Film automatic stripper

An automatic peeling, dielectric film technology, applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve problems such as low work efficiency, high labor intensity, damage to useful graphics, etc., to achieve convenient operation, reduce labor the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

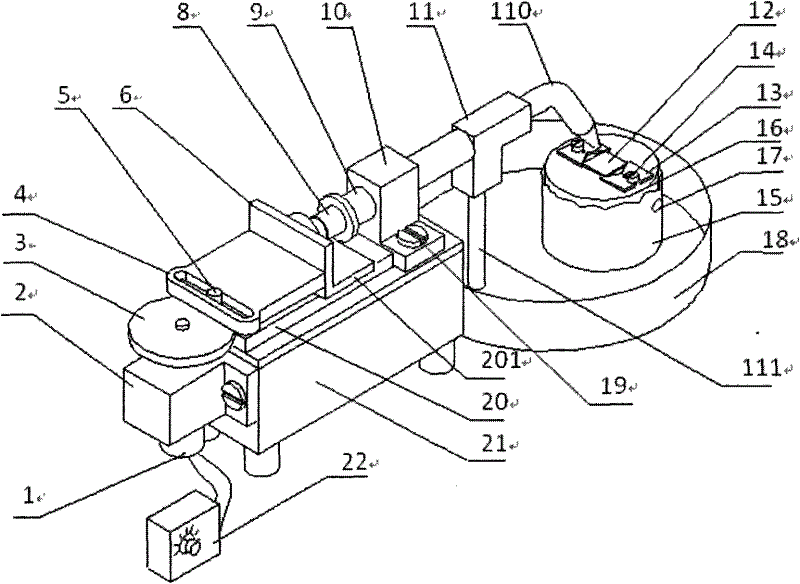

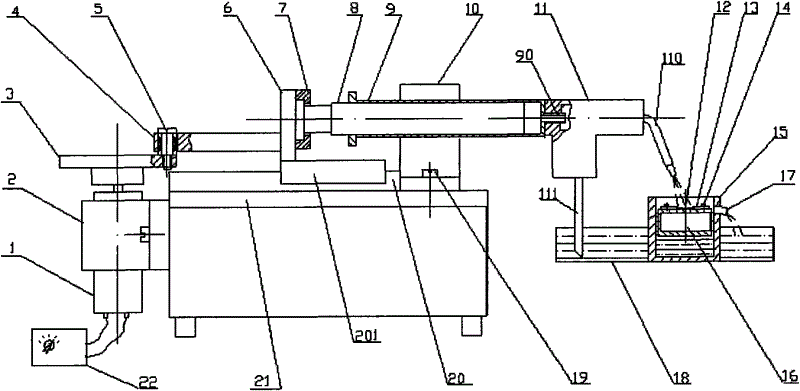

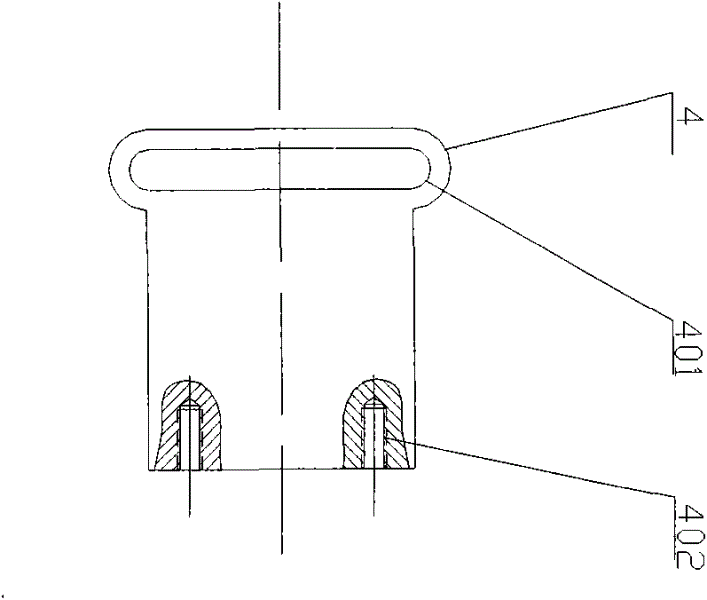

[0016] The following is based on Figure 1-Figure 6 Examples of the present invention are illustrated. and describe in detail.

[0017] Such as figure 1 ---- Figure 6 As shown, the embodiment of the present invention includes; the DC motor 1 is fixed vertically upward through the frame 2 on the center line of the vertical plane at one end of a rectangular cube support 21 with screws. The motor 1 adjusts the rotational speed through the power supply 22 . Metal dial 3 is housed on the rotating shaft of motor upper end, and the edge of dial plane is fixed with driving rod 5, and driving rod is vertical upwards, and metal dial 3 and metal driving rod 5 are all made of metal material. Described rectangular cube support 21 is spliced with 6 pieces of metal plates such as aluminum plates, and its upper plane has a ball linear guide 20 along the horizontal position of the center line, and a driving plate 4, a vertical plate 6, Piston 8, cylinder body 9, pump 11. A liquid stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com