Strontium magnesium niobate doped modified sodium bismuth titanate-based energy storage ceramic material and preparation method thereof

A technology based on sodium bismuth titanate and strontium magnesium niobate, which is applied in the field of ceramic capacitor materials, can solve the problems of low breakdown field strength and small polarization difference, and achieves the effects of low cost, large output, and a green preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing a bismuth sodium titanate-based energy storage ceramic material doped with strontium niobate magnesium oxide, which comprises the following steps:

[0031] (1) Weigh Bi according to the ratio of the stoichiometric formula 2 o 3 、Na 2 CO 3 、TiO 2 , SrCO 3 , MgO and Nb 2 o 5 Mix, and follow the principle of "a large amount - a small amount - a large amount"; then carry out ball milling, the process of ball milling can refine the powder, and at the same time make the mixing of various materials more uniform. Among them, ball milling takes 8 to 12 hours, and the speed of ball milling is 330 to 400 r / min. After ball milling, dry the mixture at 85-100°C for 2-4 hours; sieve through a 60-120 mesh sieve to obtain the general formula of chemical composition (1-x)(Bi 0.5 Na 0.5 )TiO 3 -xSr(Mg 0.3334 Nb 0.6666 )O 3 Powder, said 0≦x≦0.20.

[0032] (2) Add the above-mentioned mixture into the crucible, after compaction, put...

Embodiment 1

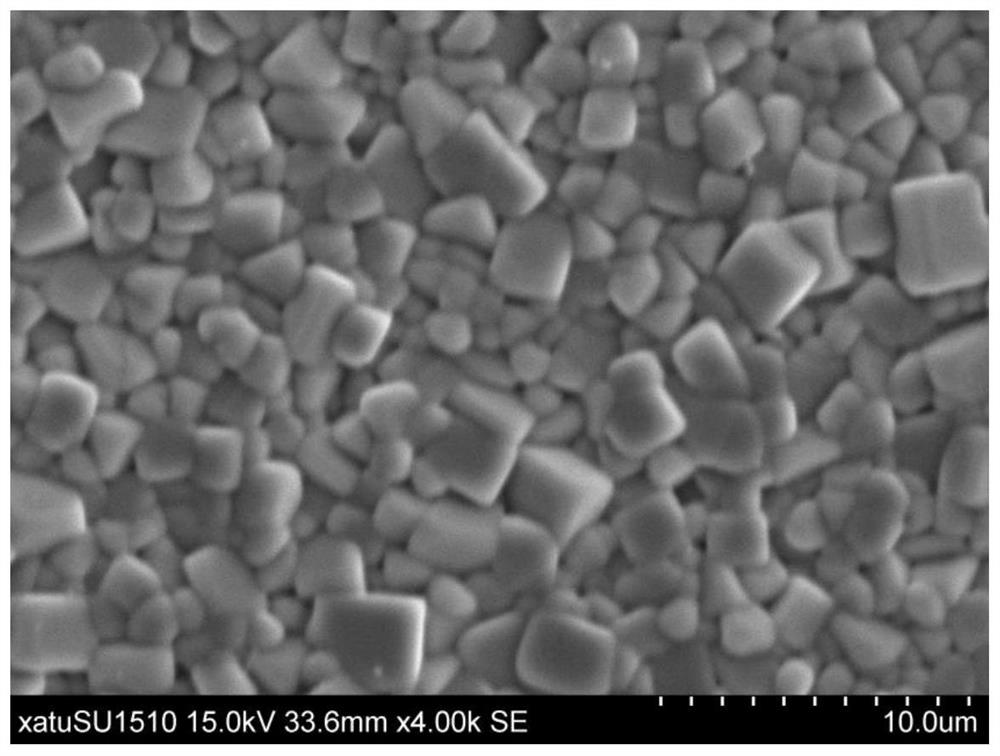

[0037] In this example, strontium niobate magnesium doped modified bismuth sodium titanate based energy storage ceramics has a chemical composition of 0.90 (Bi 0.5 Na 0.5 )TiO 3 -0.10Sr(Mg 0.3334 Nb 0.6666 )O 3 , the steps of its preparation method include:

[0038] (1) Weigh Bi according to the ratio of the stoichiometric formula 2 o 3 、Na 2 CO 3 、TiO 2 , SrCO 3 , MgO and Nb 2 o 5 Mix, and follow the principle of "a large amount - a small amount - a large amount"; then perform ball milling, wherein the ball milling time is 12 hours, and the rotational speed of the ball milling is 350r / min. After ball milling, the mixture was dried at 85°C for 2 hours; sieved with a 60-mesh sieve to obtain 0.90 (Bi 0.5 Na 0.5 )TiO 3 -0.10Sr(Mg 0.3334 Nb 0.6666 )O 3 Powder.

[0039] (2) Add the above mixture into the crucible, place it in a sintering furnace, raise the temperature to 850°C and keep it warm for 2h, the heating rate of pre-firing is 3°C / min, and then cool down ...

Embodiment 2

[0046] According to the formula (1-x) (Bi 0.5 Na 0.5 )TiO 3 -xSr(Mg 0.3334 Nb 0.6666 )O 3 , except that the value of x is changed, other steps are the same as in Example 1. Calculate the required amount of each raw material, and weigh it with an electronic balance, and the weighing is accurate to 3 decimal places.

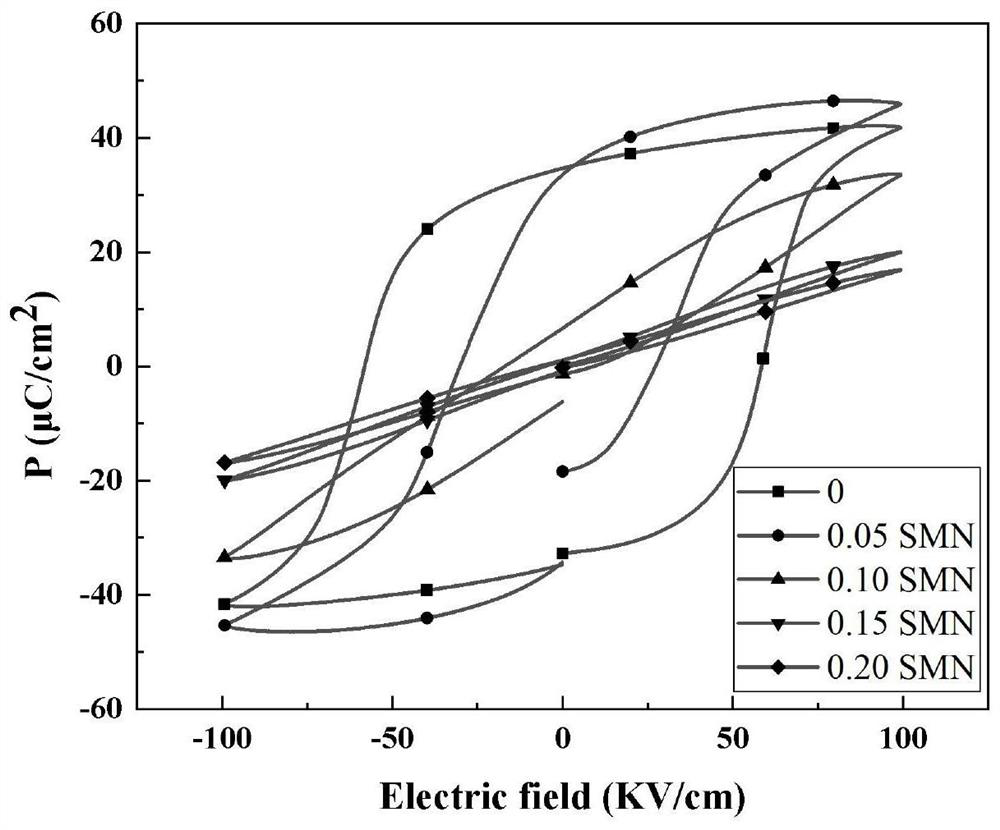

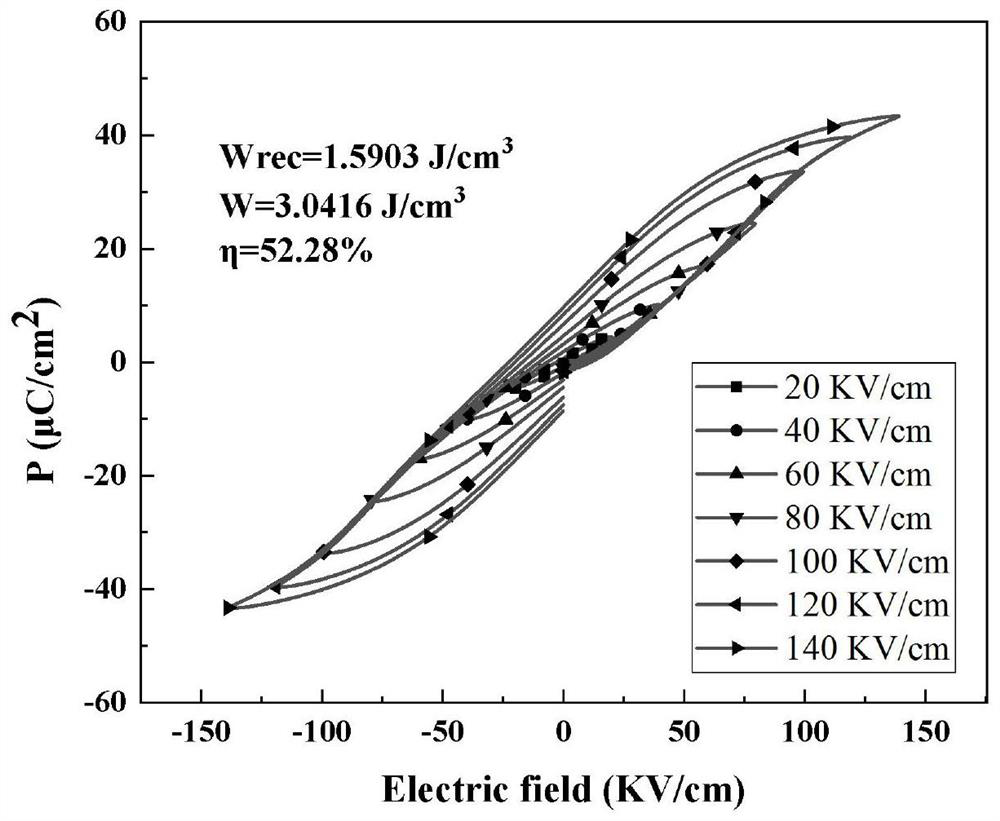

[0047] The hysteresis loop tests of different electric field strengths at room temperature were carried out on the energy storage ceramic samples prepared in Example 2, as shown in figure 2 As shown, with the increase of the doping amount of strontium magnesium niobate, the recyclable energy storage density shows a trend of first increasing and then decreasing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breakdown field strength | aaaaa | aaaaa |

| Energy storage density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com