A kind of composite ceramic material and preparation method thereof

A technology of composite ceramics and ball milling, which is applied to fixed capacitor parts, fixed capacitors, fixed capacitor dielectrics, etc., can solve the problems of not being high enough and difficult to combine, so as to improve the breakdown electric field, facilitate implementation, and increase energy storage effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] For the preparation method of the composite ceramic material, the following preparation steps are included:

[0038] Step 1, separate Bi 2 O 3 , Na 2 CO 3 , SrCO 3 , TiO 2 According to the chemical formula 0.5 (Bi 0.5 Na 0.5 )TiO 3 -0.5(Sr 0.7 Bi 0.2 )TiO 3 Carry out batching, the mixture obtained by batching is ball-milled and mixed under anhydrous ethanol medium to obtain slurry, and then the slurry is put into an oven and dried at 80 ° C, and finally 0.5 (Bi) is formed. 0.5 Na 0.5 )TiO 3 -0.5(Sr 0.7 Bi 0.2 )TiO 3 powder;

[0039] In step 2, the 0.5 (Bi 0.5 Na 0.5 )TiO 3 -0.5(Sr 0.7 Bi 0.2 )TiO 3 The powder is put into a crucible and pre-fired in an air atmosphere. Specifically, 0.5 (Bi 0.5 Na 0.5 )TiO 3 -0.5(Sr 0.7 Bi 0.2 )TiO 3 The powder is burned in air at 850℃ for 3 hours;

[0040] Step 3, put 0.5 (Bi 0.5 Na 0.5 )TiO 3 -0.5(Sr 0.7 Bi 0.2 )TiO 3 The pre-fired powder is granulated and sieved, then put into a crucible, and subjecte...

specific Embodiment 1

[0043] This example is for the preparation of single-phase 0.5 (Bi 0.5 Na 0.5 )TiO 3 -0.5(Sr 0.7 Bi 0.2 )TiO 3 Ceramic material, including the following steps:

[0044] (1) Using Bi 2 O 3 , Na 2 CO 3 , SrCO 3 , TiO 2 As the raw material, according to the chemical formula 0.5 (Bi 0.5 Na 0.5 )TiO 3 -0.5(Sr 0.7 Bi 0.2 )TiO 3 make ingredients;

[0045] (2) Using absolute ethanol as a medium, the mixture obtained in the previous step was ball-milled for 24 hours and dried at 80°C;

[0046] (3) pre-calcining the dried mixture powder, specifically, calcining the mixture powder in the air at 850 ° C for 3 hours, the temperature rise and fall rate is 3.5 ° C / min, to obtain 0.5 (Bi 0.5 Na 0.5 )TiO 3 -0.5(Sr 0.7 Bi 0.2 )TiO 3 Pre-fired powder;

[0047] (4) Set 0.5 (Bi 0.5 Na 0.5 )TiO 3 -0.5(Sr 0.7 Bi 0.2 )TiO 3 After the calcined powder is dried, granulation, tableting and sintering are carried out. Specifically, PVA was added as a binder for granulation an...

specific Embodiment 2

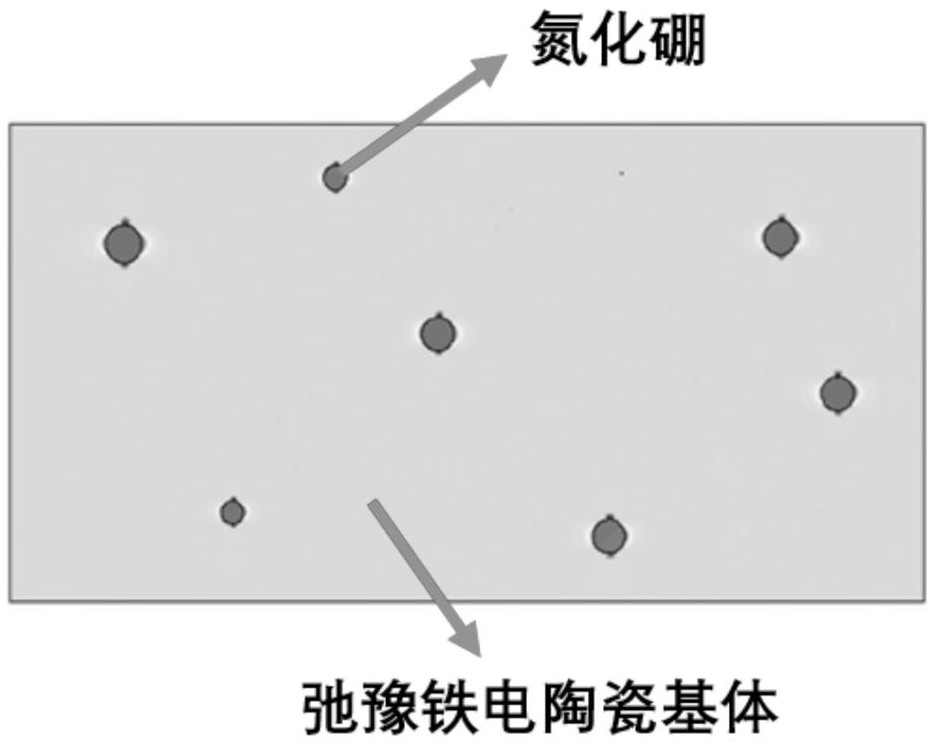

[0048] This example is to prepare 0.5 (Bi 0.5Na 0.5 )TiO 3 -0.5(Sr 0.7 Bi 0.2 )TiO 3 / BN composite ceramic material, including the following steps:

[0049] (1) Using Bi 2 O 3 , Na 2 CO 3 , SrCO 3 , TiO 2 As the raw material, according to the chemical formula 0.5 (Bi 0.5 Na 0.5 )TiO 3 -0.5(Sr 0.7 Bi 0.2 )TiO 3 make ingredients;

[0050] (2) Using absolute ethanol as a medium, the mixture obtained in the previous step was ball-milled for 24 hours and dried at 80°C;

[0051] (3) pre-calcining the dried mixture powder, specifically, calcining the mixture powder in air at 850° C. for 3 hours to obtain 0.5 (Bi 0.5 Na 0.5 )TiO 3 -0.5(Sr 0.7 Bi 0.2 )TiO 3 Pre-fired powder;

[0052] (4) to 0.5 (Bi 0.5 Na 0.5 )TiO 3 -0.5(Sr 0.7 Bi 0.2 )TiO 3 The calcined powder is subjected to high temperature heat treatment. Specifically, at 0.5 (Bi 0.5 Na 0.5 )TiO 3 -0.5(Sr 0.7 Bi 0.2 )TiO 3 8wt% polyvinyl alcohol solution (concentration of 5%) was added to the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com