combing machine

A technology of combing machine and sliver, applied in the field of combing machine, can solve problems such as energy consumption, motor heating, motor life-span, motion control, response, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

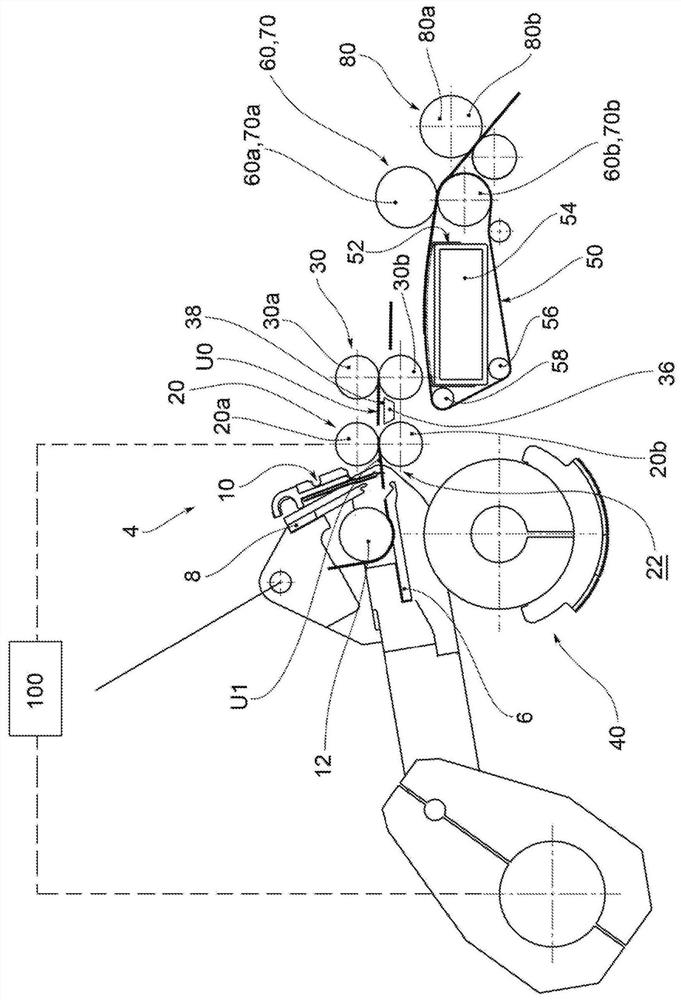

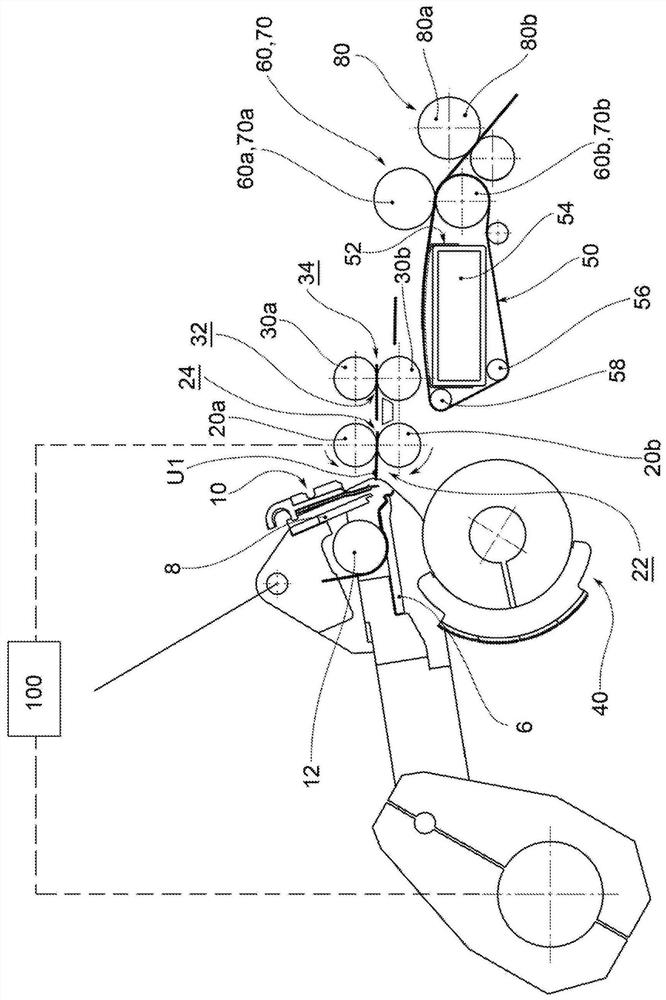

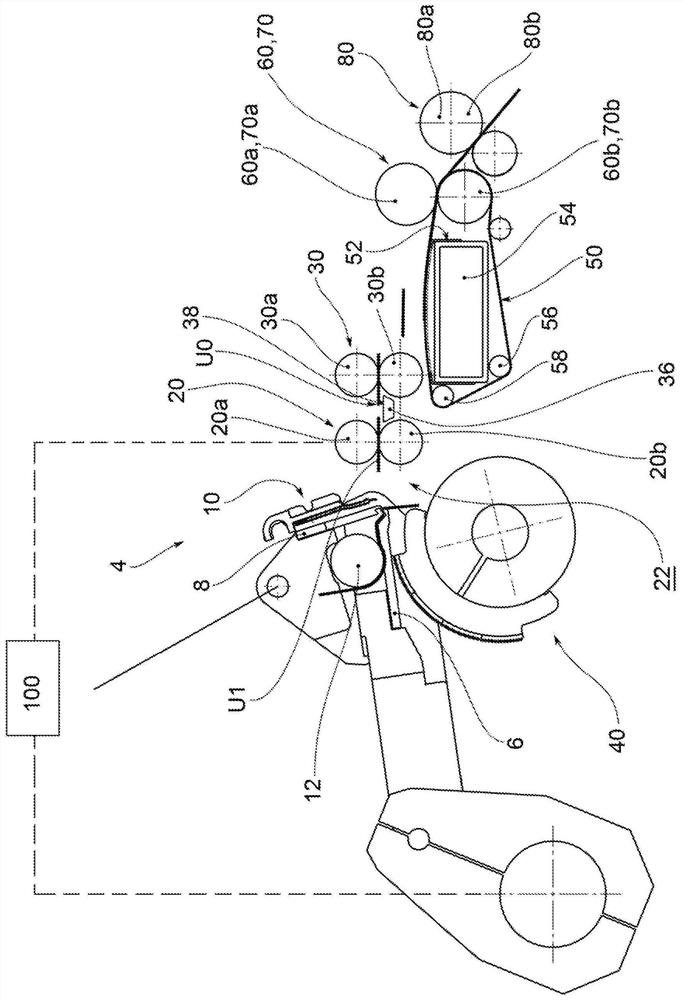

[0021] The combing machine according to the invention comprises a fixed frame and clamps 4 supported by the fixed frame.

[0022] The clamp 4 includes a lower jaw 6 , an upper jaw 8 and a straight comb 10 generally attached to the lower jaw 6 .

[0023] Furthermore, the gripper 4 includes a supply roller 12 supported by the lower jaw 6, which can be rotated intermittently on command.

[0024] The comber also includes a first pair of separation rolls 20 downstream of the nip 4, comprising an upper separation roll 20a and a lower separation roll 20b, which is typically pressure-coupled with the upper separation roll 20a and pulled in rotation therefrom.

[0025] Between said separating rollers 20a, 20b there is an inlet port 22 on one side of the gripper 4, which carries the sliver section that has been released by the supply roller 12, and an outlet port 24 on the other side.

[0026] The comber also includes a second pair of separation rolls 30 downstream of the first pair of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com