Image sensor and forming method thereof

An image sensor and amorphous carbon technology, which is applied in the direction of electric solid devices, semiconductor devices, electrical components, etc., can solve the problems of reducing the transmission speed and service life of image sensors, so as to improve service life, increase transmission speed, and high thermal conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

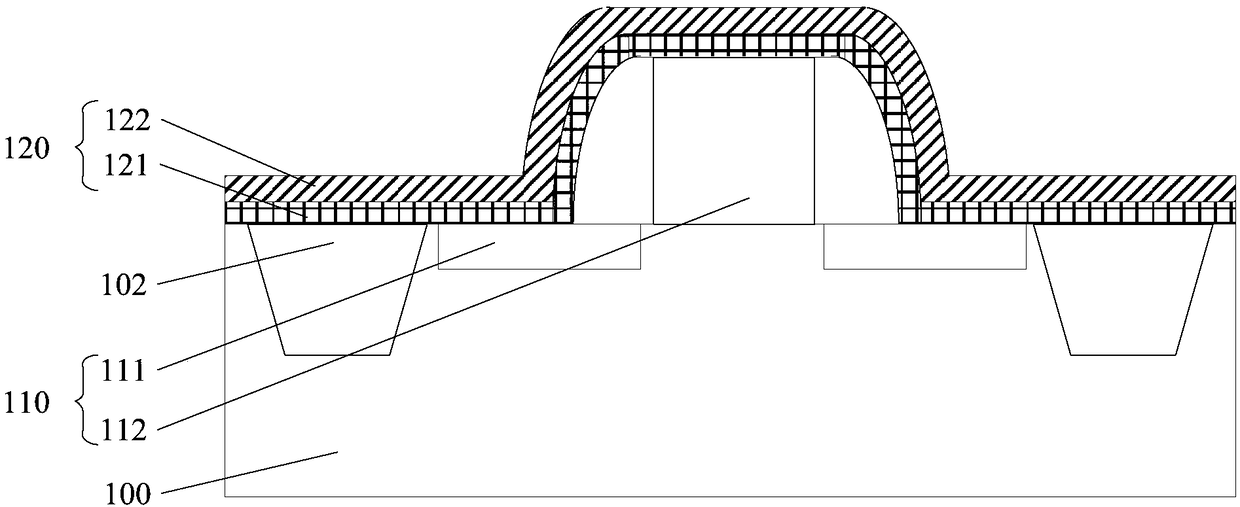

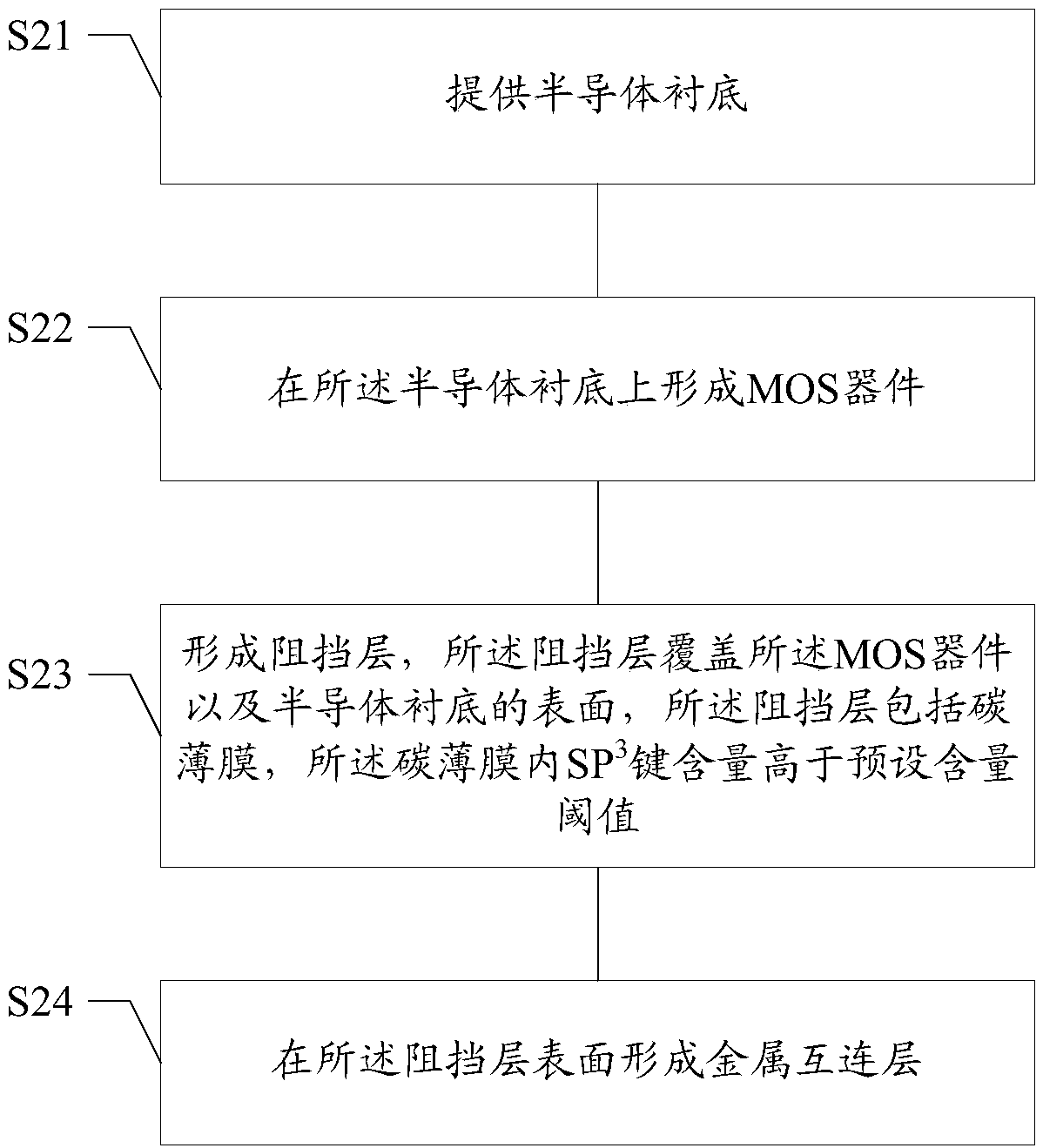

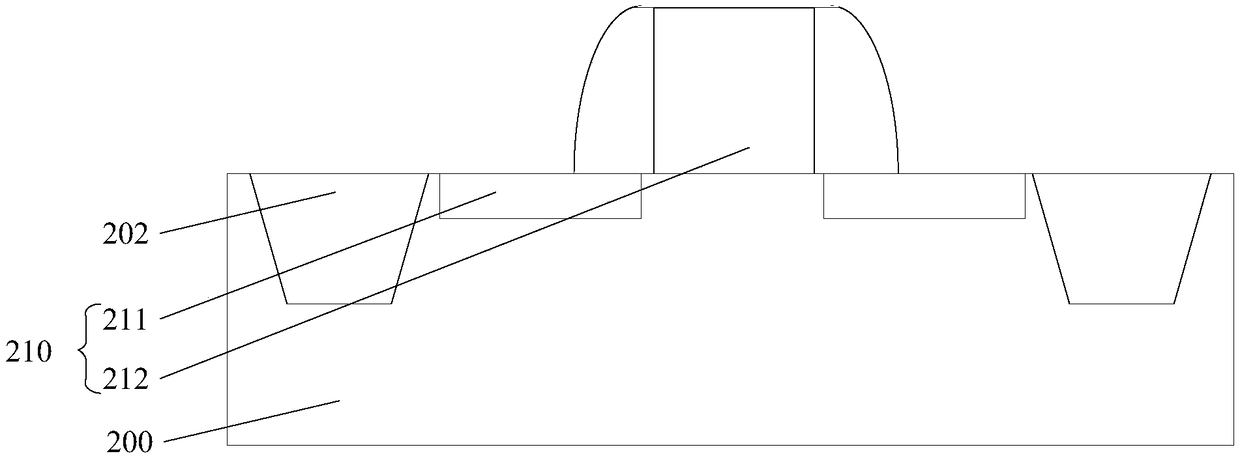

[0023] In the prior art, a semiconductor substrate is provided; a MOS device is formed on the semiconductor substrate; a barrier layer is formed, the barrier layer covers the surface of the MOS device and the semiconductor substrate, the barrier layer includes a carbon film, The carbon film within the SP 3 The bond content is higher than a preset content threshold; a metal interconnection layer is formed on the surface of the barrier layer. Using the above scheme, after forming MOS devices on the semiconductor substrate, silicon nitride and silicon dioxide are usually used as silicide barrier layers to protect the semiconductor substrate and MOS devices, so as to reduce the generation of metal interconnection layers in the subsequent formation. The effect, especially in the pixel area, can effectively reduce the generation of white points through protection.

[0024] refer to figure 1 , figure 1 It is a schematic diagram of a device cross-sectional structure of an image sen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com