A split memory alloy spring pin

A memory alloy spring and memory alloy technology, applied in bolts and other directions, can solve the problems of limited bearing capacity of the pin puller, large unlocking impact, small locking force, etc., and achieve the effects of less cooling time, short unlocking time and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

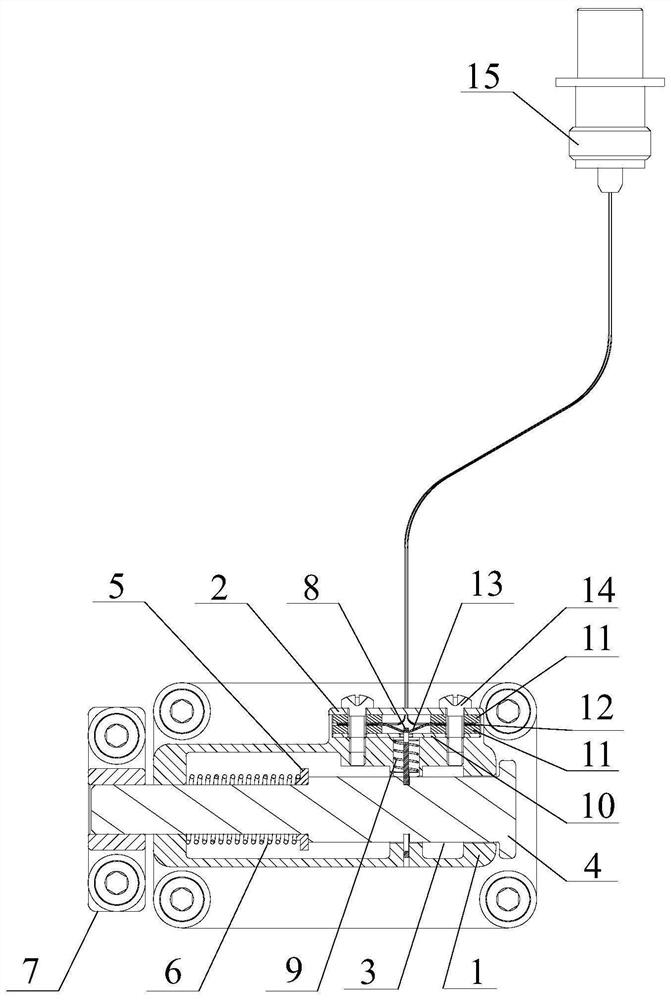

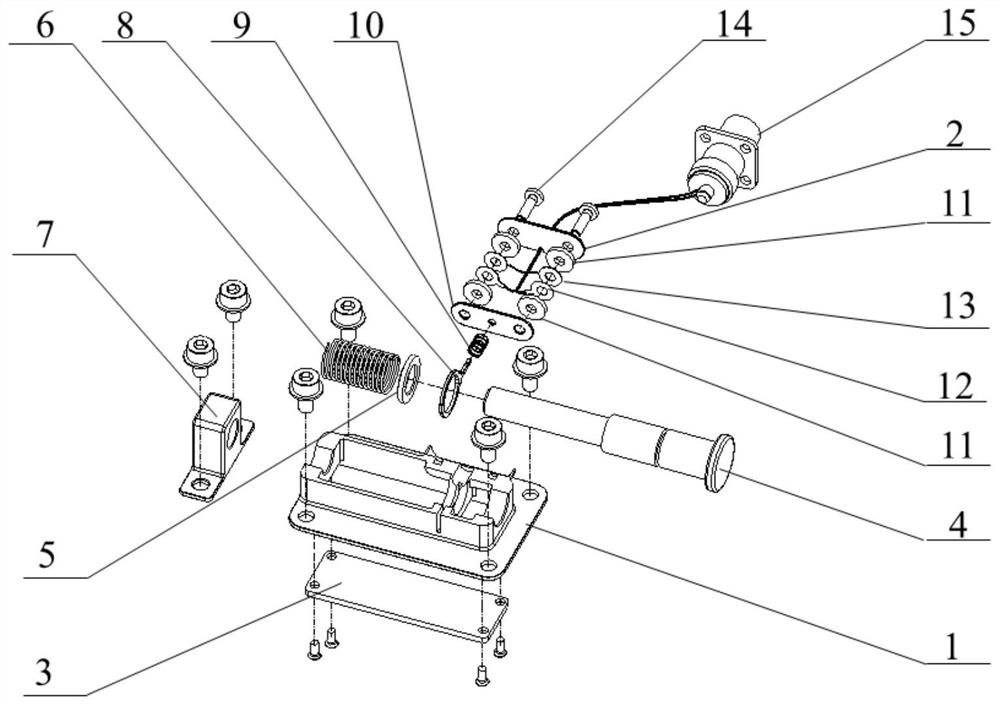

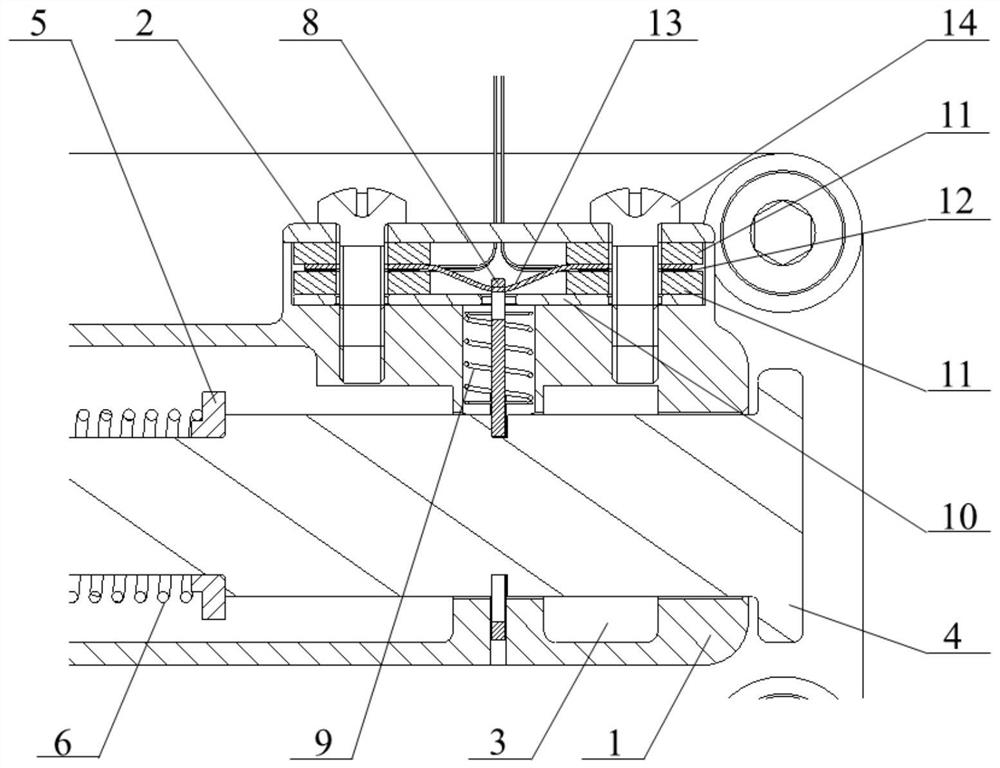

[0030] The present invention will be further described below in conjunction with accompanying drawing.

[0031] A split memory alloy spring pin, such as Figure 1-4 As shown, it includes mounting seat 1, side cover 2, bottom cover 3, pin 4, retaining ring 5, pin spring 6, pin hole seat 7, locking plate 8, locking spring 9, pressure plate 10, and insulation pad 11 , heating sheet 12, memory alloy sheet 13 and electrical connector 15, the side cover 2 is installed on the side of the mounting seat 1, and the bottom cover 3 is installed at the bottom;

[0032] The pin 4 passes through the round hole on the right wall of the mounting seat 1, the round hole in the middle rib, the locking plate 8, the retaining ring 5, the pin spring 6 and the round hole on the left side wall of the mounting seat 1 in sequence from the right, and finally inserts it into the pin hole seat 7 the pin hole;

[0033] One end of the locking piece 8 is a ring, the other end is a slender strip, the end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com