Tool box

A toolbox and metal ring technology, applied in the field of toolboxes, can solve the problems that the pull rod cannot be disassembled and the wheel strength requirements are increased, and achieve the effects of strengthening the strength, increasing the service life, and strengthening the firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention is described in detail below. The embodiment of the present invention is only for illustrating a specific structure, and the scale of the structure is not limited by the embodiment.

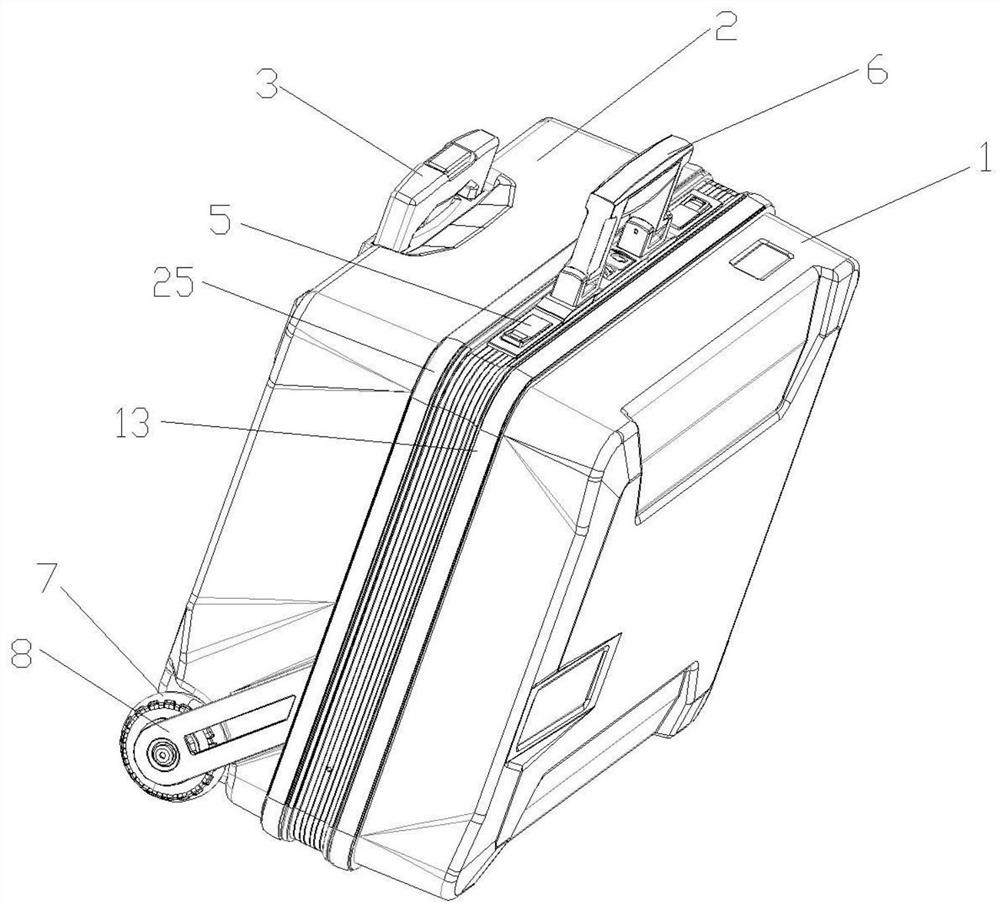

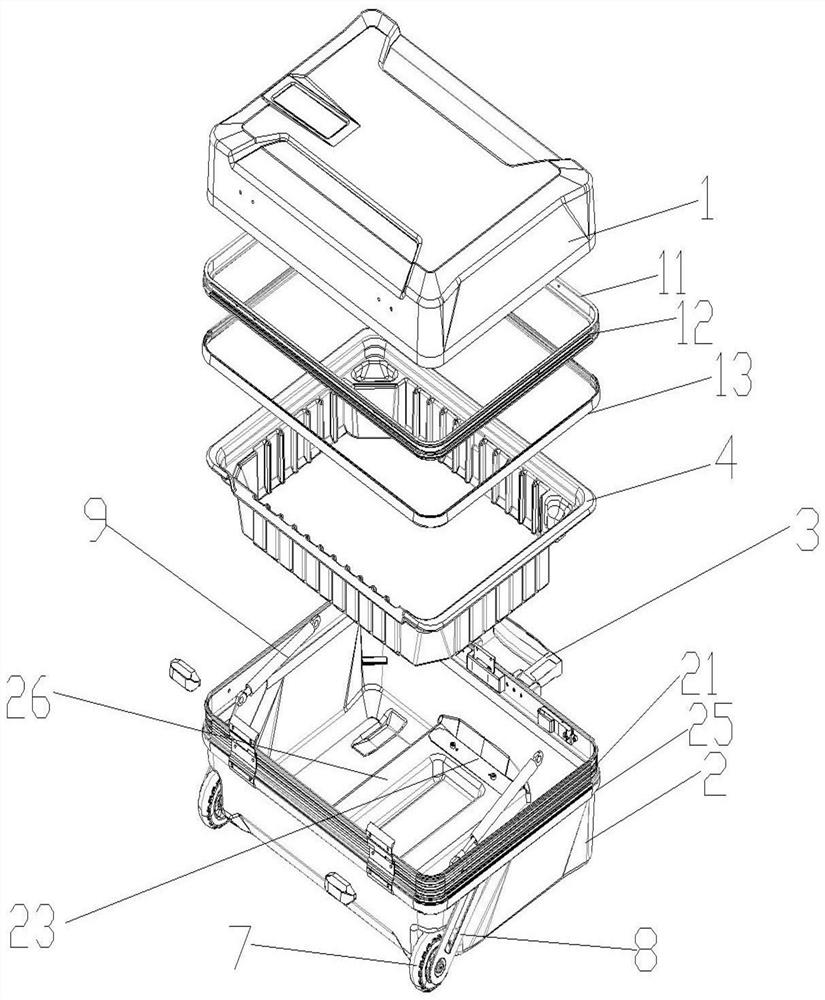

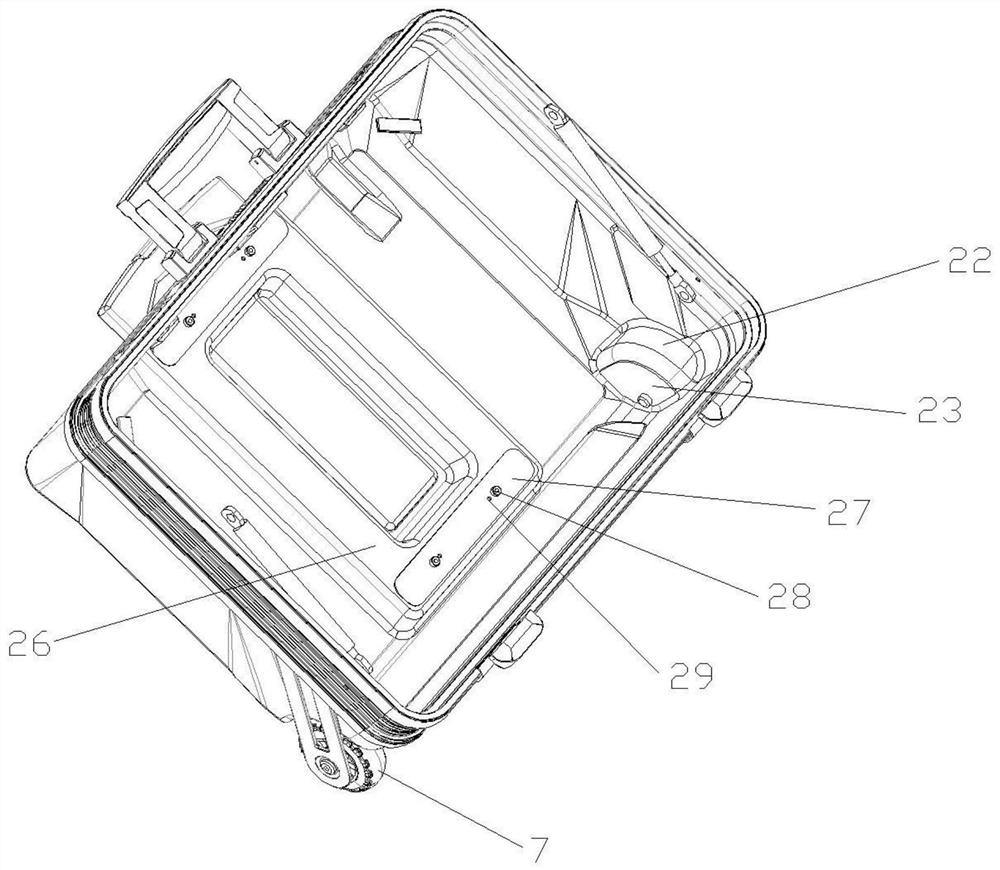

[0027] Such as Figure 1 to Figure 6 The shown toolbox includes a front cover 1, a rear cover 2 and a pull rod 3, the pull rod 3 is fixed on the outside of the rear cover 2, the rear cover 2 and the front cover 1 cooperate to form a box, and the edge of the rear cover 2 is fixed with a first Metal ring 21; lock 5 and handle 6 are fixed on the first metal ring 21; second metal ring 11 is fixed on the edge of front cover 1; first metal ring 21 is provided with first groove 24, nail or screw passes through the second metal ring 21; A groove 24 fixes the first metal ring 21 and the back cover 2, and the first sealing strip 25 is installed in the first groove 24; the second metal ring 11 is provided with a second groove 12, and nails or screws pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com