An easy-to-operate wheat disease weeding device

A technology for diseases and wheat, which is applied in the field of wheat disease weeding devices, can solve problems such as inability to apply pesticide spraying, inability to apply to fields of different sizes, inability to adapt to planting modes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

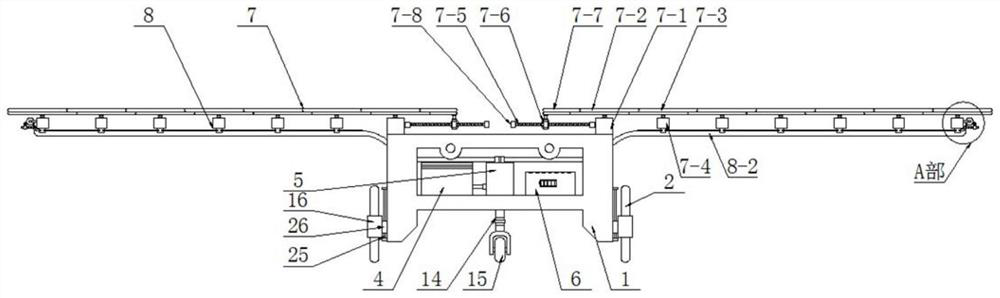

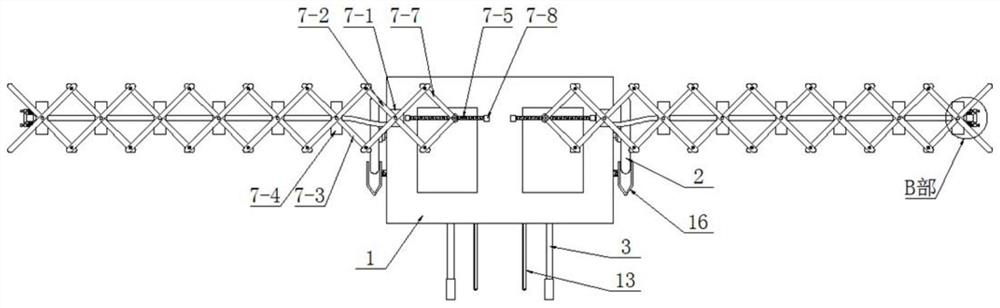

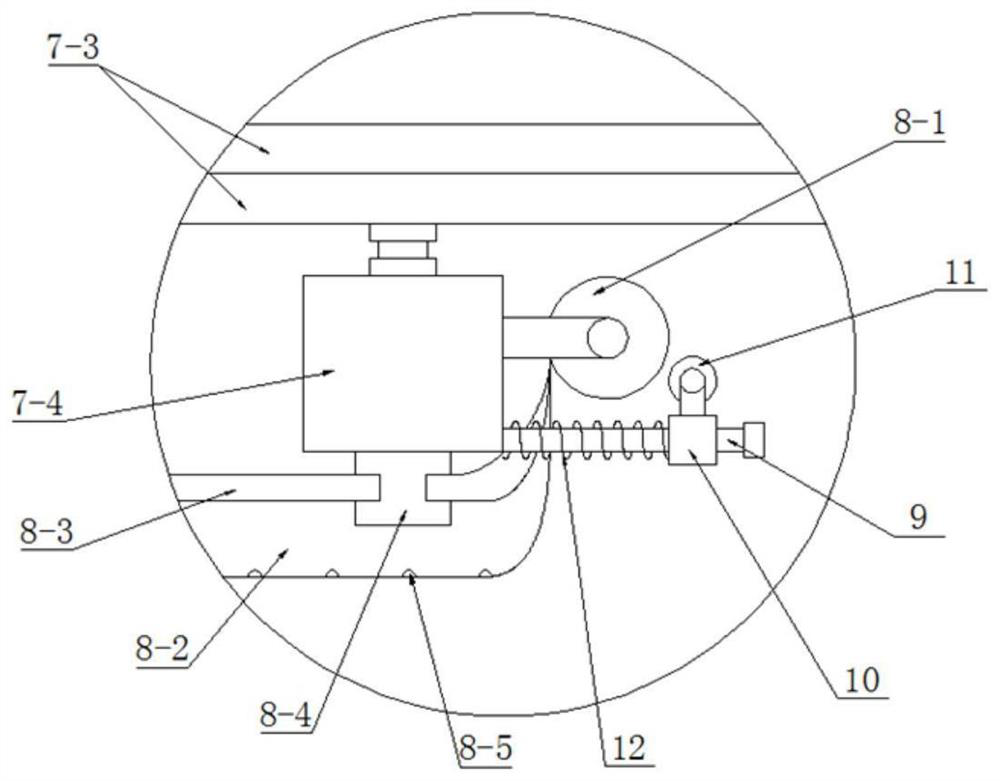

[0029] see as Figure 1-Figure 4 As shown, this specific embodiment includes a mounting seat 1, a traveling wheel 2, a water tank 4, a booster pump 5, a support assembly 7, and a spray assembly 8, wherein the lower ends of the left and right sides of the mounting seat 1 are screwed with a traveling wheel 2 through bearings The lower end of the front side wall of the mounting seat 1 is provided with a support seat 14 through a bearing, and the lower end of the support seat 14 is provided with a support wheel 15 through a bearing, and the mounting seat 1 is supported by the support wheel 15 to prevent the mounting seat 1 from toppling over. When seat 1 turns during the advancing process, support wheel 15 rotates and changes direction by support frame, and the bearing on mounting seat 1 is provided with No. 2 screw mandrel 25, and the screw screw sleeve on No. 2 screw mandrel 25 is provided with fixed block 26, and guide plate 16 is fixed on the fixed block 26, and the rear side ...

specific Embodiment approach 2

[0037] see as Figure 5 to Figure 8 As shown, the difference between this specific embodiment and the first specific embodiment is that: the screw 7-8 is replaced by a sleeve 17, and a double output reversing reducer 18 is riveted on the mounting base 1, and the double output reversing reducer 18 is riveted. The output shaft of the reducer 18 is riveted with a No. 1 rotating shaft 19, the movable end of the No. 1 rotating shaft 19 is inserted in the sleeve 17, and the outer wall of the sleeve 17 is screwed with a No. 2 rotating shaft 20 through a bearing. On the second rotating shaft 20, a guide ring 21 is riveted, and a pin rod 22 is movable in the guide ring 21. On the first rotating shaft 19, a pin hole 23 is provided. After the pin rod 22 passes through the side wall of the sleeve 17, Movably insert in pin hole 23, be provided with torsion spring 24 on the No. 2 rotating shaft 20, a column foot of torsion spring 24 is riveted on the sleeve 17, and another column foot of to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com