Movable material uniformizing device and belt conveyor

A mobile, screed technology, used in conveyors, transportation and packaging, loading/unloading, etc., to solve problems such as grooves, uneven roller wear, and tape scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The core of the present invention is to provide a mobile leveler and belt conveyor, which effectively ensures that the transported materials are always kept smooth and uniform.

[0032] In order to enable those skilled in the art to better understand the technical solutions provided by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

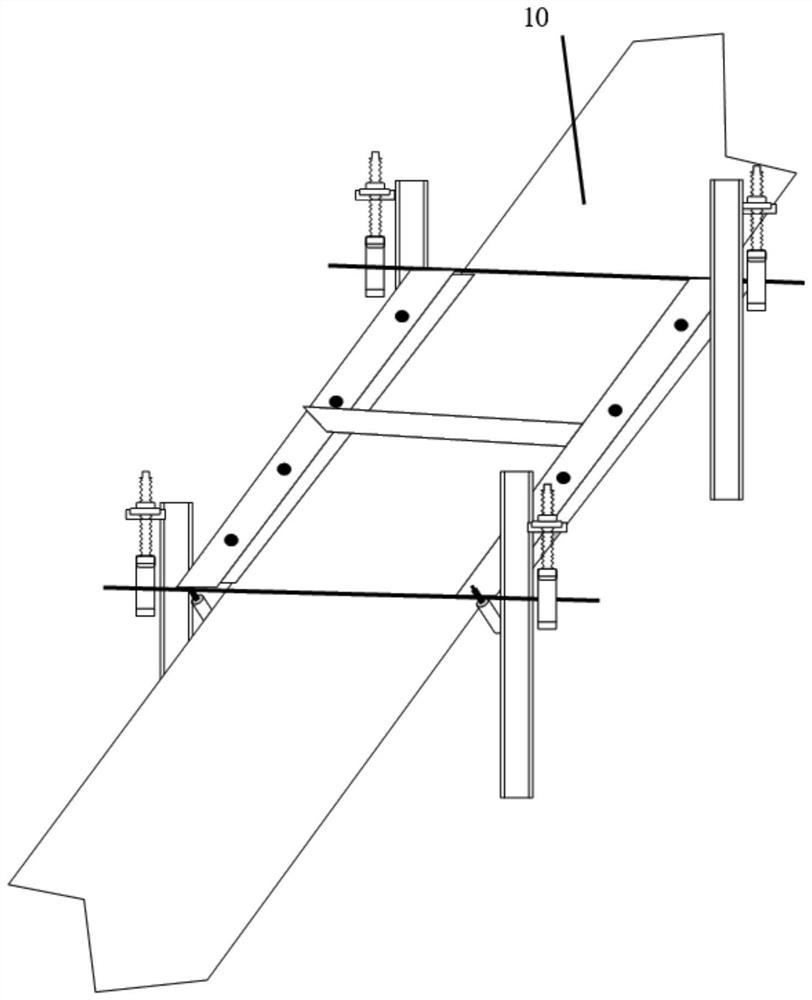

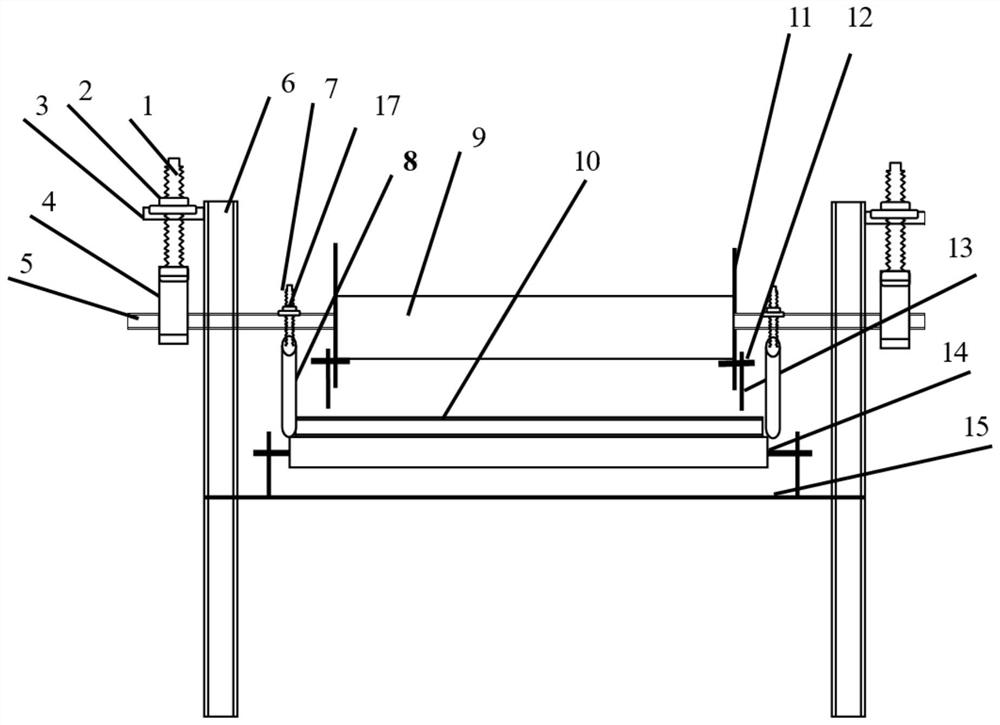

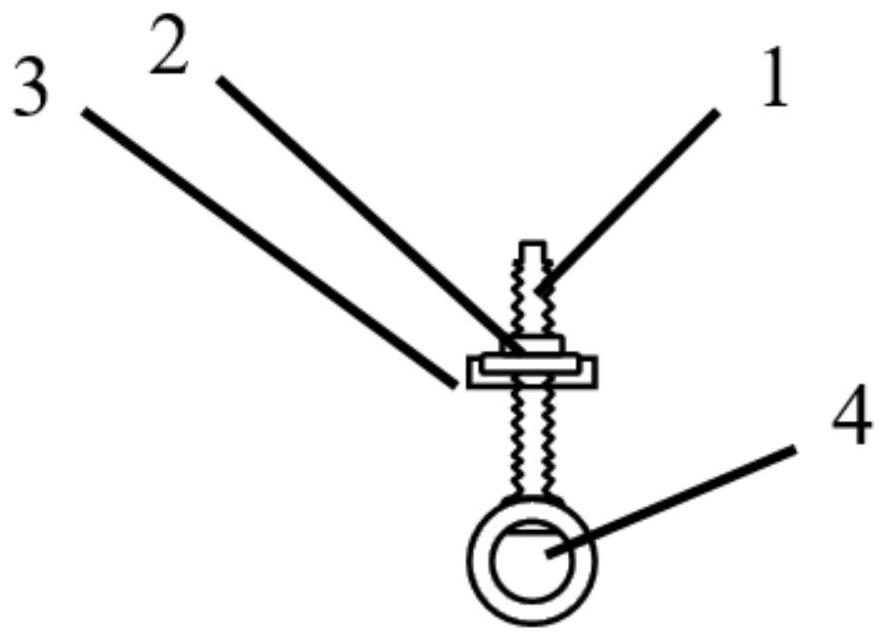

[0033] Please refer to Figure 1-Figure 5 , the present invention provides a mobile leveler, comprising a fixed frame 6, a sliding shaft 5, a leveling plate 9 and side stop wheels 8, wherein the fixed frame 6 mainly plays a supporting role and is symmetrically arranged on both sides of the adhesive tape 10. Sliding shaft 5 is along the width direction of adhesive tape 10, and movably connects fixed frame 6 on both sides, and the width direction of belt conveyor is figure 2 Middle left direction. The even material plate 9 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com