Intersecting twist fabric and production method thereof

A production method and fabric technology, applied in the direction of fabrics, textiles, textiles and papermaking, etc., can solve the problems of consistent performance and single cloth surface effect, and achieve the effects of improving water absorption, good local air permeability, and facilitating popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The yarns used in the cross-twisted fabric include strong twisted yarns, normal twisted yarns and weakly twisted yarns, that is, yarns with the same fineness but different twists.

[0023] The twist range of the yarn used in cross-twisted fabrics is 1-1.5:1:0.5-1.

[0024] The cross-twisted fabric used is 40 pure cotton yarns with normal twist, and the twist is 22T / in; the strong twist yarn used is 40 pure cotton, with a twist of 25.3T / in.

Embodiment 2

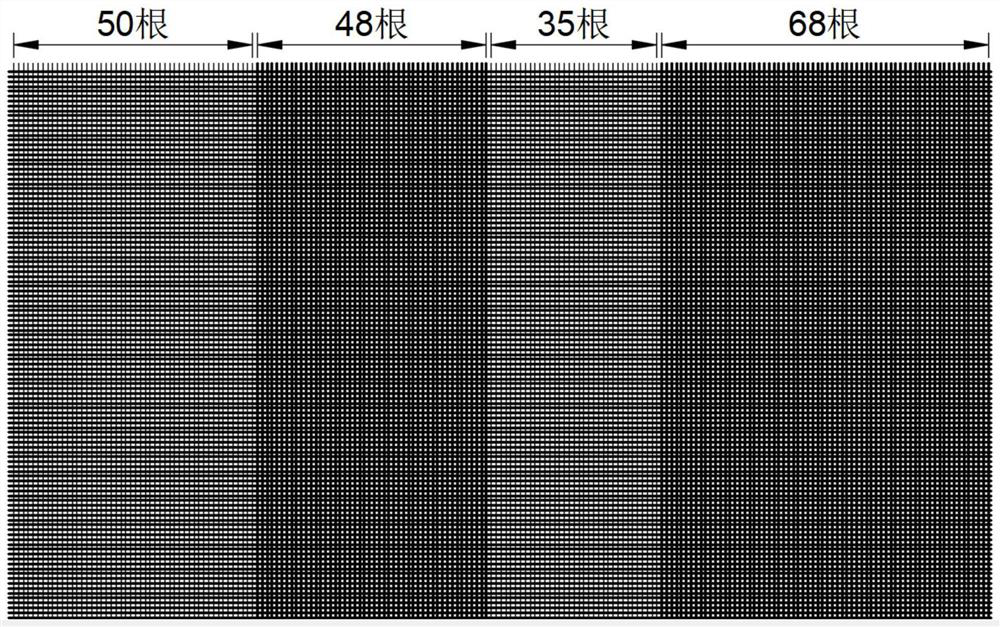

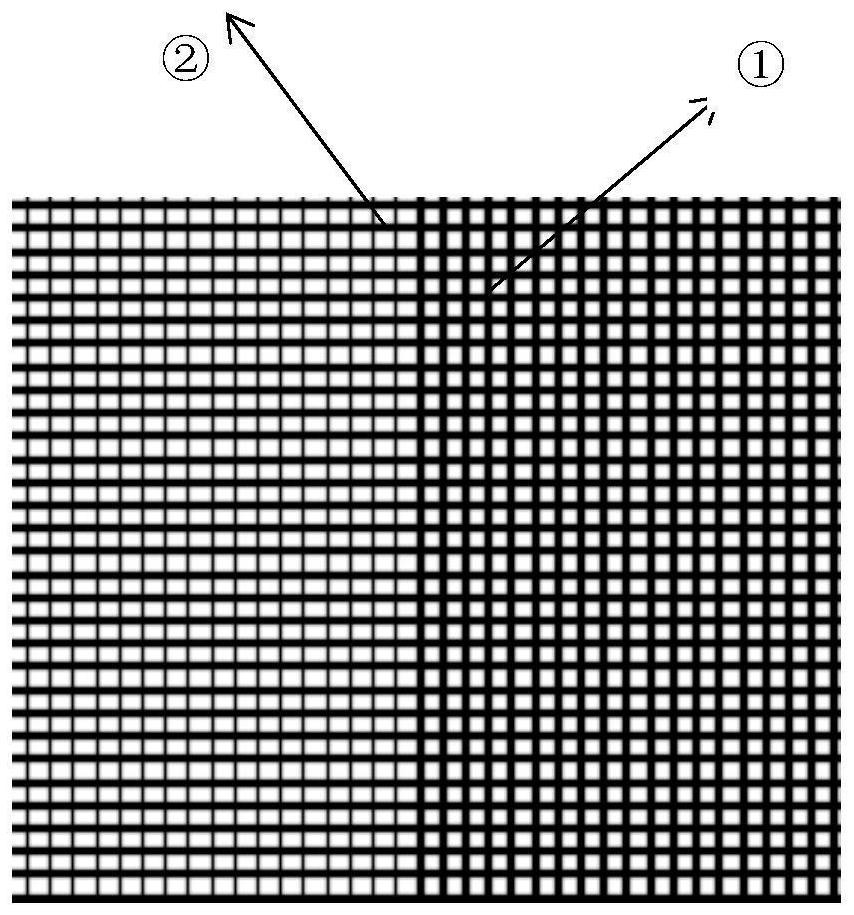

[0026] Such as figure 1 As shown, in the embodiment of the present invention, a yarn arrangement based on the cross-twisted fabric described in Embodiment 1 includes normal twisted yarns and strong twisted yarns with the same fineness and twist changes, and it can be clearly seen that dark shades of different shades are produced. pattern. The arrangement of one section of 22cm is: strong twisted yarn (50 pieces)-normal twisted yarn (48 pieces)-strong twisted yarn (35 pieces)-normal twisted yarn (68 pieces); figure 2 Shown is a schematic diagram of the intersection of different twists, ① is the normal twist yarn, ② is the strong twist yarn, it can be clearly seen that the gap between the yarn and the yarn is different, which explains the problem of the air permeability difference.

Embodiment 3

[0028] Based on the production method of the cross-twisted fabric described in embodiment 2, the steps are as follows:

[0029] (1) The fibers are processed into spun yarns that meet the requirements through the spinning process, and the spun yarns are spun by a ring spinning machine equipped with a variable twist yarn control device to obtain strong twisted yarns, normal twisted yarns and weakly twisted yarns with different twists Wire;

[0030] (2) According to the process design, the strong-twisted yarns, normal-twisted yarns and weak-twisted yarns of different twists are flexibly arranged according to the required fabric surface effect, and the warp and weft density of the fabric must not change;

[0031] (3) According to the process design, the weaving is completed on the loom to obtain the cross-twisted fabric.

[0032] In step (1), the yarn frame is spun into a siro spinning frame; in step (3), the loom used is a rapier loom.

[0033] Finally, the national standard wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com