Vertical variable shear force type direct shear creepmeter

A creep meter, vertical technology, applied in the field of geotechnical laboratory test, can solve the problem that the shear stress cannot be kept constant, the loss of axial pressure, etc., to achieve the effect of ensuring the shear stress, reducing the shear force, and ensuring constant and constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following are merely examples of implementation of the present invention, and should not limit the scope of the present invention. That is to say, all non-substantial changes and modifications made according to the patent scope of the present invention should still fall within the scope covered by the patent of the present invention.

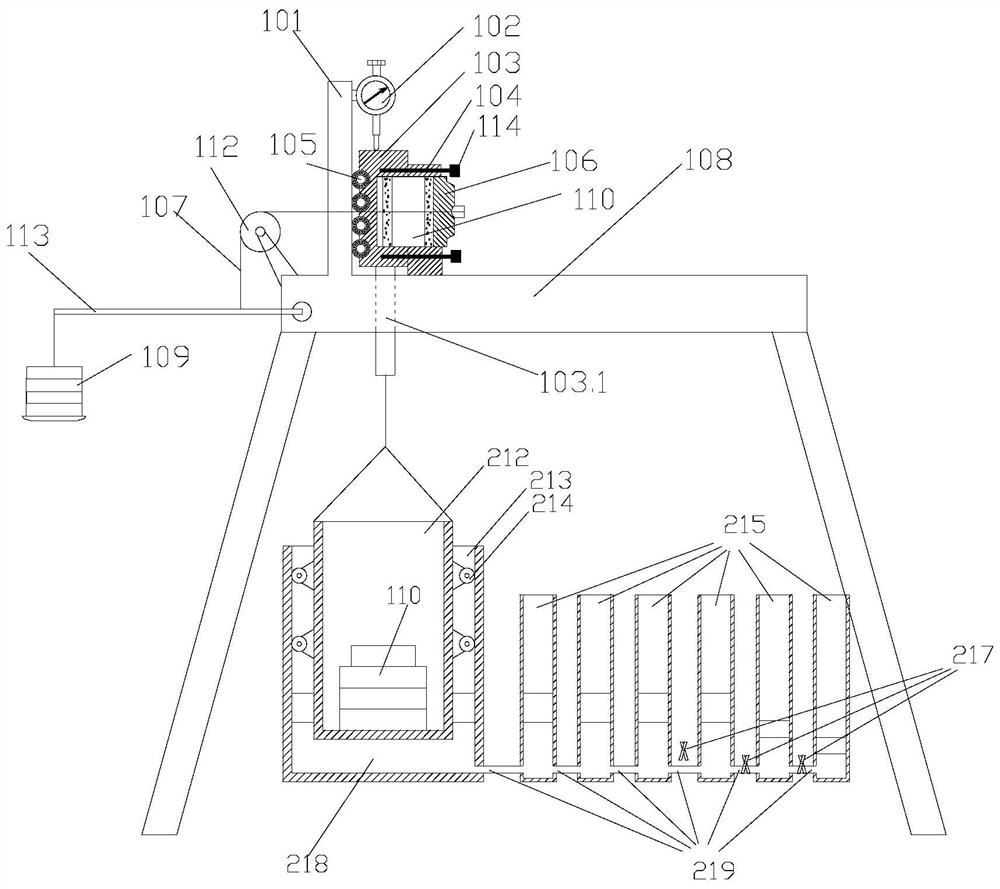

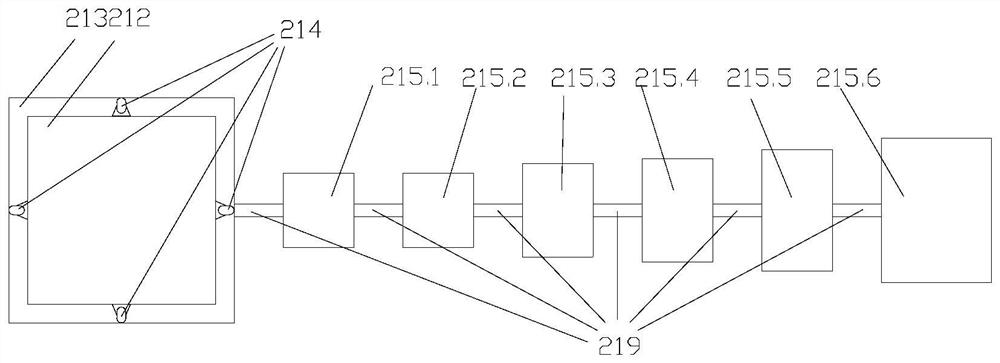

[0032] Such as figure 1 Shown is the vertical variable shear type direct shear creep meter of the present invention, which includes an instrument table 108, a shear box, a dial gauge 102 and a pressurization system.

[0033] An upright baffle 101 is provided on the instrument table 108 table, and the position of the table near the upright baffle has a perforation that runs through up and down. The instrument table table is supported by four legs, keeps level, and is perpendicular to the described upright baffle. The dial of the dial indicator 102 is fixed on the upright baffle, and the spring contact head of the dial indicator is in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com