A kind of semiconductor mesa metal stripping method

A metal lift-off and semiconductor technology, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of difficulty in ensuring the flatness of the photoresist, affecting the metal lift-off process, and poor film thickness uniformity, so as to avoid film thickness The effects of poor uniformity, reduced thickness requirements, and pollution avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

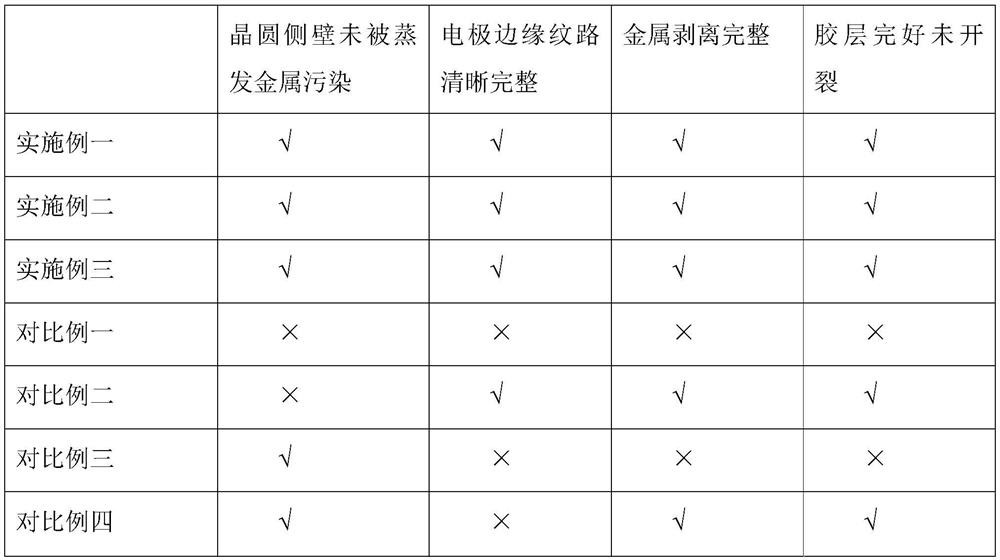

Embodiment 1

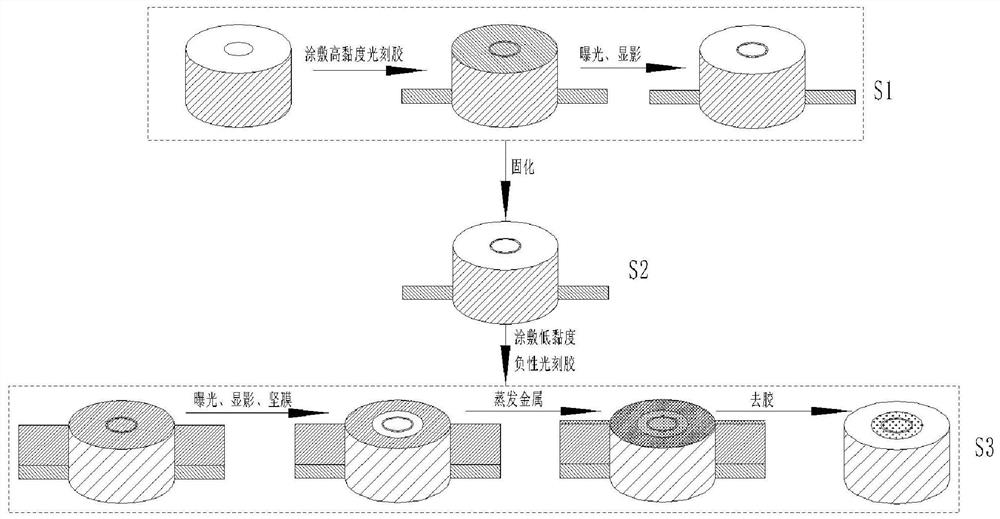

[0043] This embodiment discloses a semiconductor mesa metal stripping method, including the following steps:

[0044] S1 uses high-viscosity photoresist to apply glue to the wafer table and periphery, and then performs exposure, development, and glue removal operations in sequence to retain the high-viscosity photoresist on the periphery and the high-viscosity photoresist in the scribing lane of the table;

[0045] Among them, the viscosity of the high-viscosity photoresist is 1400cP, the coating thickness of the high-viscosity photoresist on the mesa is 1um, and the thickness of the peripheral coating is 5um.

[0046]The high-viscosity photoresist is a positive photoresist, and only the mesa area is exposed during the exposure process, and a mask is used to block the scribe line.

[0047] S2 heating and baking the wafer obtained in step S1 to cure the high-viscosity photoresist at a heating temperature of 140° C. for 40 minutes.

[0048] S3 uses a low-viscosity negative phot...

Embodiment 2

[0052] This embodiment discloses a semiconductor mesa metal stripping method, including the following steps:

[0053] S1 uses high-viscosity photoresist to apply glue to the wafer table and periphery, and then performs exposure, development, and glue removal operations in sequence to retain the high-viscosity photoresist on the periphery and the high-viscosity photoresist in the scribing lane of the table;

[0054] Among them, the high-viscosity photoresist is polyfiber PI positive photoresist, the specific model is PW-1500, the viscosity is 1500cP, and it has high temperature resistance. 6um.

[0055] During the exposure process, only the mesa area is exposed, and a mask is used to block the scribe lane.

[0056] S2 heating and baking the wafer obtained in step S1 to cure the high-viscosity photoresist at a heating temperature of 150° C. for 30 minutes.

[0057] S3 uses a low-viscosity negative photoresist to apply glue to the wafer table and periphery obtained in the step ...

Embodiment 3

[0061] This embodiment discloses a semiconductor mesa metal stripping method, including the following steps:

[0062] S1 uses high-viscosity photoresist to apply glue to the wafer table and periphery, and then performs exposure, development, and glue removal operations in sequence to retain the high-viscosity photoresist on the periphery and the high-viscosity photoresist in the scribing lane of the table;

[0063] Among them, the viscosity of the high-viscosity photoresist is 1600cP, which has high temperature resistance. The thickness of the high-viscosity photoresist on the table is 3um, and the thickness of the peripheral coating is 7um.

[0064] During the exposure process, only the mesa area is exposed, and a mask is used to block the scribe lane.

[0065] S2 heating and baking the wafer obtained in step S1 to cure the high-viscosity photoresist at a heating temperature of 160° C. for 20 minutes.

[0066] S3 uses a low-viscosity negative photoresist to apply glue to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com