Oxygen sensor calibration method and steaming and baking equipment applying same and capable of accurately detecting humidity

A technology of oxygen sensor and calibration method, which is applied in applications, roasters/barbecue grids, instruments, etc., can solve problems such as poor consistency of test results and affect the performance of steaming and roasting equipment, and achieve good cooking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

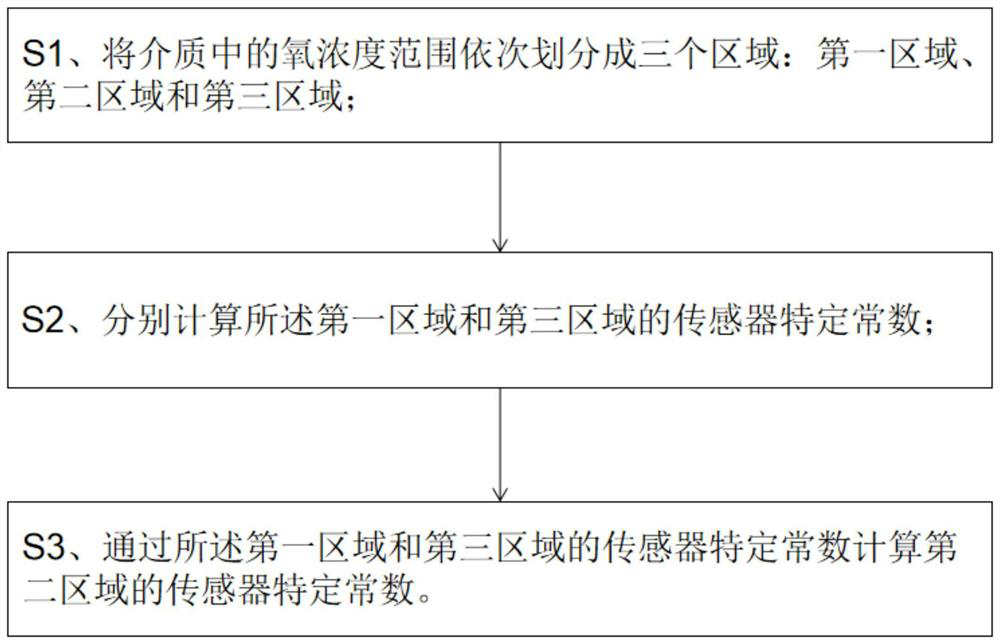

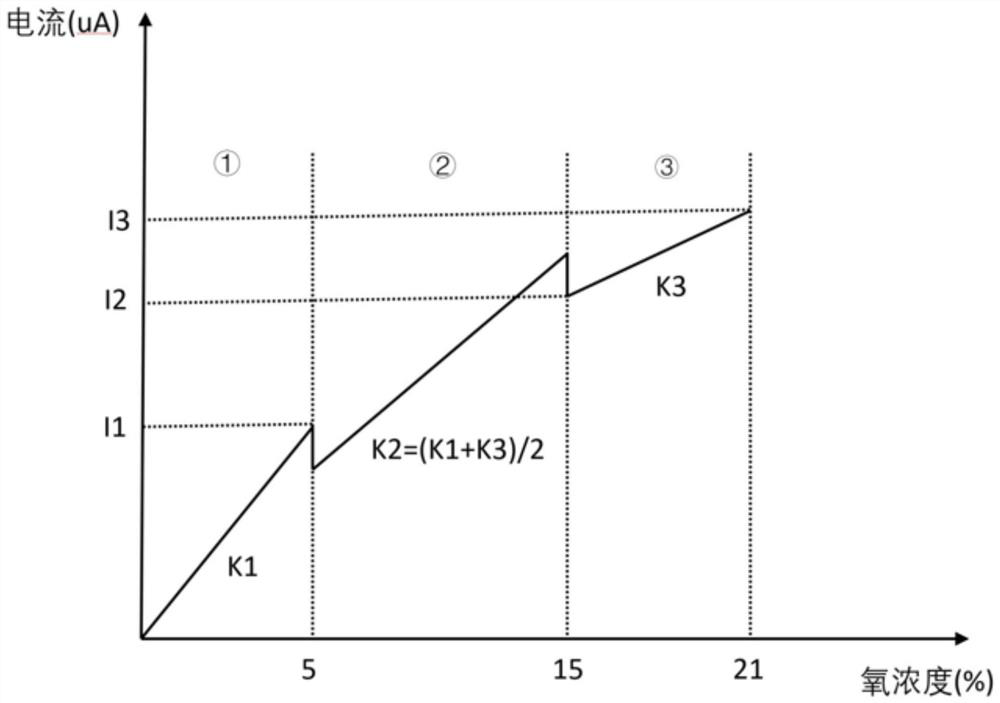

[0049] Embodiment 1 of the present invention provides an oxygen sensor calibration method, such as Figure 1-3 shown, including the following steps:

[0050] S1. Divide the oxygen concentration range in the medium into three areas in turn: the first area, the second area and the third area;

[0051] S2. Calculate specific constants of the oxygen sensors in the first area and the third area, respectively;

[0052] S3. Calculating the specific constants of the oxygen sensors in the second area based on the specific constants of the oxygen sensors in the first area and the third area, so as to calibrate the specific constants of the oxygen sensors in different oxygen concentration ranges.

[0053] In this way, by dividing the oxygen concentration range in the medium into three regions: the first region, the second region and the third region, and then calculating the oxygen sensor temperature of the first region and the third region respectively according to the current value an...

Embodiment 2

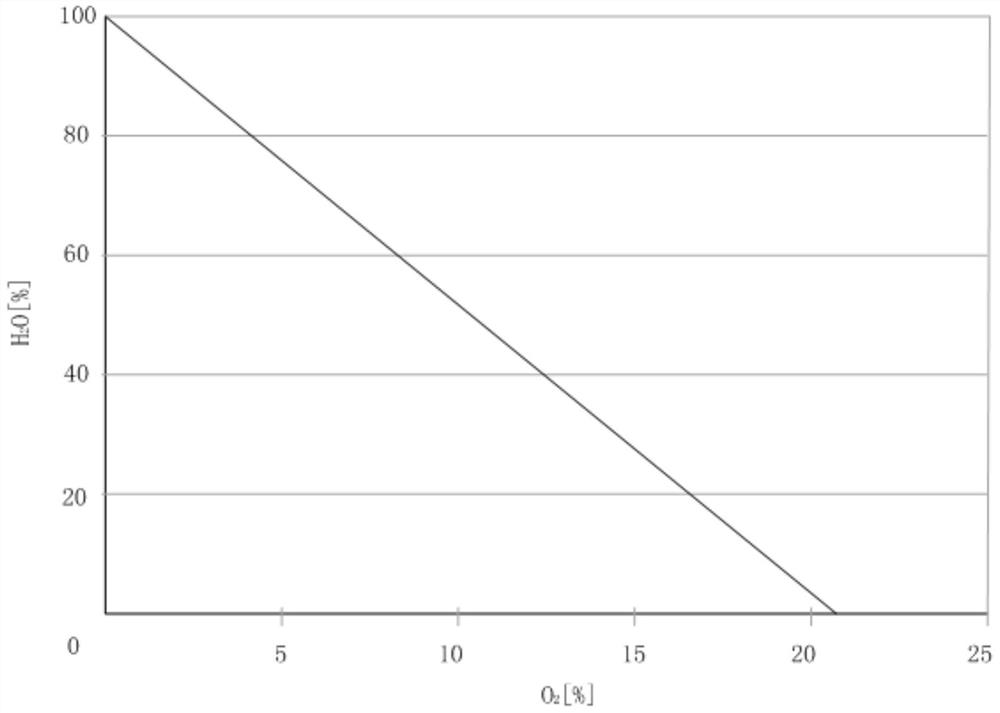

[0086] Such as Figure 4-5 As shown, Embodiment 2 of the present invention provides a steaming and roasting device for accurately detecting humidity using the oxygen sensor calibration method, including a steaming and roasting device body 1, an evaporator 2, a water tank 3, a temperature sensor 4 and an oxygen sensor 5, The water tank 3 is connected to the evaporator 2 through a water pump and a water pipe, and the evaporator 2 is connected to the steaming equipment body 1 through a steam pipeline, and a temperature sensor 4 and an oxygen sensor 5 are installed in the steaming equipment body 1;

[0087] According to the oxygen concentration range of the oxygen sensor 5, the steaming equipment body 1 is divided into three modes in sequence from low to high:

[0088] The first zone is a pure steam mode, and the specific constant of the oxygen sensor is the specific constant of the oxygen sensor in the first zone;

[0089] The second area is tender roast mode, and the specific c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com