Five-roller coating device

A five-roll coating and coating wheel technology, which is applied to the device for coating liquid on the surface, coating and other directions, can solve the problems of limiting the application range of the coating head, troublesome operation and adjustment, and difficult to clean the coating head.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

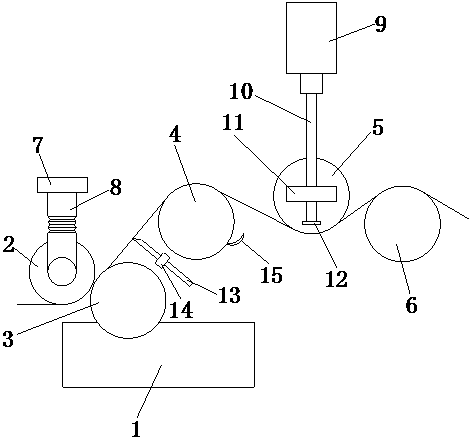

[0022] Such as Figure 1-2 As shown, a kind of five-roller coating device of the present invention includes liquid tank 1, pre-pressing wheel 2, coating wheel 3, rubber equalizing wheel 4, stabilizing wheel 5 and guide wheel 6,

[0023] One end of the coating wheel 3 is arranged in the liquid tank 1, the pre-pressing wheel 2 is arranged on the front end of the coating wheel 3, and the pre-pressing wheel 2 is fixedly arranged on the support seat 7 through an elastic connecting rod 8;

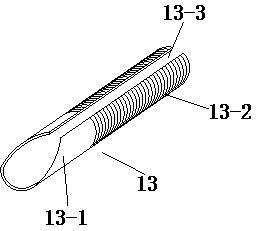

[0024] Described rubber equalizing wheel 4 is arranged on the upper right corner of coating wheel 3, is provided with constant thickness device between rubber equalizing wheel 4 and coating wheel 3; Both the wheel 4 and the second scraper 15 are arranged directly above the liquid tank 1;

[0025] Both sides of described stable wheel 5 are provided with nut 11, and nut 11 is threadedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com