Preparation method for lead-based anti-ferroelectric nanometer material and lead-based anti-ferroelectric ceramic energy storage material

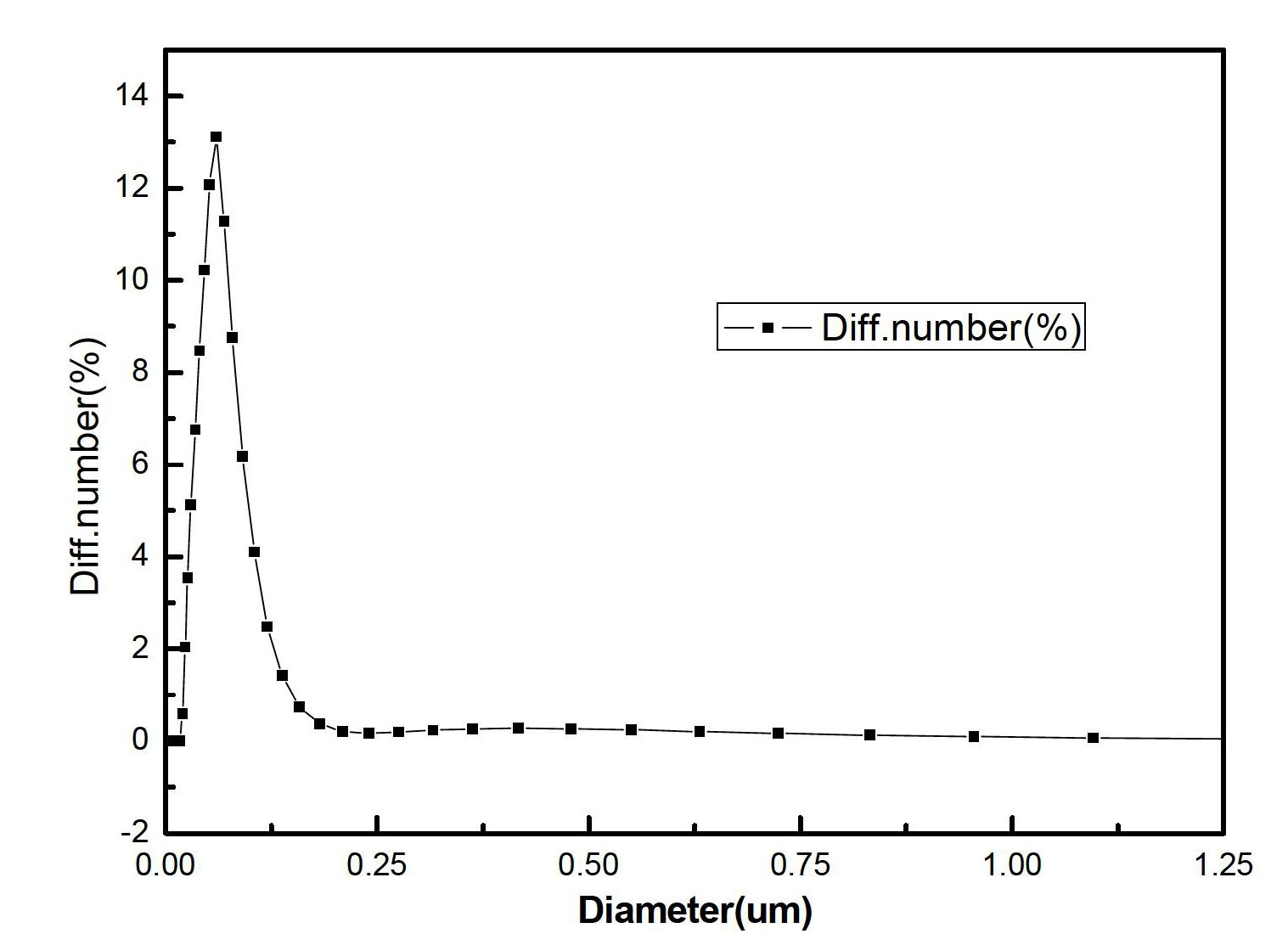

A nano-material and anti-ferroelectric technology, applied in the field of electronic materials and devices, can solve the problems of high reaction phase formation temperature, high synthesis temperature, large crystal grains, etc., and achieve the effect of small particle size and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

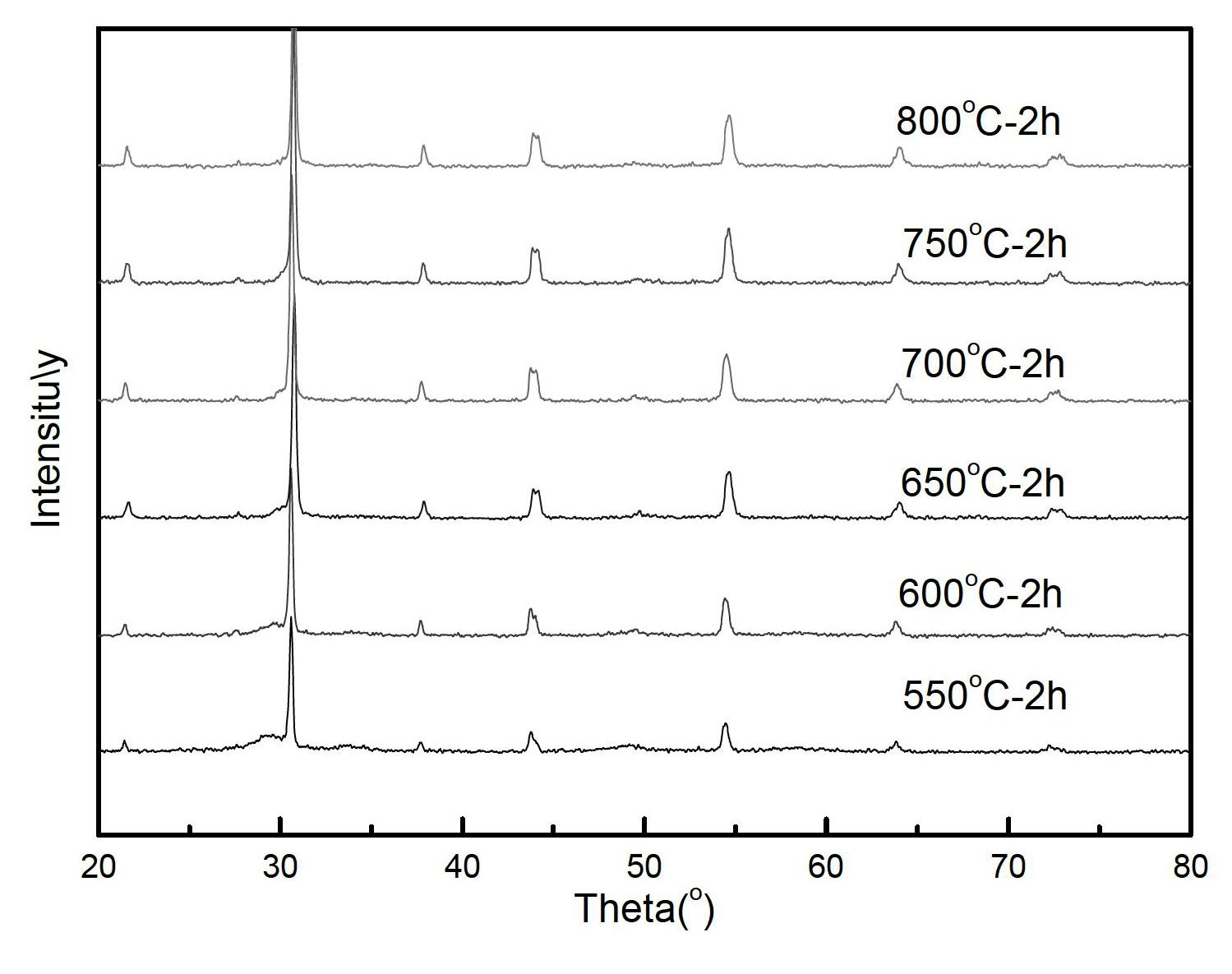

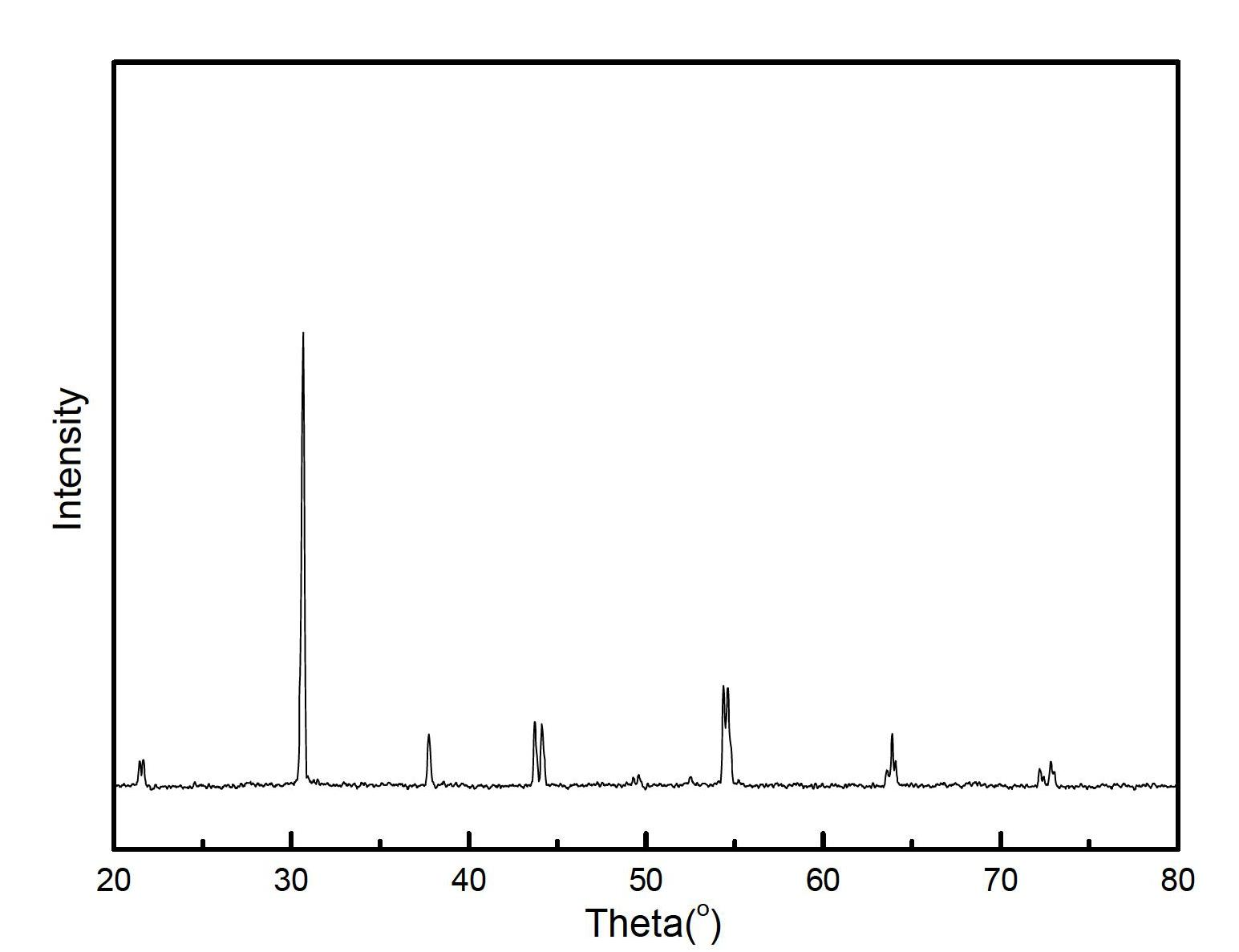

Embodiment 1

[0053] a. Weigh 20g NH 4 Cl was dissolved in 300ml of deionized water, according to the mass ratio of Pb(NO 3 ) 2 :NH 4 Cl=3.1:1, to NH 4 Add 62g Pb(NO 3 ) 2 . Stir for 30 minutes, then filter out the precipitate, take the filtrate to obtain a transparent solution, then add concentrated ammonia water to the solution until the pH of the solution is 9.0, filter out the precipitate, finally add 4.5g PEG6000, stir until completely dissolved, and obtain NH 4 NO 3 -NH 4 OH buffer solution A.

[0054] b. According to the chemical formula Pb 0.97 La 0.02 (Zr 0.75 Ti 0.08 sn 0.17 )O 3 The stoichiometric ratio of Pb, La, Zr, Ti and Sn elements in the medium weighs Pb(Ac) 2 ·3H 2 O or Pb(NO 3 ) 2 , La(NO 3 ) 3 , Zr(NO 3 ) 4 ·5H 2 O, TiCl 4 , SnCl 4 ·5H 2 O, 30g total, then Pb(Ac) 2 ·3H 2 O or Pb(NO 3 ) 2 In excess of 1.5% by weight, La(NO 3 ) 3 The weight of excess 0.6%, Zr(NO 3 ) 4 ·5H 2 The weight of O is in excess of 4%, SnCl 4 ·5H 2 An excess of 3...

Embodiment 2

[0062] a. Weigh 20g NH 4 Cl was dissolved in 300ml of deionized water, according to the mass ratio of Pb(NO 3 ) 2 :NH 4 Cl=3.1:1, to NH 4 Add 62g Pb(NO 3 ) 2 . Stir for 30 minutes, then filter out the precipitate, take the filtrate to obtain a transparent solution, then add concentrated ammonia water to the solution until the solution pH=9.0, filter out the precipitate, finally add 7.5g PEG6000, stir until completely dissolved, and obtain NH 4 NO 3 -NH 4 OH buffer solution A.

[0063] b. According to the chemical formula Pb 0.97 La 0.02 (Zr 0.54 Ti 0.08 sn 0.38 )O 3 The stoichiometric ratio of Pb, La, Zr, Ti and Sn elements in the medium weighs Pb(Ac) 2 ·3H 2 O or Pb(NO 3 ) 2 , La(NO 3 ) 3 , Zr(NO 3 ) 4 ·5H 2 O, TiCl 4 , SnCl 4 ·5H 2 O, 40g total, then Pb(Ac) 2 ·3H 2 O or Pb(NO 3 ) 2 In excess of 1.5% by weight, La(NO 3 ) 3 The weight of excess 0.6%, Zr(NO 3 ) 4 ·5H 2 The weight of O is in excess of 4%, SnCl 4 ·5H 2 An excess of 3% by weigh...

Embodiment 3

[0072] Preparation of Pb 0.97 La 0.02 (Zr 0.60 Ti 0.05 sn 0.35 )O 3 Antiferroelectric nanopowder materials and antiferroelectric ceramic energy storage materials:

[0073] a. Weigh 20gNH 4 Cl was dissolved in 300ml of deionized water, according to the mass ratio of Pb(NO 3 ) 2 :NH 4 Cl=3.1:1, to NH 4 Add 62g Pb(NO 3 ) 2 . Stir for 30 minutes, then filter out the precipitate, take the filtrate to obtain a transparent solution, then add concentrated ammonia water to the solution until the pH of the solution is 9.0, filter out the precipitate, finally add 7.0g PEG6000, stir until completely dissolved, and obtain NH 4 NO 3 -NH 4 OH buffer solution A.

[0074] b. According to the chemical formula Pb 0.97 La 0.02 (Zr 0.60 Ti 0.05 sn 0.35 )O 3 The stoichiometric ratio of Pb, La, Zr, Ti and Sn elements in the medium weighs Pb(Ac) 2 ·3H 2 O or Pb(NO 3 ) 2 , La(NO 3 ) 3 , Zr(NO 3 ) 4 ·5H 2 O, TiCl 4 , SnCl 4 ·5H 2 O, 40g total, then Pb(Ac) 2 ·3H 2 O or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com