Large-inertia grinding head motor

A technology with large inertia and grinding head, which is applied to the parts of grinding machine tools, machine tools suitable for grinding workpiece edges, grinding machines, etc. It can solve the problems of different inertia of motors and waste of torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

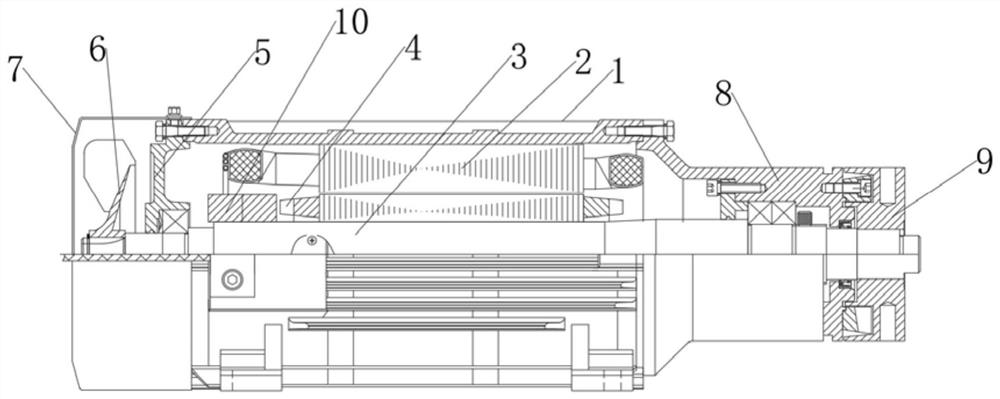

[0009] Depend on figure 1 As shown, the large inertia grinding head motor of the present invention includes a housing 1 , a stator core 2 with windings disposed in the housing 1 , and a rotor 4 located in the stator core 2 and supported by a motor shaft 3 . The front and rear ends of the housing 1 are connected with a front end cover 8 and a rear end cover 5, and the front end and the rear end of the motor shaft 3 pass through the front end cover 8 and the rear end cover 5 respectively and are respectively fixed with a grinding wheel seat 10 and a fan. 6. The wind cover 7 covering the fan 6 is also fixed on the rear end cover 5 . A plurality of inertia rings are arranged on the rear end of the motor rotating shaft, and the inertia rings are fixed on the motor rotating shaft by shrink-fit interference fit, and the front end of the inertia ring is close to the rear end of the iron core of the rotor.

[0010] When in use, according to the design principle of the motor, under dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com