Front-back maintenance mechanism for LED display module

A display module, front and rear maintenance technology, applied in the direction of cabinet/cabinet/drawer parts, instruments, electrical components, etc., can solve the problems of affecting the display effect and waterproof, unable to adjust the locking, and unable to achieve front and rear maintenance at the same time. , to achieve the effect of fast front and rear maintenance, small number of structures, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described below with reference to the accompanying drawings and examples.

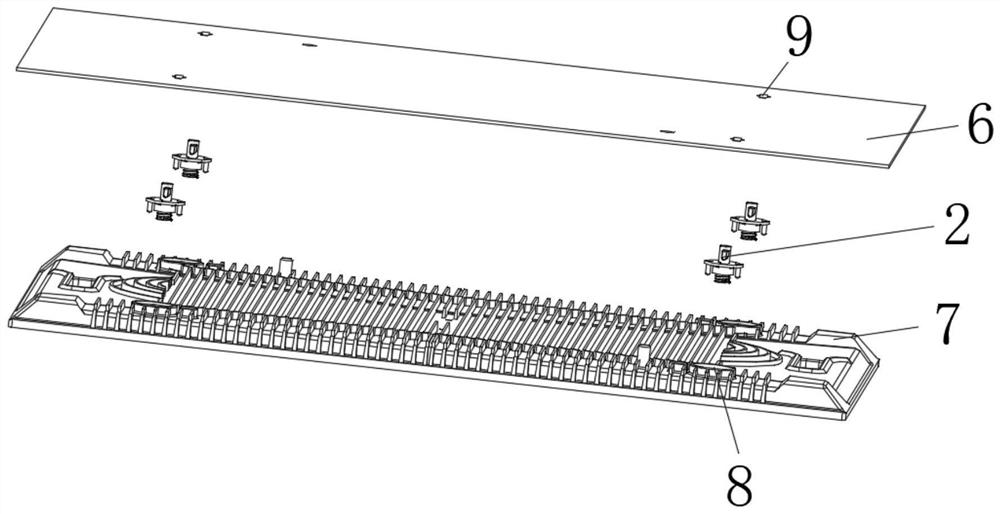

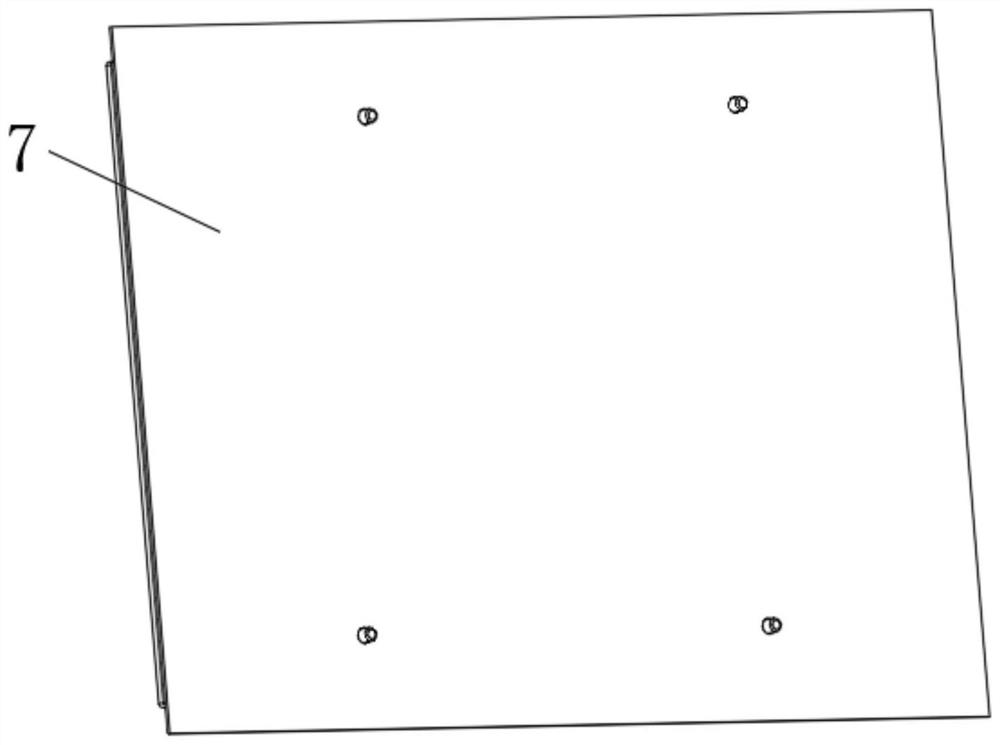

[0032] see Figure 1-8 , the present embodiment discloses a LED display unit box, which is mainly composed of a screen panel 6 and an LED display module 7, and also includes a front and rear maintenance mechanism for the LED display module. The screen panel 6 and the LED display module 7 are displayed through LEDs. The front and rear maintenance mechanisms of the module are detachably connected.

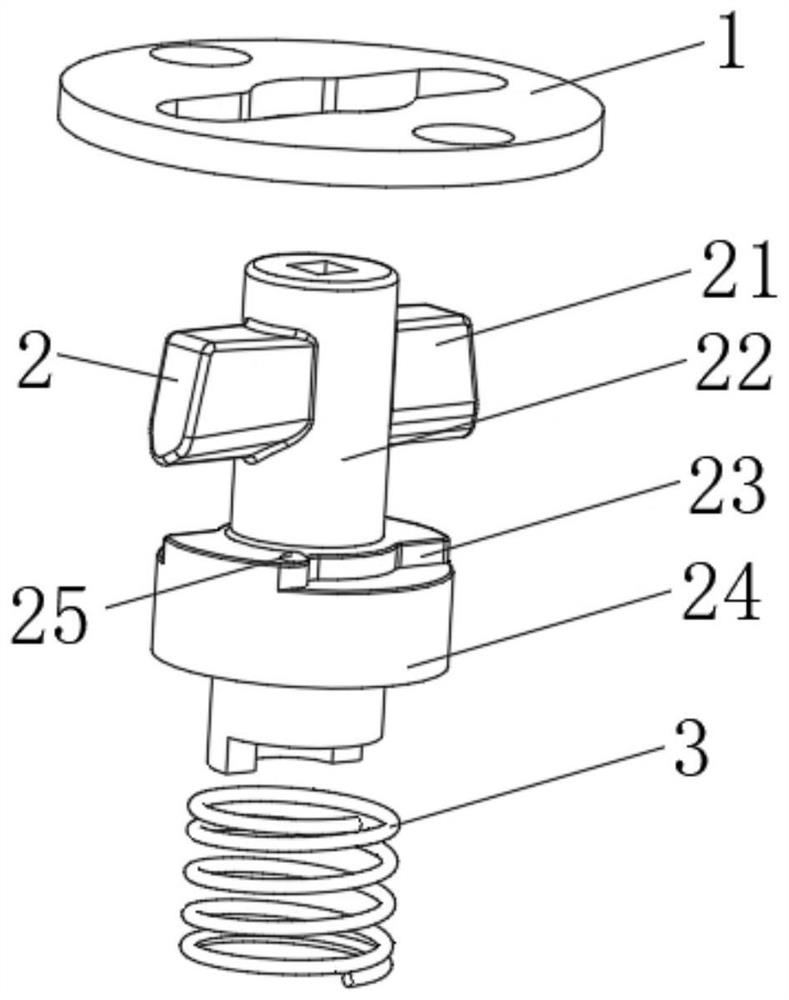

[0033] The front and rear maintenance mechanism of the LED display module includes a pressure plate 1 and a lock cylinder 2, the lock cylinder 2 includes a rotating rod 22, one end of the outer peripheral side of the rotating rod 22 is fixed with a side rod 21, and the other end of the outer peripheral side of the rotating rod 22 is provided with an elas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com