Front axle assembly with shock absorber assisting in absorbing side impact energy

A technology for shock absorbers and front axles, applied to axles, brakes, cooling brakes, etc., can solve problems such as poor safety and achieve good side impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

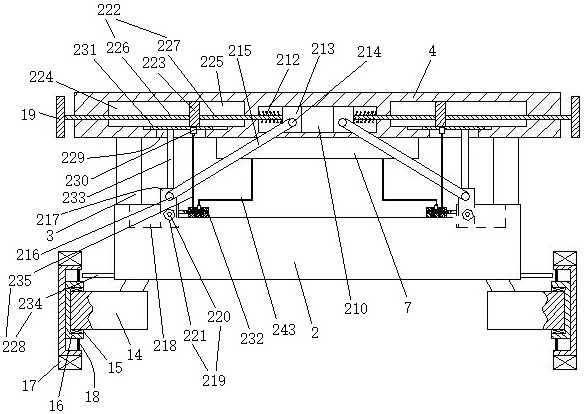

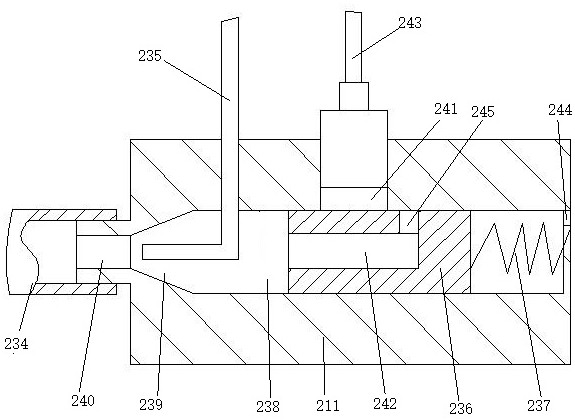

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0019] see figure 1 and 2, a front axle assembly in which a shock absorber assists in absorbing side impact energy, including a front axle 2, a shock absorber 3, a front beam 4 and a water tank 7. Both ends of the front axle are connected with steering knuckles 14 . The steering knuckle is connected with a wheel connecting sleeve 16 through a bearing 15 . The front wheel 17 and the front brake disc 18 are connected on the wheel connecting sleeve (the front brake disc cooperates with the front brake caliper to brake the front wheel). The present invention also includes two longitudinal bumpers 19 distributed on both sides in the longitudinal direction of the front axle. The two ends of the front cross member are respectively supported on the two ends of the front axle by a shock absorber. The longitudinal bumper is connected with the front cross m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com