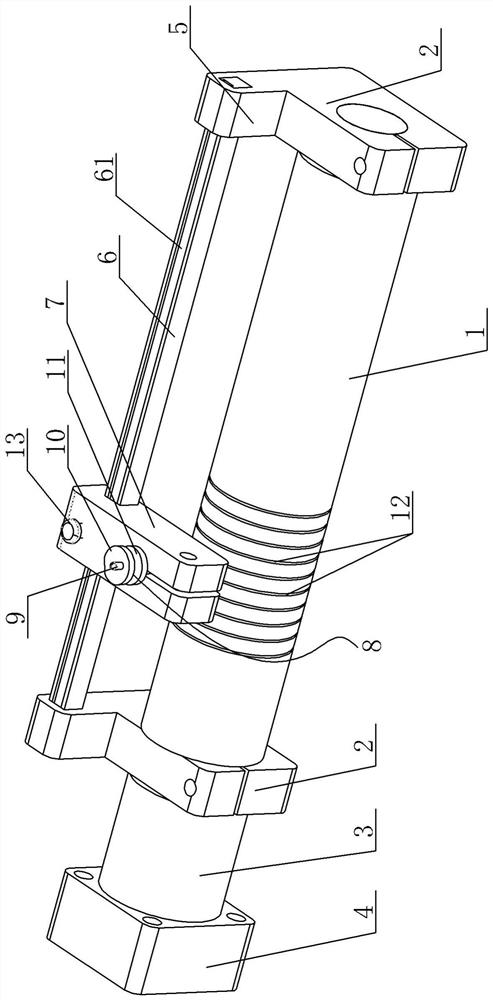

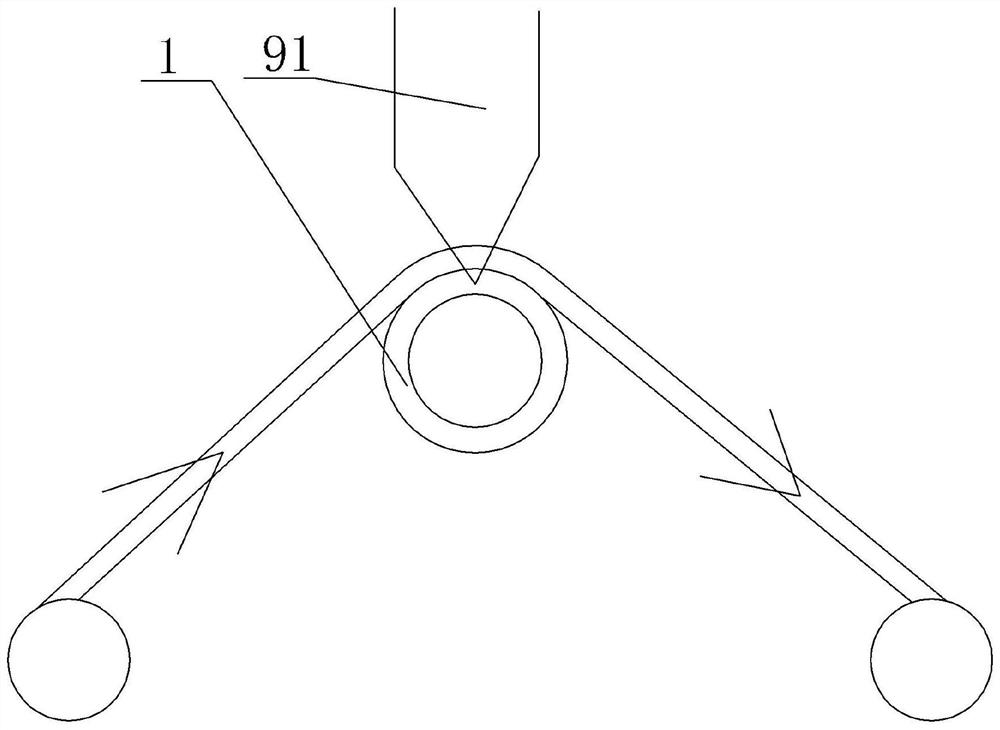

[0018] A differential device for convenient adjustment of material width and depth of cut, see Figure 1-Figure 4 : It includes a bottom shaft 1, the two ends of the length direction of the bottom shaft 1 are respectively inserted into the positioning holes of the corresponding mounting seat plate 2, the bottom shaft 1 is rotated relative to the mounting seat plate 2, and the outer side of the mounting seat plate 2 at one end is fixed A connection seat 3 is provided, the outer end of the connection seat 3 is provided with a connection positioning block 4, the connection positioning block 4 is used to be fixed on the machine, the top of the installation seat plate 2 protrudes to form a support frame 5, and the two sides of the transverse connecting rod 6 The end is inserted in the corresponding positioning hole of the support frame 5 at both ends, the transverse connecting rod 6 is provided with a cutter head fixing bracket 7, and the cutter head fixing bracket 7 is inserted wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com