Push type cleaning solution bottle

A cleaning liquid, pressing technology, applied in the direction of containers, packaging, transportation and packaging with multiple items, which can solve problems such as easy pressing by mistake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

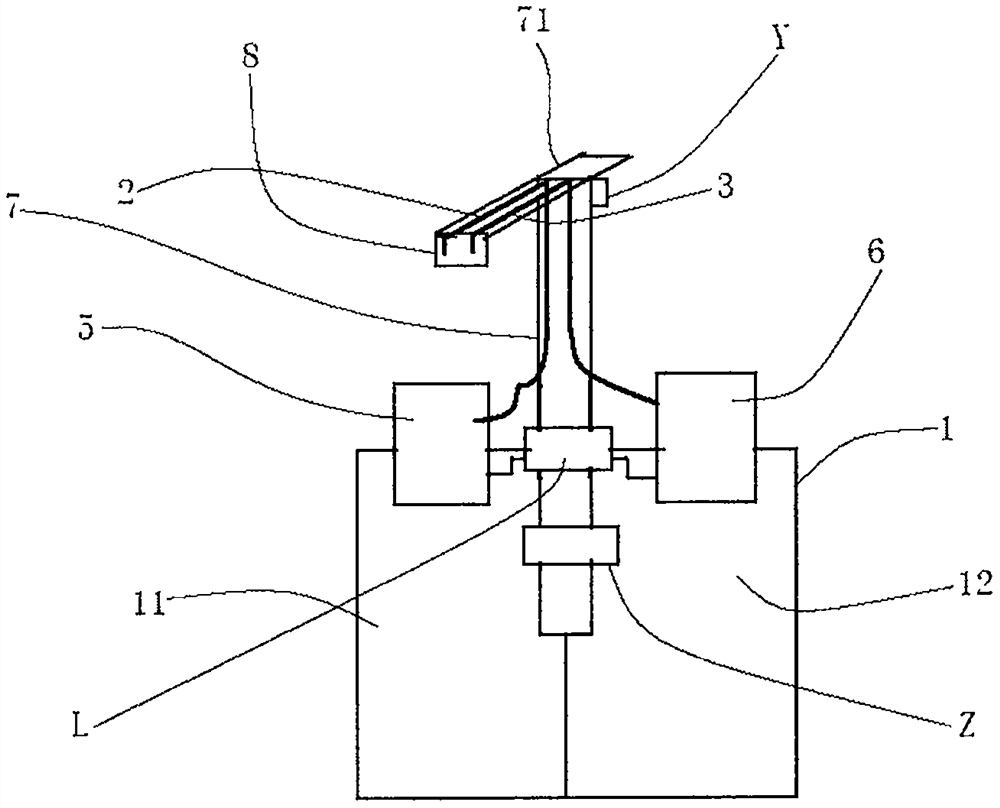

[0033]A push-type cleaning liquid bottle, including a housing 1, a first infusion tube 2, a second infusion tube 3, a first press liquid outlet structure 5, a second press liquid outlet structure 6, a slider 7, and a liquid outlet nozzle 8 The housing 1 is provided with a first chamber 11 and a second chamber 12; the first pressing liquid outlet structure 5 is arranged on the first chamber 11, and the tail end of the first infusion tube 2 is connected to the first pressing liquid outlet structure 5 , the first end of the first infusion tube 2 is connected to the liquid outlet nozzle 8, so that the liquid from the first chamber 11 pressed by the first pressing liquid outlet structure 5 can flow out of the liquid outlet nozzle 8; the second pressing liquid outlet structure 6 is set On the second chamber 12, the tail end of the second infusion tube 3 is connected to the second pressing liquid outlet structure 6, and the head end of the second infusion tube 3 is connected to the li...

Embodiment 2

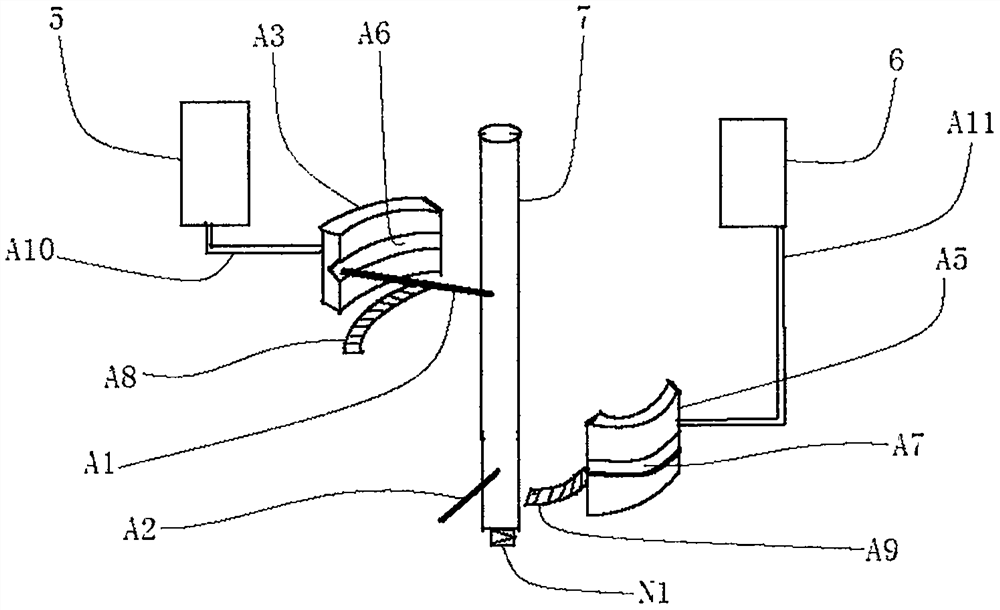

[0040] A push-type cleaning liquid bottle, including a housing 1, a first infusion tube 2, a second infusion tube 3, a first press liquid outlet structure 5, a second press liquid outlet structure 6, a slider 7, and a liquid outlet nozzle 8 The housing 1 is provided with a first chamber 11 and a second chamber 12; the first pressing liquid outlet structure 5 is arranged on the first chamber 11, and the tail end of the first infusion tube 2 is connected to the first pressing liquid outlet structure 5 , the first end of the first infusion tube 2 is connected to the liquid outlet nozzle 8, so that the liquid from the first chamber 11 pressed by the first pressing liquid outlet structure 5 can flow out of the liquid outlet nozzle 8; the second pressing liquid outlet structure 6 is set On the second chamber 12, the tail end of the second infusion tube 3 is connected to the second pressing liquid outlet structure 6, and the head end of the second infusion tube 3 is connected to the l...

Embodiment 3

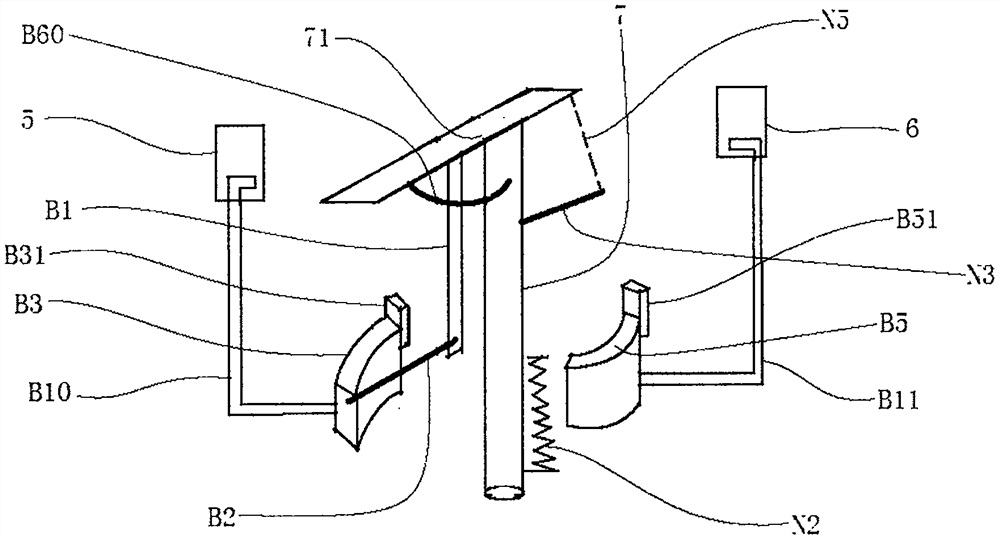

[0047]A push-type cleaning liquid bottle, including a housing 1, a first infusion tube 2, a second infusion tube 3, a first press liquid outlet structure 5, a second press liquid outlet structure 6, a slider 7, and a liquid outlet nozzle 8 The housing 1 is provided with a first chamber 11 and a second chamber 12; the first pressing liquid outlet structure 5 is arranged on the first chamber 11, and the tail end of the first infusion tube 2 is connected to the first pressing liquid outlet structure 5 , the first end of the first infusion tube 2 is connected to the liquid outlet nozzle 8, so that the liquid from the first chamber 11 pressed by the first pressing liquid outlet structure 5 can flow out of the liquid outlet nozzle 8; the second pressing liquid outlet structure 6 is set On the second chamber 12, the tail end of the second infusion tube 3 is connected to the second pressing liquid outlet structure 6, and the head end of the second infusion tube 3 is connected to the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com