One-way locking and pressurizing knotting-loop-free steel plate fixing structure

A one-way locking and fixing structure technology, applied in the direction of fixator, outer plate, internal bone synthesis, etc., can solve the problems of cumbersome operation, easy local wire knot reaction, loss of pressurization effect, etc., to increase stability and Reliability, reduce local wire knot foreign body reaction and discomfort, and avoid partial loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

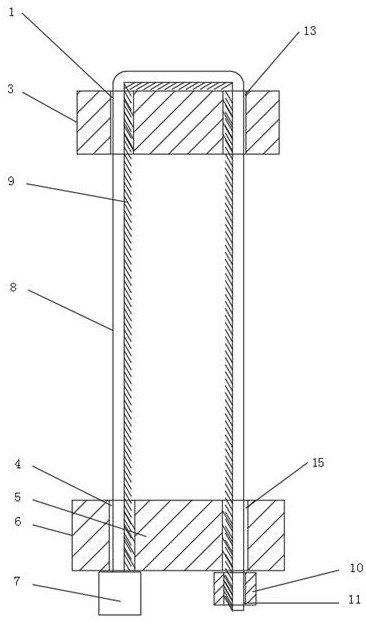

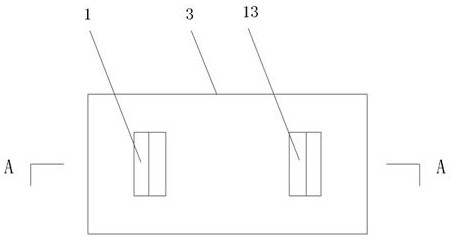

[0027] Such as Figure 1 to Figure 8 As shown, a unidirectional locking pressurization knot-free loop plate fixation structure of the present invention includes a loop plate 3 on the opposite side of fracture dislocation, a loop plate 6 on the side of the surgical incision, a loop line and a tail cap 10,

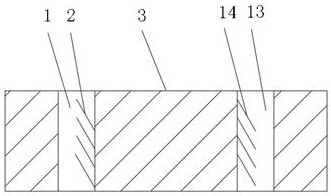

[0028] A first through hole 1 and a second through hole 13 are provided on the loop plate 3 on the opposite side of the fracture dislocation, and the two opposite inner sides of the first through hole 1 and the second through hole 13 are along the opposite side of the fracture dislocation. At least four first locking teeth 2 and second locking teeth 14 are arranged at intervals in the thickness direction of the loop steel plate 3, and the first locking teeth 2 and the second locking teeth 14 are respectively inclined to the first through hole 1 and the second through hole 13 inner side,

[0029] Described surgical incision side loop steel plate 6 is provided with a 3rd thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com