Slurry supply pipe repair device and repair process thereof

A technology for feeding and repairing parts, applied in the field of repairing device for pulp supply pipe and its repairing process, can solve the problems of damage of internal rubber lining, reduction of production efficiency, outflow of slurry, etc., so as to increase service life, reduce outflow of slurry, and ensure smoothness Qi effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

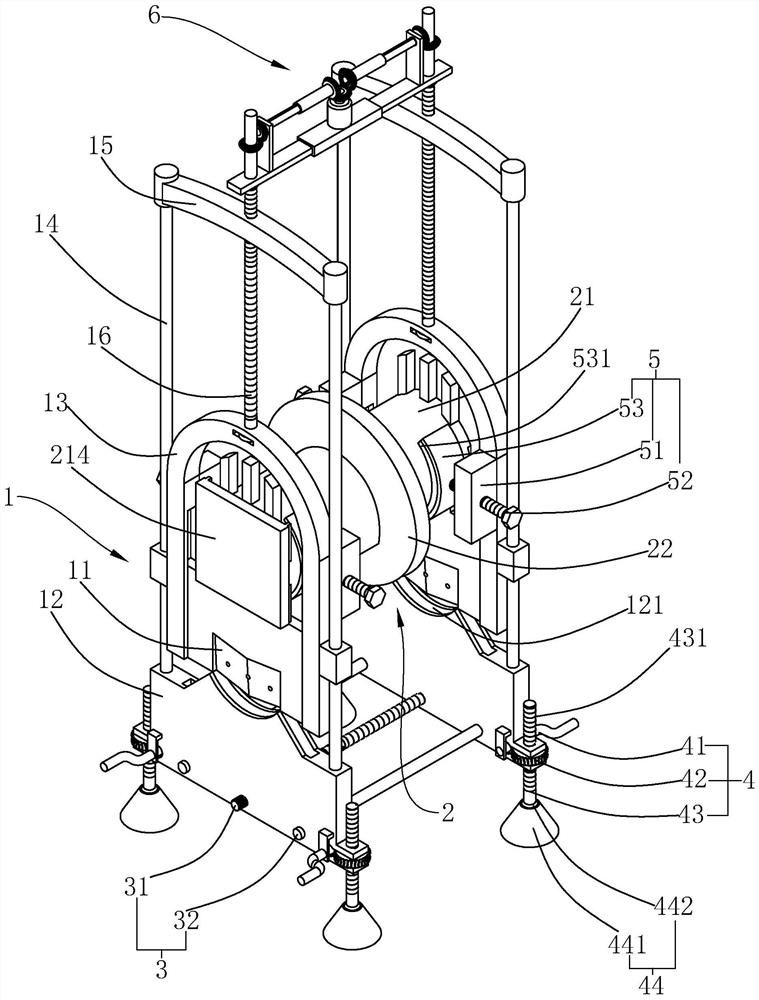

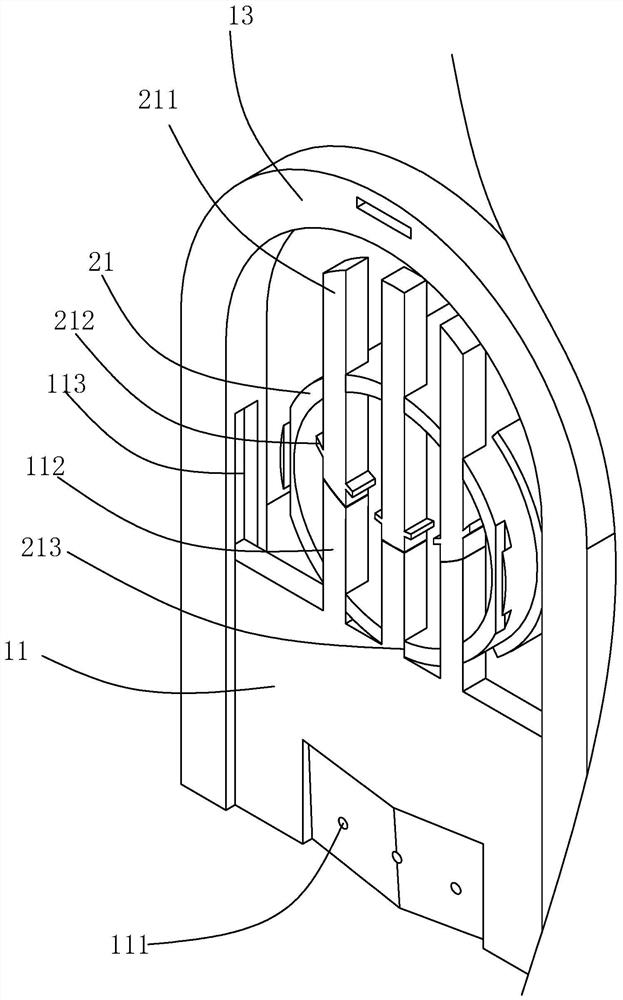

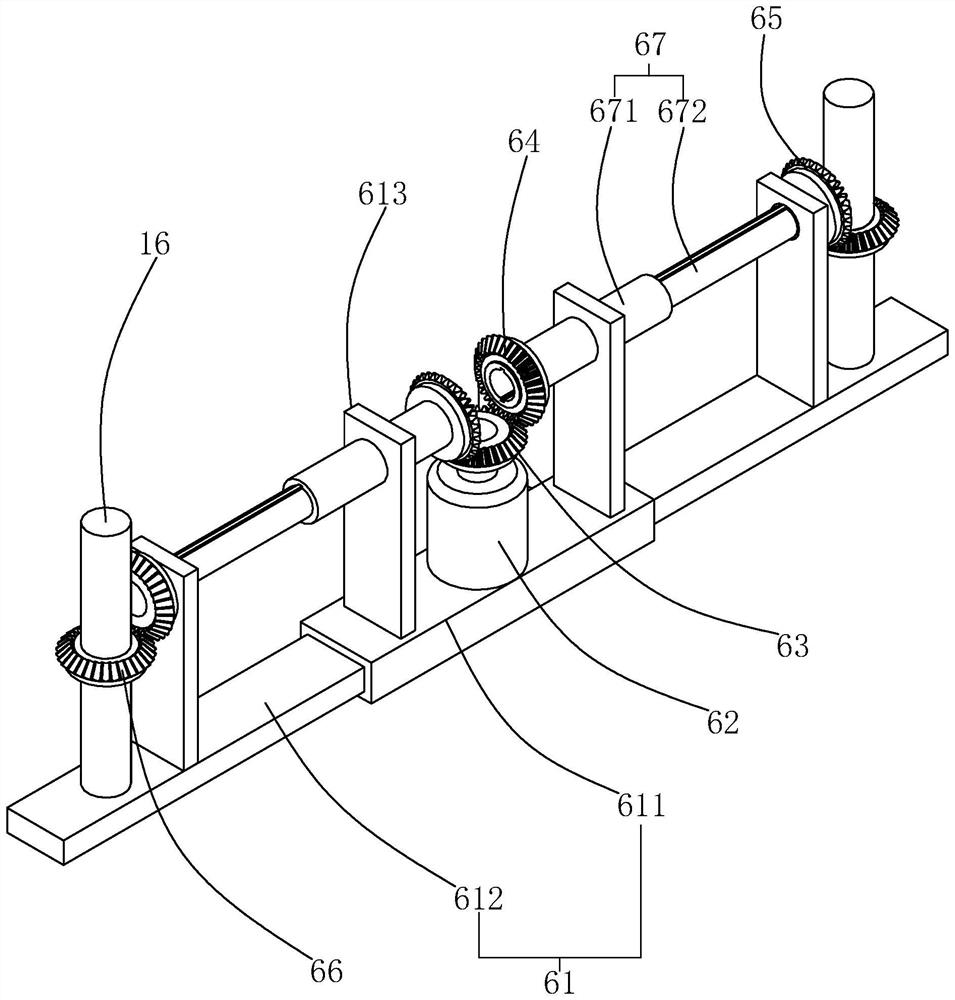

[0047] refer to figure 1 , is a slurry supply pipe repairing device disclosed in the present invention, comprising a cutting mechanism 1 for cutting a slurry leakage pipeline. The cutting mechanism 1 includes two sets of identical cutting parts respectively placed at both ends of the slurry leakage pipeline. Each set of cutting parts includes a base 12 , two guide rods 14 , a top frame 15 , a cutting frame 13 , a cutting knife 11 and a driving rod 16 .

[0048] refer to figure 1 , the top surface and the bottom surface of the base 12 of the two groups of cutting parts are all on the same horizontal plane, and the bottom surface of the base 12 is a horizontal plane. The top surface of each base 12 is provided with a cutting groove 121 , and the cutting groove 121 extends along the length direction of the top surface of the base 12 . Both ends of the cutting groove 121 protrude vertically upwards, and the middle part of the cutting groove 121 is recessed, so that the cutting g...

Embodiment 2

[0071] On the basis of Example 1, the present invention discloses a repair process for a slurry supply pipe repair device, comprising the following steps:

[0072] S1. Incision: through the downward pressure of two cutting knives, the two ends of the leakage pipeline are respectively cut into openings;

[0073] S2. Drainage: After the cutting knife cuts the opening, a part of the cutting knife will be placed in the pipeline. At this time, the slurry in the original pipeline and the leakage pipeline will flow to the stainless steel docked with the cutting knife under the drainage effect of the guide groove. tube;

[0074] S3, full cutting: through the continuous downward pressure of the two cutting knives, the two ends of the leakage pipeline are completely cut;

[0075] S4. Alignment: the stainless steel pipe moves down with the cutting knife until the two ends of the stainless steel pipe are aligned with the ports of the original pipe and fit neatly;

[0076] S5. Welding: b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com