Method for preparing graphene composite conductive paste by microwave-ultrasonic and products obtained therefrom

A technology of graphene composite and conductive paste, which is applied in the direction of chemical instruments and methods, circuits, carbon compounds, etc., can solve the problems of sheet thickness, easy agglomeration, poor stability of paste, etc., and achieve improved conductivity and small viscosity changes , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

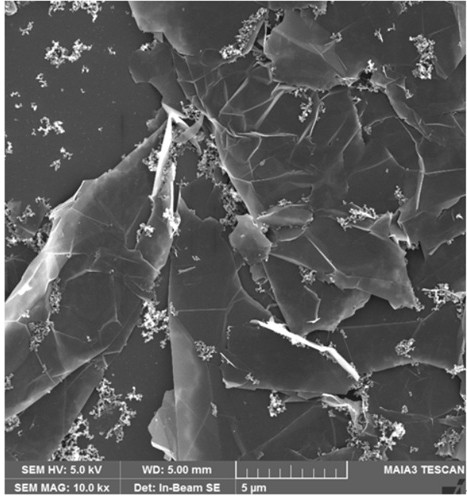

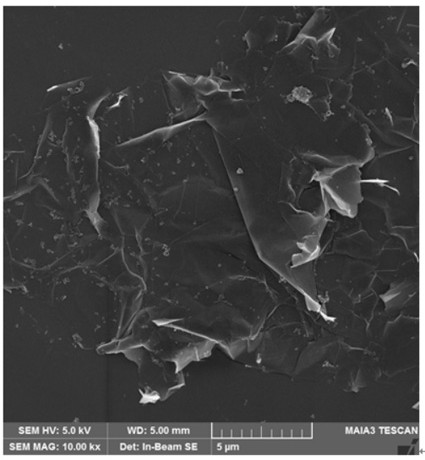

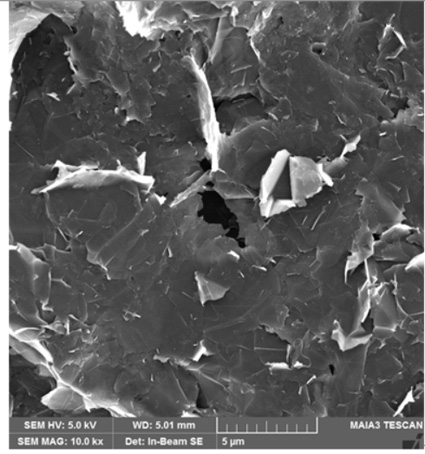

[0046] Weigh 2000 mesh flake graphite, use potassium permanganate as oxidant, concentrated sulfuric acid and potassium permanganate as intercalation agent (the mass ratio of flake graphite, potassium permanganate and concentrated sulfuric acid is 1:1:4) in a water bath at 35 °C, stirred for 60 min for acidification intercalation. After acidification and intercalation, wash with 5% dilute hydrochloric acid deionized water to neutral in turn, and use suction filtration to put the expandable graphite suspension washed to neutral into the Buchner funnel of the suction filter bottle, and use qualitative filter paper Suction filtration, the filter cake is left on the filter paper, and the filtrate enters the suction filtration bottle. The filter cake was vacuum-dried at 60 °C for 16 h to obtain expandable graphite. The expandable graphite was put into a microwave reactor, and under a nitrogen protective atmosphere, the power was controlled at 1500W for microwave expansion treatment...

Embodiment 2

[0055] Weigh 2000 mesh flake graphite, use potassium permanganate as oxidant, concentrated phosphoric acid and potassium permanganate as intercalation agent (mass ratio of flake graphite, potassium permanganate and concentrated phosphoric acid is 5:1:4), in a water bath Stir at 35°C for 60 min for acidification intercalation. Wash with 8% dilute hydrochloric acid and deionized water until neutral, and use suction filtration to put the expandable graphite suspension washed to neutral into the Buchner funnel of the suction filter bottle, and use qualitative filter paper for suction filtration. The filter cake is left on the top, and the filtrate enters the suction filter flask. Vacuum-dry the filter cake at 100°C for 24 hours to obtain expandable graphite. Put the expandable graphite into a microwave reactor, and in a nitrogen atmosphere, control the power to 500W for microwave expansion treatment for 200s to obtain expanded graphite. 0.25g of expanded graphite obtained in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com