Modular bionic wall-climbing robot

A wall-climbing robot and modular technology, which is applied in the directions of motor vehicles, transportation and packaging, can solve the problems of low adhesion and the inability of wall-climbing robots to adapt to different working environments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

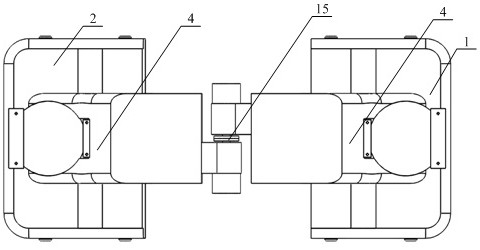

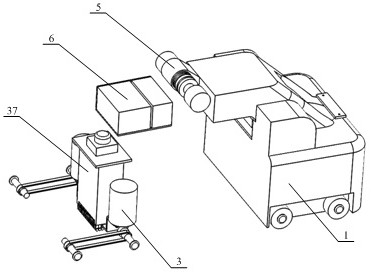

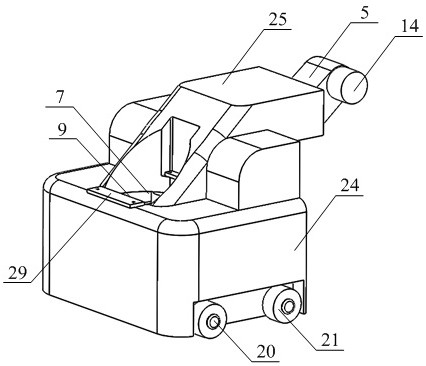

[0029] Such as figure 1 , 2 , 3, and 5, the present invention comprises two identical parts (1), (2) before and after the robot. Each part includes a traveling mechanism (3), a car body structure (4), a pitching mechanism (5), a power supply and control assembly (6), a quick-change interface assembly (7) and a vacuum adsorption device (37).

[0030] The locking mechanism (9) on the car body structure (4) includes the stop shoulder (28) and the corresponding fixed pressure plate (29) on the main structure (24), through the stop shoulder (28) and the fixed pressure plate ( 29) Cooperate with each other to compress and fix the corresponding structure on the quick change module to the main structure (24). When the front and rear parts (1) and (2) of the modular bionic wall-climbing robot and the quick-change module are installed, the front and rear parts (1) and (2) of the robot pass through the corresponding pitch output flanges (15) connected.

[0031] Such as Figure 10As ...

Embodiment 2

[0034] Such as Figure 4 , 6 , 7, the vacuum adsorption device (37) includes a vacuum generator (38), a vacuum adsorption fixing plate (39) and a vacuum curtain assembly (40), and the vacuum generator (38) and the vacuum curtain assembly (40 ) is fixed on the vacuum adsorption fixing plate (39) by screws, and connected with the vehicle body main structure (24) through the vacuum adsorption fixing plate (39); the vacuum curtain assembly (40) consists of a vacuum fixing frame (41), Composed of a forward curtain (31) and a side curtain (32), the forward curtain (31) is composed of a plurality of deflection rods (34), through the rotating shaft (33) on the vacuum fixing frame (41) ) is connected with the vacuum fixed frame (41) and swings around the rotation axis (33). The side curtain (32) is composed of a plurality of telescopic rods (35), passing through the telescopic holes on the vacuum fixed frame (41) Realize the up and down movement of telescopic rod (35).

[0035] When...

Embodiment 3

[0040] Such as Figure 5 As shown, the quick-change module and the robot are quickly connected and replaced through the quick-change interface assembly (7). The stop shoulders (28) on 24) cooperate with each other to be inserted horizontally, and the data interface (26) and the power supply interface (27) in the power supply interface assembly (10) are naturally docked with each other during the insertion process. After the insertion is completed, the fixed pressure plate (29) in the locking mechanism (9) is fixed on the main structure (24) by bolts, and the quick connection between the quick change module and the robot is realized from the two aspects of structure and electric control through the above method.

[0041] Working principle of the present invention is:

[0042] Such as Figure 8 , 9 As shown, the traveling mechanism (3) includes a traveling drive motor (8), a traveling motor fixing plate (16), a bevel gear set (17), a synchronous belt (18), two synchronous pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com