Unstacking device, unstacking system and unstacking method

A technology of cargo stacking and conveying mechanism, which is applied in the field of unstacking devices, and can solve the problems of bagged goods shape, size not fixed, height fluctuation of bagged goods in the same layer, failure of unstacking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

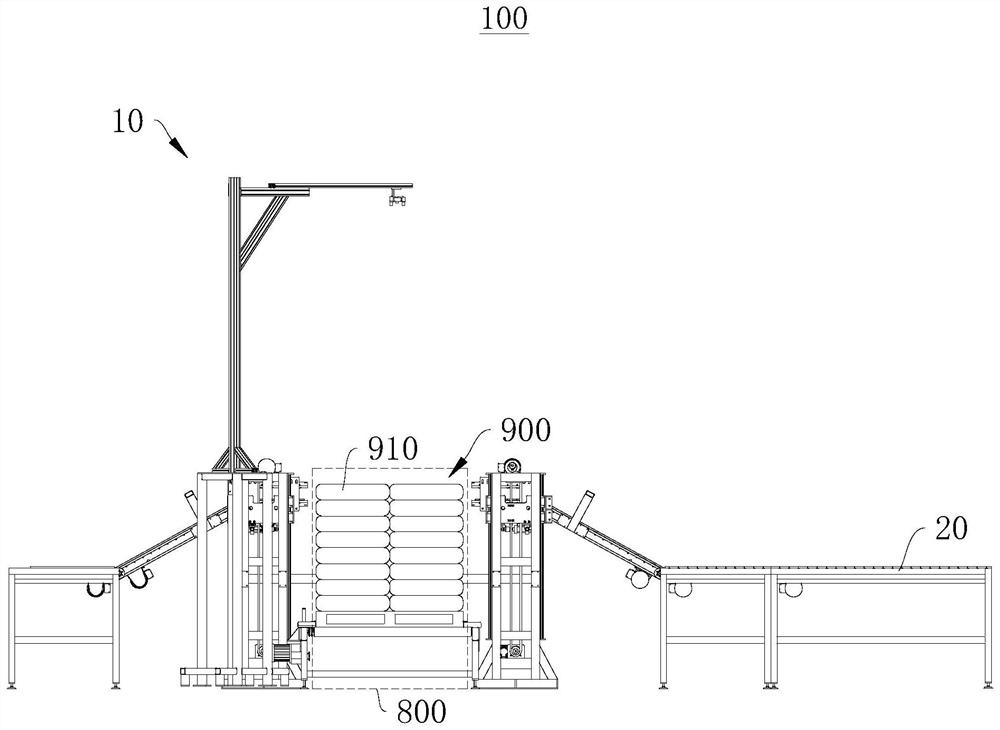

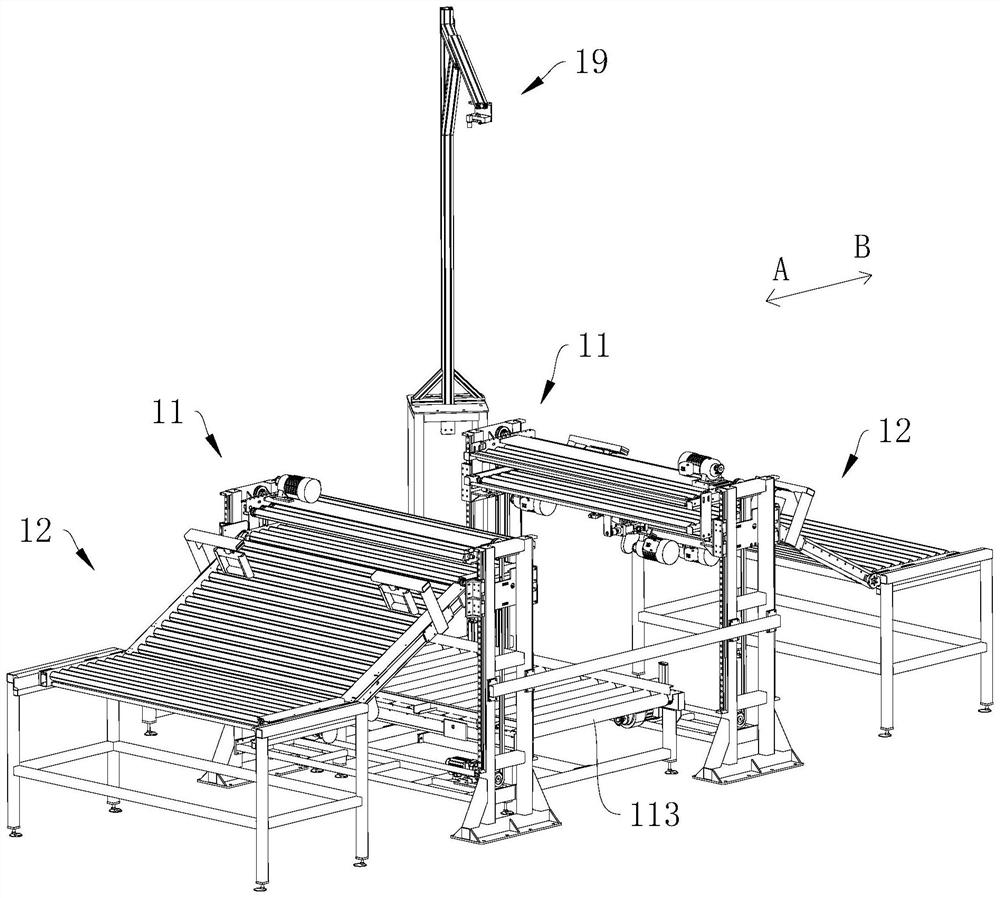

[0042] see figure 1 , figure 1 It is a structural schematic diagram of the application of the depalletizing device 10 in the depalletizing system 100 provided by the first embodiment of the present invention.

[0043] The first embodiment of the present invention provides a depalletizing device 10, the depalletizing device 10 is used to perform depalletizing operation on the cargo stack 900 formed by the bagged goods 910, and it has the stability to perform the depalletizing operation on the bagged goods 910 Higher, and the efficiency of destacking is higher. The depalletizing device 10 can be applied to a depalletizing system 100 , a loading system, a storage system, etc. Of course, the depalletizing device 10 can also be used independently.

[0044] Taking the depalletizing device 10 applied to the depalletizing system 100 as an example, the depalletizing system 100 includes the depalletizing device 10, which performs the depalletizing operation on the cargo stack 900 thro...

no. 2 example

[0090] see Figure 10 , Figure 10 It is a schematic flow chart of the unstacking method provided by the second embodiment of the present invention.

[0091] The second embodiment of the present invention provides a depalletizing method. The depalletizing method has the characteristics of high stability and high depalletizing efficiency for bagged goods 910 . This depalletizing method can be applied to the above-mentioned depalletizing device 10 and depalletizing system 100 .

[0092] It should be noted that the basic principles and technical effects of the unstacking method provided in this embodiment are the same as those of the above-mentioned embodiments. For a brief description, the part not mentioned in this embodiment can refer to Corresponding content.

[0093] The depalletizing method includes:

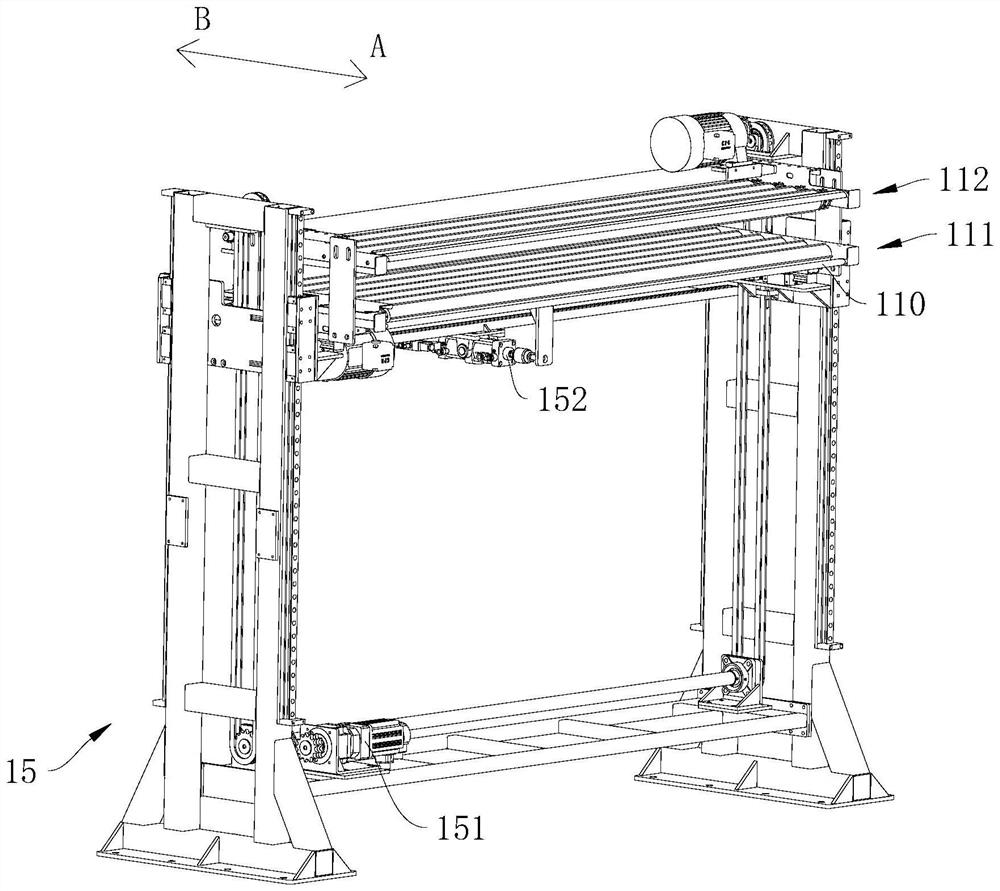

[0094] Step S100: the unstacking moving mechanism 15 drives the first unstacking conveying mechanism 111 up and down, so that the starting end of the first unstacking con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com