Pneumatic separation nut device

A pneumatic separation and nut technology, applied in the direction of nuts, screws, bolts, etc., can solve the problems of poor synchronization, short unlocking time, large impact, etc., and achieve the effect of small impact response, short unlocking time and good synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

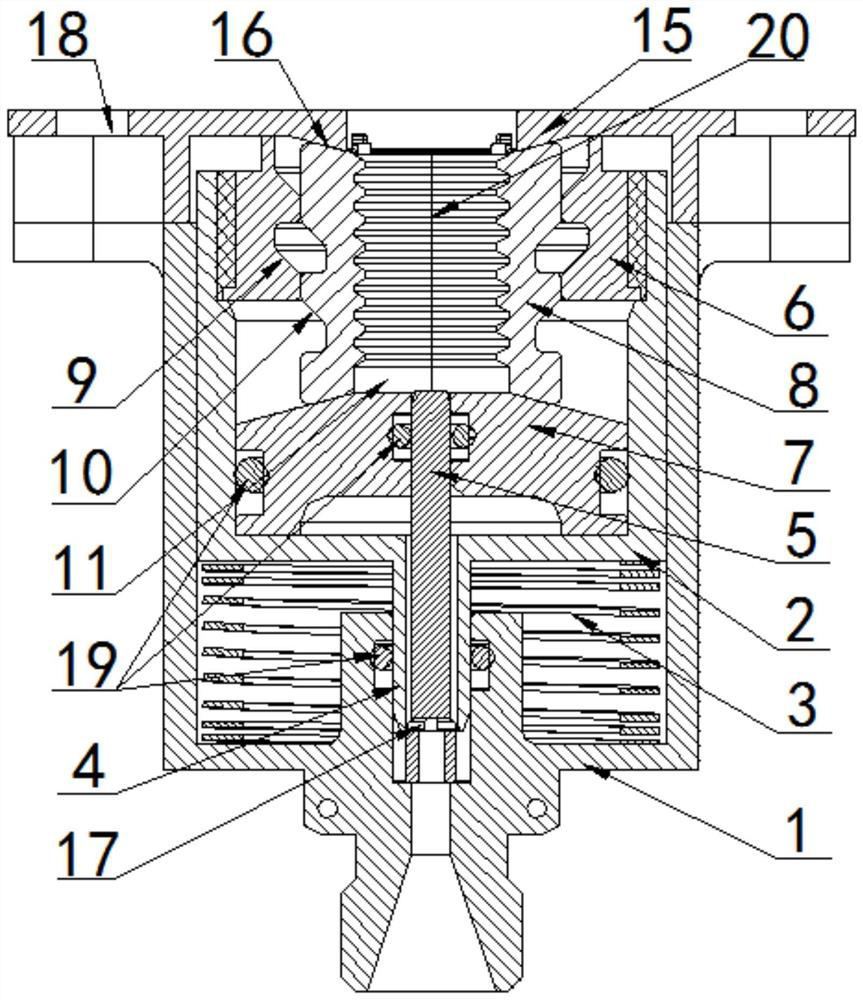

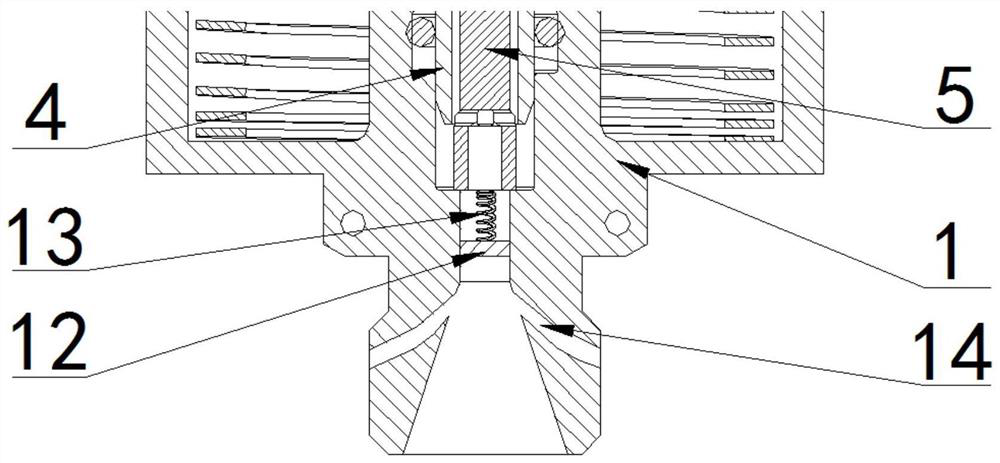

[0025] A pneumatic separation nut device, comprising: an outer shell 1 with a hollow interior, an inner cavity 2 arranged inside the outer shell, a separation assembly arranged inside the inner cavity 2 and a vertically arranged between the outer shell 1 and the inner cavity 2 The spring 3 between; the inner cavity 2 can slide up and down in the outer shell 1;

[0026] One end of the outer shell 1 is axially provided with a first through hole communicating with the outside, and one end of the inner cavity 2 is provided with an air inlet 4 extending axially, and the air inlet 4 penetrates the first A through hole; the air inlet portion 4 is provided with a second through hole communicating with the interior of the inner cavity 2, and the second through hole communicates with the first through hole; the air inlet portion 4 is axially provided There is a striker 5, one end of the striker 5 extends into the inner cavity 2, and the other end extends out of the air inlet 4, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com