Transformer transfer device

A transfer device and transformer technology, applied in the direction of unloading device, transportation and packaging, containers, etc., can solve the problems of easy damage to the transformer, easy to cause accidents, troublesome transfer process, etc., and achieve the effect of avoiding shaking and preventing back and forth shaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

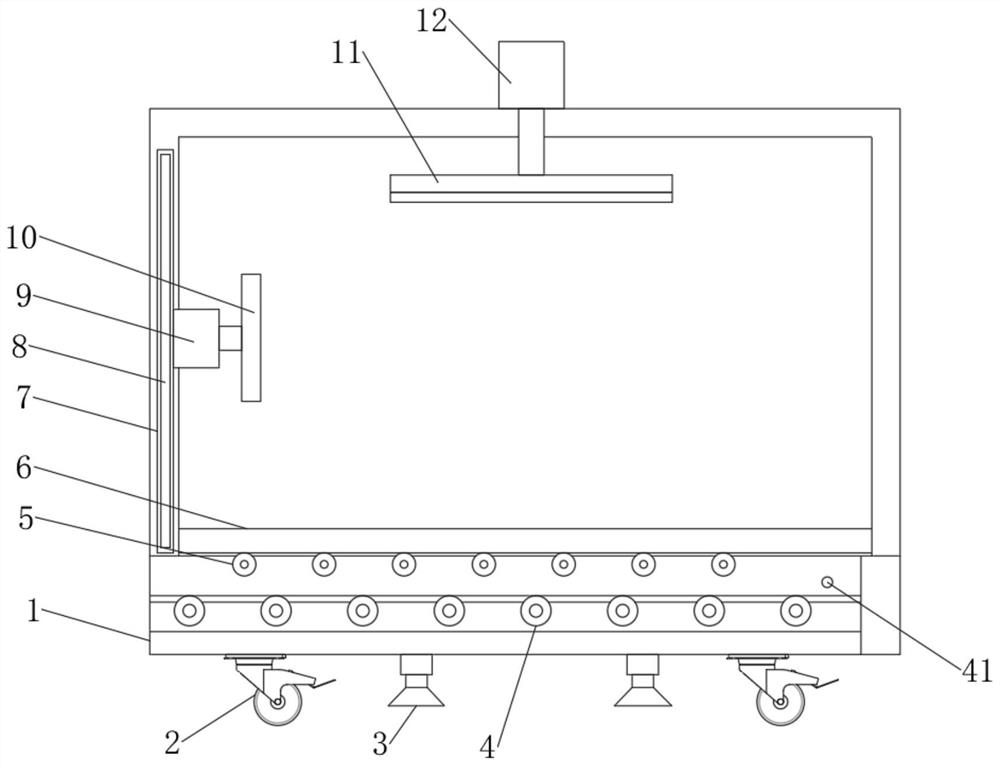

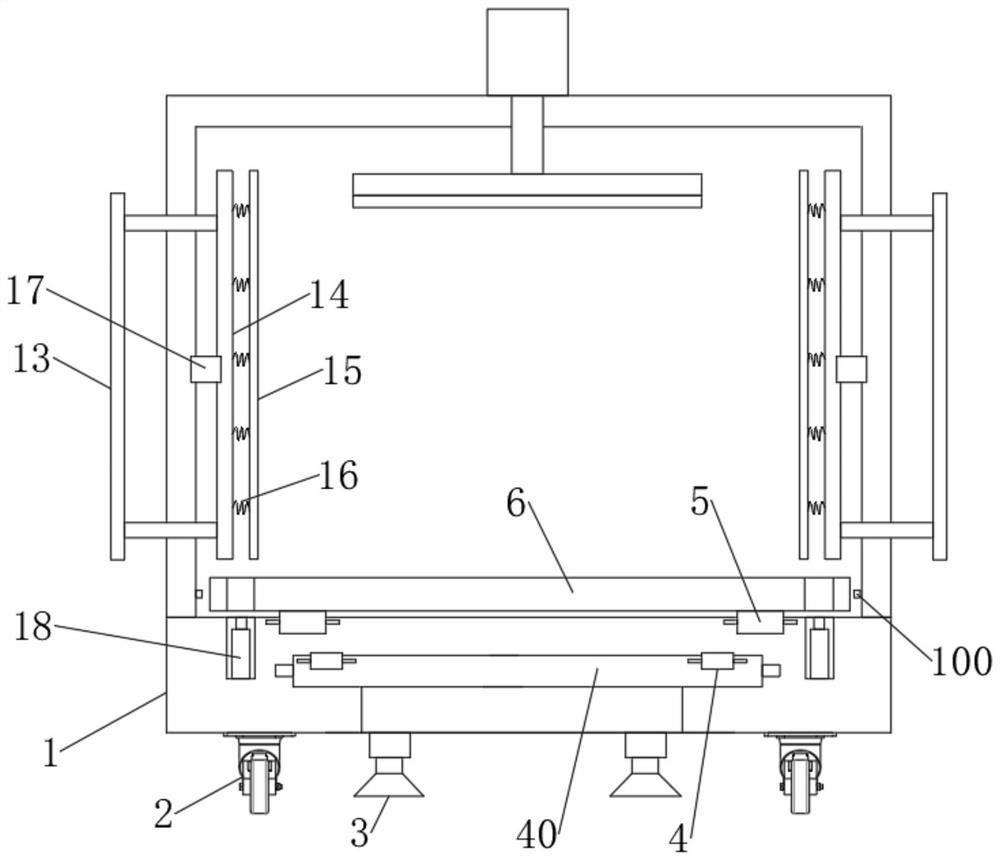

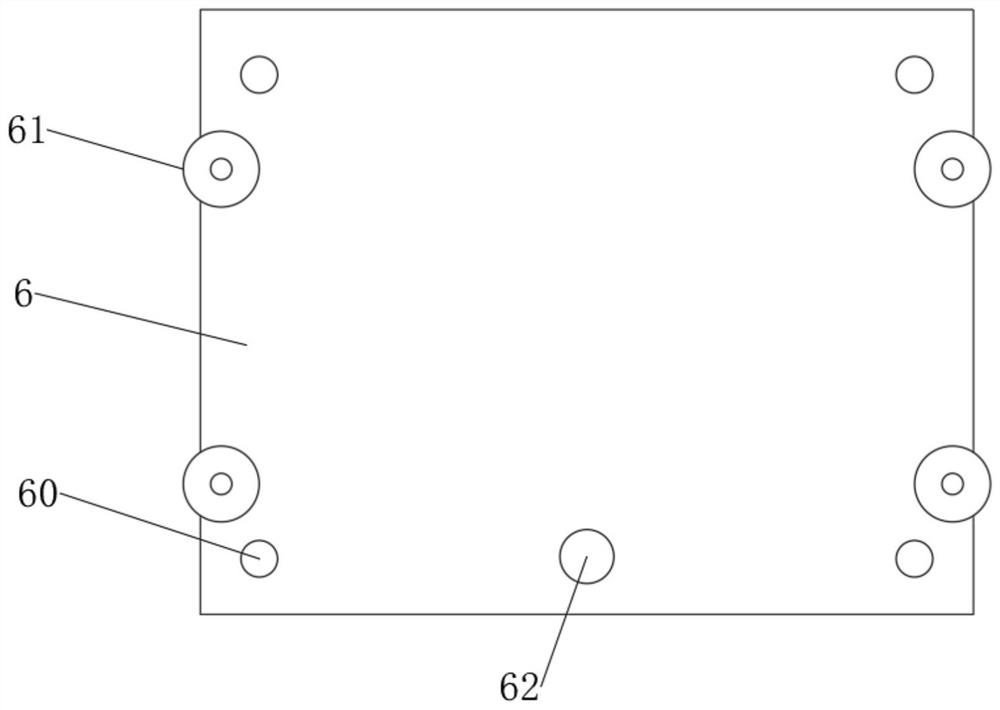

[0030] Such as Figure 1-6 As shown, a transformer transfer device includes a housing 1, the bottom of the housing 1 is provided with a universal wheel 2, the bottom of the housing 1 is provided with an inner panel 40, and the two ends of the inner panel 40 A sliding column 41 is provided, and a chute 42 is provided on the housing 1. The inner panel 40 is slidably connected to the chute 42 through the sliding column 41. The chute 42 is set in a J shape, and the inner panel 40 The bottom of 40 is provided with a hydraulic seat 3, the surface of the inner panel 40 is provided with a first roller 4, the surface of the bottom of the housing 1 is provided with a second roller 5, and a placement plate is arranged on the second roller 5 6. The placement plate 6 is provided with a fixing hole 60, the bottom plate of the housing 1 is embedded with a telescopic column 18, and the telescopic column 18 is fixedly installed with the bottom of the housing 1, and the telescopic column 18 is ...

Embodiment 2

[0039] This embodiment is a further improvement and limitation of embodiment 1 on the basis of embodiment 1.

[0040] A transformer transfer device, including all parts in embodiment 1, also includes:

[0041] Further, a first hydraulic cylinder 9 is movably installed on the front cover plate 8, the first hydraulic cylinder 9 is connected to the first fixing plate 10, and the top of the housing 1 is provided with a second hydraulic cylinder 12, The second hydraulic cylinder 12 is connected with the second fixing plate 11 .

[0042]Specifically, the first hydraulic cylinder 9 is installed through the front cover plate 8, the front end of the transformer is fixed by the first hydraulic cylinder 9 and the first fixing plate 10, and the top of the transformer is fixed by the second hydraulic cylinder 12 and the second fixing rod. fixed.

[0043] Further, the left and right sides of the housing 1 are provided with mounting brackets 13, the mounting brackets 13 are plugged into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com