Sample cigarette closed-loop circulation management system and method and intelligent cigarette clamps

A cigarette clamp and intelligent technology, applied in the field of sample smoke closed-loop circulation management system, can solve the problem that the specific flow direction of sample smoke is difficult to be grasped

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

[0033] An embodiment of a sample smoke closed-loop circulation management system of the present invention:

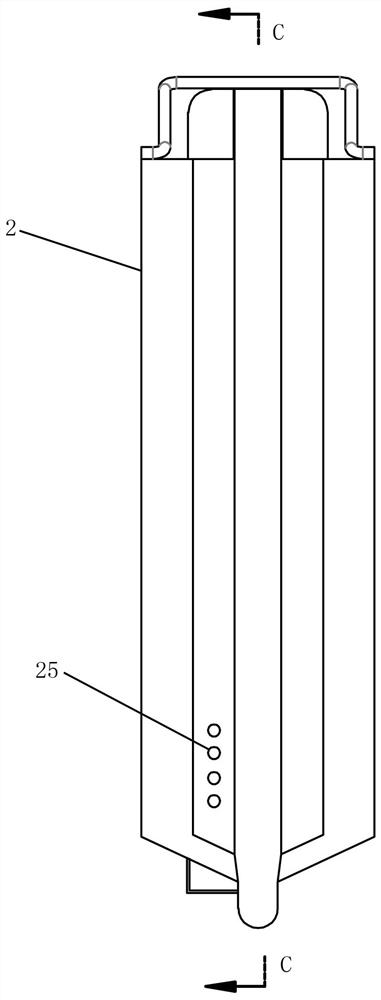

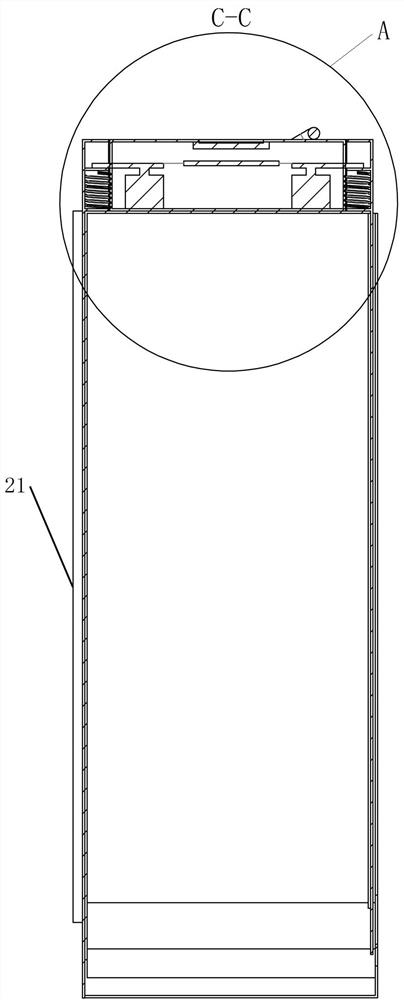

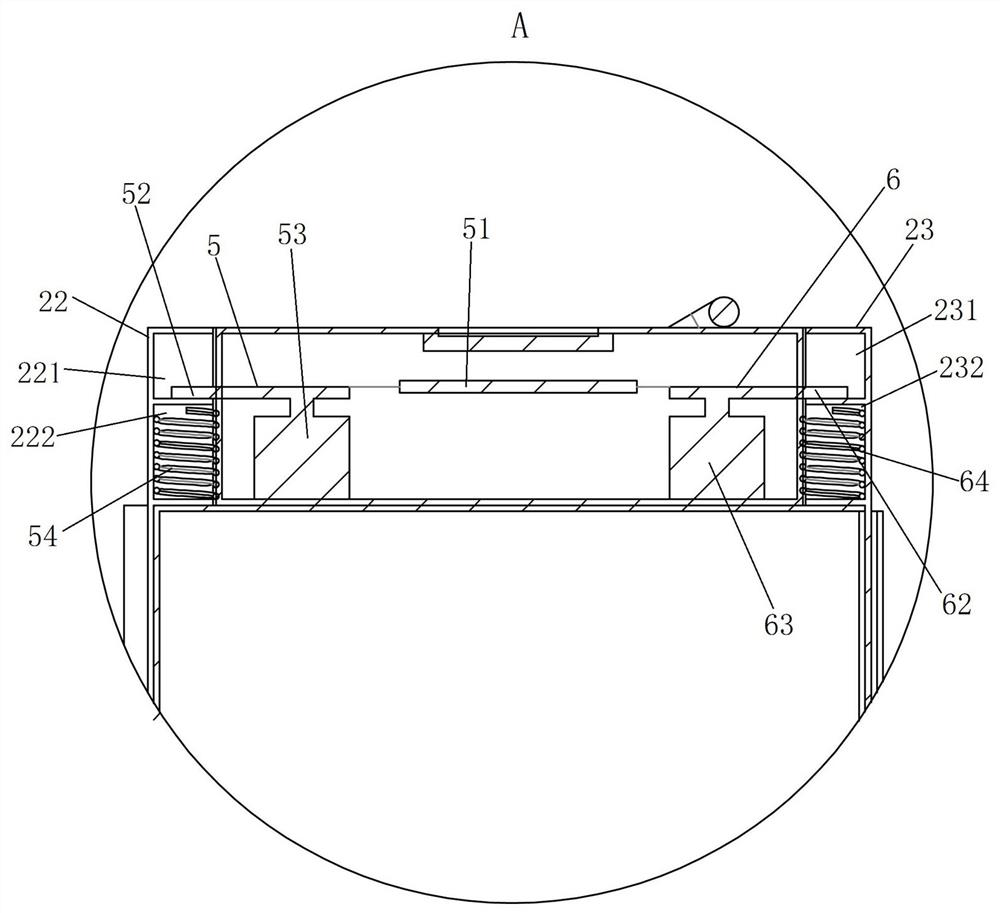

[0034] The specific structure of a sample smoke closed-loop circulation management system of the present invention is as follows: Figure 1 to Figure 8 As shown, it includes the main unit 1, the smart cigarette clip 2, the upper pod clip seat and the suction machine seat 4. The host 1 includes a signal storage module and a signal receiving module, and the smart cigarette holder 2 is provided with a two-dimensional code. In this embodiment, the host 1 is an intelligent all-in-one machine including a display screen, which is integrated with a signal receiving module for receiving signals through WIFI, and the two-dimensional code of the smart cigarette clip 2 is displayed on the display screen. In other embodiments, the two-dimensional code can also be written on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com