A shaking type material screening device

A screening device and material technology, applied in the fields of sieving, solid separation, chemical instruments and methods, etc., can solve the problems of unfiltered impurities accumulation, affecting the effect of material passing, and achieve the effect of promoting movement and improving screening efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

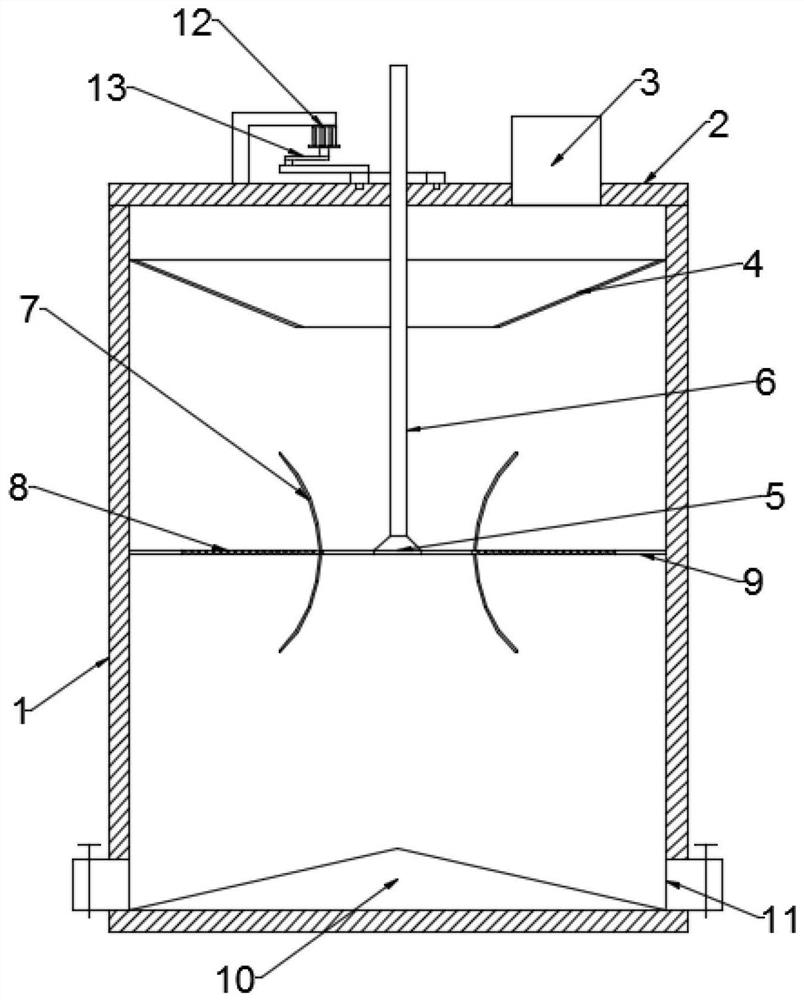

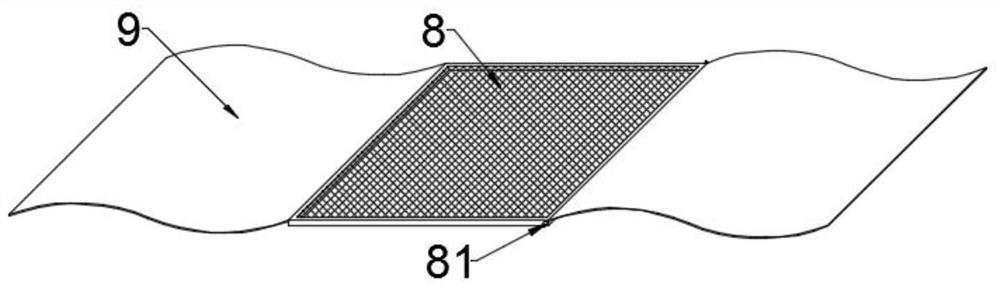

[0023] see Figure 1~3 , in an embodiment of the present invention, a vibrating material screening device includes a housing 1, a screening mechanism is installed in the housing 1, an upper cover 2 is installed on the housing 1, and the middle part of the screening mechanism The fixed connection is provided with a lifting backing plate 5, the lifting backing plate 5 and the inner wall of the housing 1 are slidingly fitted and connected, and the upper end of the lifting backing plate 5 is fixedly connected with a threaded rod 6, and the threaded rod 6 vertically slides through the As for the upper cover 2, the upper end of the upper cover 2 is installed with a drive mechanism that drives the threaded rod 6 to reciprocate vertically.

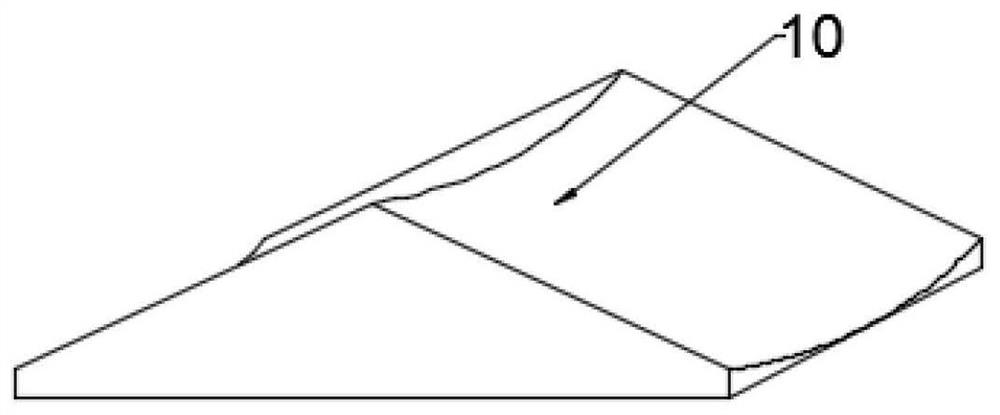

[0024] The housing 1 is a cuboid cavity structure, the bottom of both sides of the housing 1 is symmetrically provided with discharge pipes 11, the discharge pipe 11 is provided with a valve, and the bottom of the housing 1 is also fixedly connect...

Embodiment 2

[0030] see figure 1 and 4 , in the embodiment of the present invention, a vibrating material screening device, the driving mechanism includes a motor 12, the motor 12 is installed on the upper cover 2 through a bracket, the output end of the motor 12 is vertically downward, The end of the output end of the motor 12 is fixedly connected with a drive rod 13 , and the end of the drive rod 13 is slidably connected with a transmission assembly, and the transmission assembly is mated with the threaded rod 6 .

[0031] The transmission assembly includes a drive gear 14 movably connected to the periphery of the threaded rod 6 through threaded fit and a drive rack 15 symmetrically arranged on both sides of the drive gear 14. The upper end of the cover 2, the driving gear 14 and the transmission racks 15 on both sides are all meshed for transmission, the bottom of the transmission rack 15 is slidingly fitted and connected to the upper end of the upper cover 2, and the upper end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com