Double-layer polymer composite material and preparation method thereof

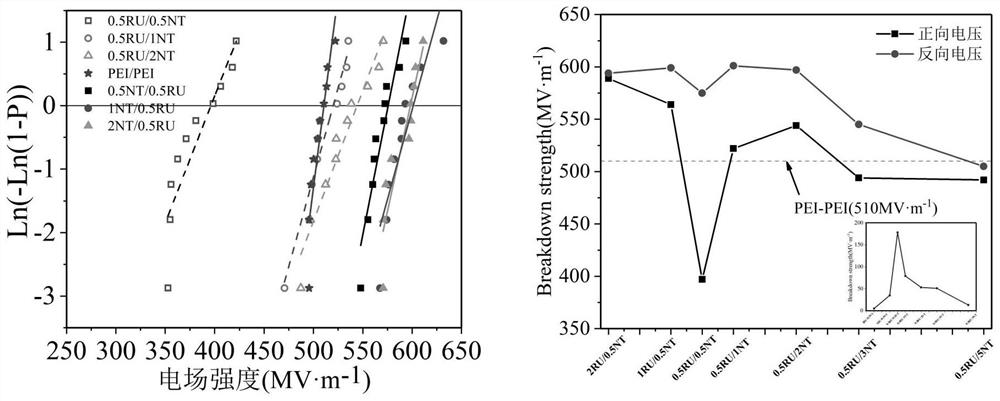

A double-layer polymer and composite material technology, applied in the field of composite materials, can solve the problems of cumbersome preparation process and small breakdown field strength of polymer dielectric films, and achieve the effect of improving breakdown field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

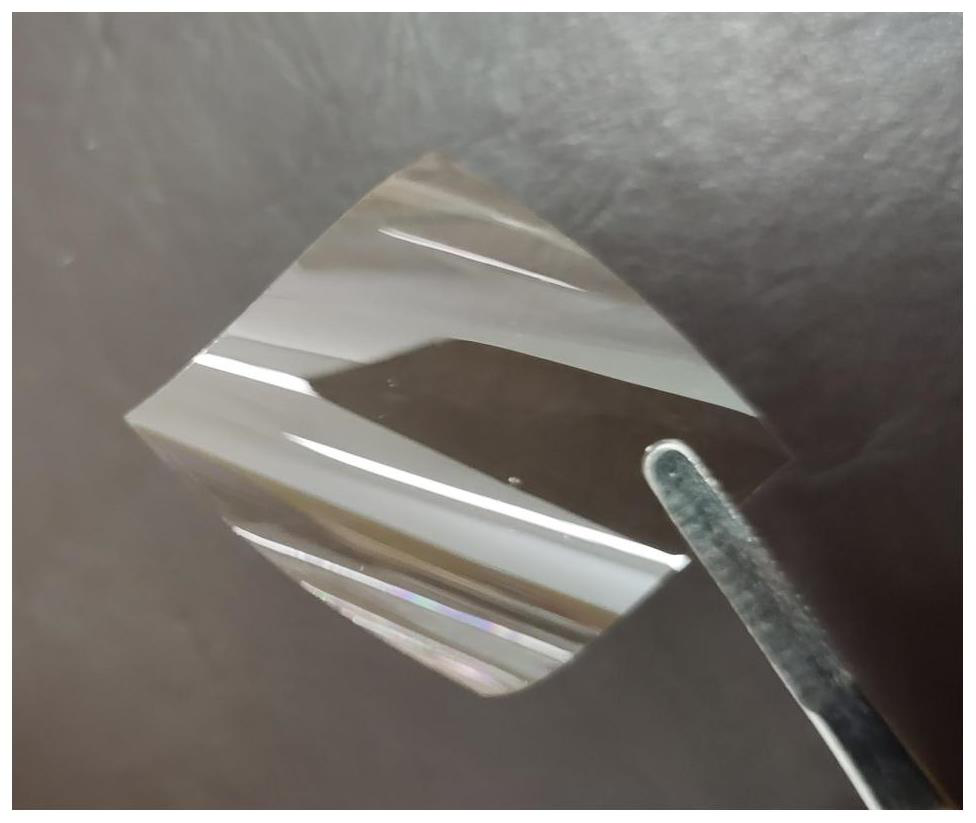

Image

Examples

Embodiment 1

[0033] The preparation process of composite film in the present embodiment is as follows:

[0034] Step 1: Weigh 1 g of polyetherimide (PEI) and place it in 15 ml of N-methylpyrrolidone and heat and stir at 50° C. until the polyetherimide is completely dissolved to prepare a polyetherimide solution. Weigh 0.5vol.% of n-type organic small molecule semiconductor 1,4,5,8-naphthalene tetracarboxylic anhydride (NTCDA), add it to the polyetherimide solution, and stir at room temperature for 10 hours to prepare n-type Precursor slurry. The preparation method of the p-type precursor slurry is the same as that of the n-type, and the p-type small molecule semiconductor rubrene (Rubrene) is selected, weighing 0.5 vol.%.

[0035] Step 2: Take the p-type precursor slurry prepared in step 1 and pass it through a casting machine to cast a film. First, pour the slurry evenly on a clean refractory quartz glass substrate, adjust the height of the scraper, and start the machine to obtain a sing...

Embodiment 2

[0038] The difference from Example 1 is that 1 vol.% of 1,4,5,8-naphthalene tetracarboxylic anhydride (NTCDA) and 0.5 vol.% of rubrene (Rubrene) were weighed. The double-layer polymer dielectric film obtained in this embodiment is recorded as 0.5RU / 1NT.

Embodiment 3

[0040] The difference from Example 1 is that 2 vol.% of 1,4,5,8-naphthalene tetracarboxylic anhydride (NTCDA) and 0.5 vol.% of rubrene were weighed. The double-layer polymer dielectric film obtained in this embodiment is recorded as 0.5RU / 2NT.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com