A kind of trace zirconium dioxide added st-nbt energy storage ceramic and preparation method thereof

A zirconium dioxide and energy storage technology is applied in the field of adding trace zirconium dioxide to ST-NBT energy storage ceramics and its preparation, which can solve the problems such as the energy storage density is not significantly improved, and achieves low cost, simple preparation process, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A preparation method for adding ST-NBT energy storage ceramics with a trace amount of zirconia, comprising the following steps:

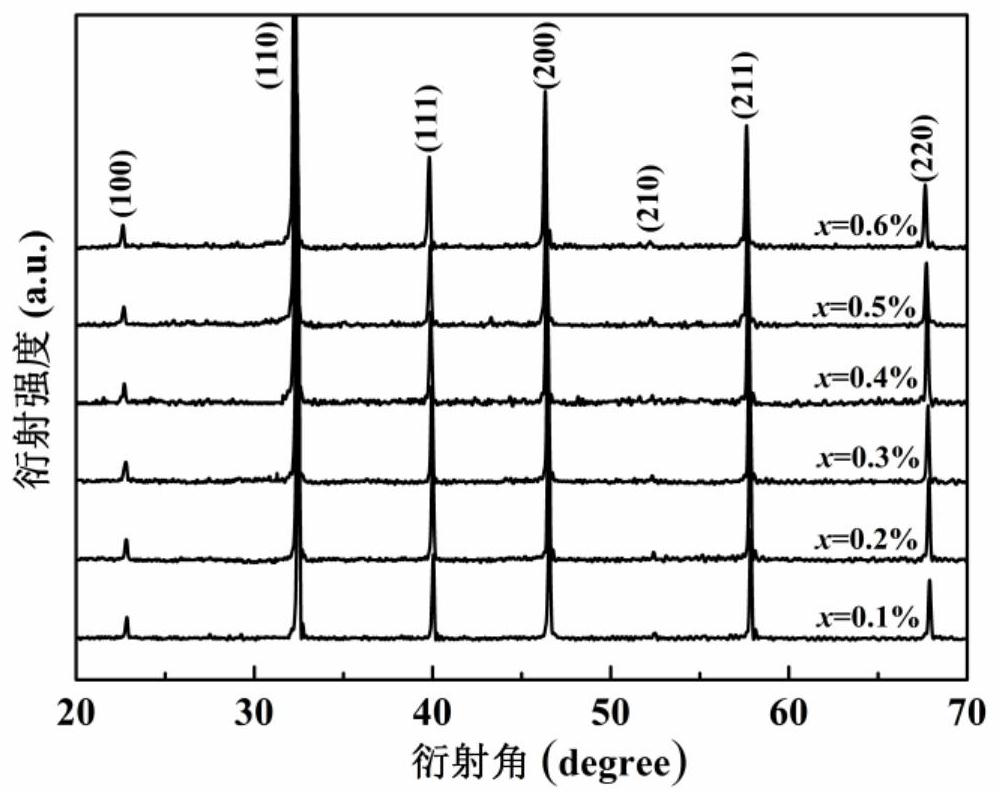

[0030] Step 1: According to the stoichiometric formula (1-x) (0.6SrTiO 3 -0.4Na 0.5 Bi 0.5 TiO 3 )-xZrO 2 , x=0.1~0.6mol%, take SrTiO 3 Powder, Na 0.5 Bi 0.5 TiO 3 Powder and ZrO 2 The powder is mixed evenly to form a complete ingredient, SrTiO 3 The preparation steps of the powder include: first weigh the SrCO2 according to the molar ratio of 1:1 3 and TiO 2 Mix to form mixture A; then take mixture A, zirconium balls and deionized water, mix them according to the mass ratio of 1:2:(0.8~1.5), then perform ball milling, drying and briquetting in sequence, and finally keep warm at 1150~1180℃ 3 to 4 hours to obtain pure phase SrTiO 3 Powder; Na 0.5 Bi 0.5 TiO 3 The preparation steps of the powder include: first weigh Bi according to the molar ratio of 1:1:4 2 o 3 、Na 2 CO 3 and TiO 2 Mix to form mixture B; then take mixture B...

Embodiment 1

[0036] In this example ZrO 2 Add 0.6SrTiO 3 -0.4Na 0.5 Bi 0.5 TiO 3 Energy storage ceramics whose formula is (1-x)(0.6SrTiO 3 -0.4Na 0.5 Bi 0.5 TiO 3 )-xZrO 2 , where x=0.1 mol%.

[0037] Step 1: Preparation of pure phase SrTiO 3 and pure phase Na 0.5 Bi 0.5 TiO 3 spare. Weigh SrCO according to the molar ratio of 1:1 3 and TiO 2 Mix to form mixture A; weigh Bi according to the molar ratio 1:1:4 2 o 3 , Na 2 CO 3 and TiO 2 Mix to form Mixture B. SrCO 3 , Bi 2 o 3 , Na 2 CO 3 and TiO 2 The purity is above 99.0%.

[0038] Step 2: Mix the mixtures A and B with zirconium balls and deionized water respectively according to the mass ratio of 1:2:0.8 and 1:2:1, then use a planetary ball mill for 18 hours, and then dry at 85°C for 26 hours 1. After briquetting, put them in a box-type furnace for 4 hours at 1150° C. and 4.5 hours at 840° C. to form mixtures A and B presynthetic materials respectively for later use.

[0039] Step 3: pre-synthesizing material ...

Embodiment 2

[0045] In this example ZrO 2 Add 0.6SrTiO 3 -0.4Na 0.5 Bi 0.5 TiO 3 Energy storage ceramics whose formula is (1-x)(0.6SrTiO 3 -0.4Na 0.5 Bi 0.5 TiO 3 )-xZrO 2 , where x=0.2 mol%.

[0046] Step 1: Preparation of pure phase SrTiO 3 and pure phase Na 0.5 Bi 0.5 TiO 3 spare. Weigh SrCO according to the molar ratio of 1:1 3 and TiO 2 Mix to form mixture A; weigh Bi according to the molar ratio 1:1:4 2 o 3 , Na 2 CO 3 and TiO 2 Mix to form Mixture B. SrCO 3 , Bi 2 o 3 , Na 2 CO 3 and TiO 2 The purity is above 99.0%.

[0047] Step 2: Mix mixtures A and B with zirconium balls and deionized water respectively, according to the mass ratio of 1:2:1.1 and 1:2:1.5, and then use a planetary ball mill for 20 hours, then dry at 90°C for 25 hours 1. After briquetting, place in a box-type furnace for 3.5 hours at 1160° C. and 4.5 hours at 840° C. to form mixtures A and B presynthetic materials respectively for later use.

[0048] Step 3: pre-synthesized material wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com