Sandwich-structured high-dielectric flexible composite film and preparation method thereof

A composite film and sandwich technology, applied in chemical instruments and methods, lamination devices, rubber layered products, etc., can solve the problems of low electromechanical conversion efficiency, slow polarization reversal response, limited applications, etc., and achieve high breakdown The effect of field strength, high dielectric constant, and widening application space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Weigh 2.5 g each of the precursor of polydimethylsiloxane and the organic solvent n-heptane, and then magnetically stir for 10 min to make them evenly mixed.

[0030] (2) Add 0.25 g of curing agent and stir magnetically for 10 min to make it evenly mixed to obtain a mixed solution with a total weight of 5.25 g.

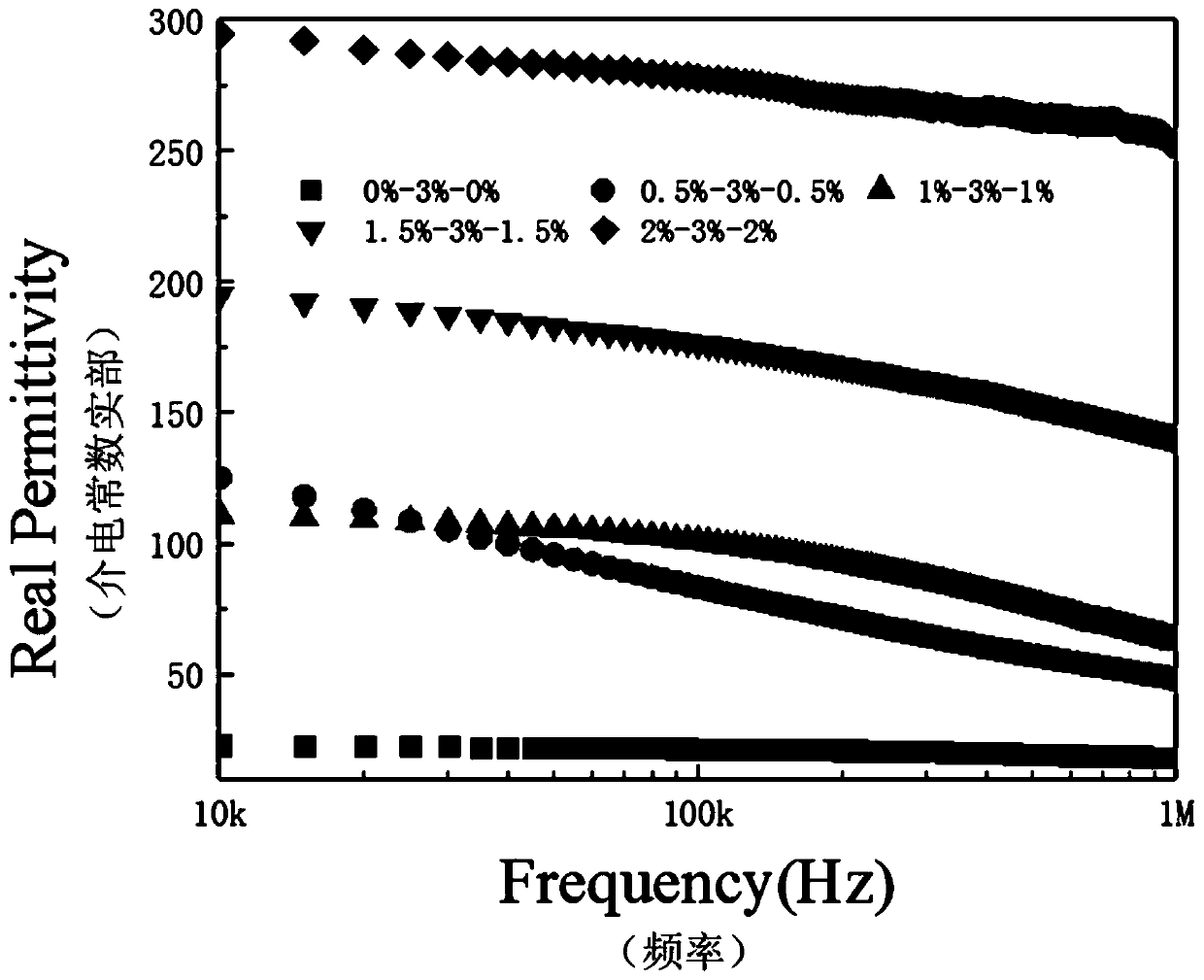

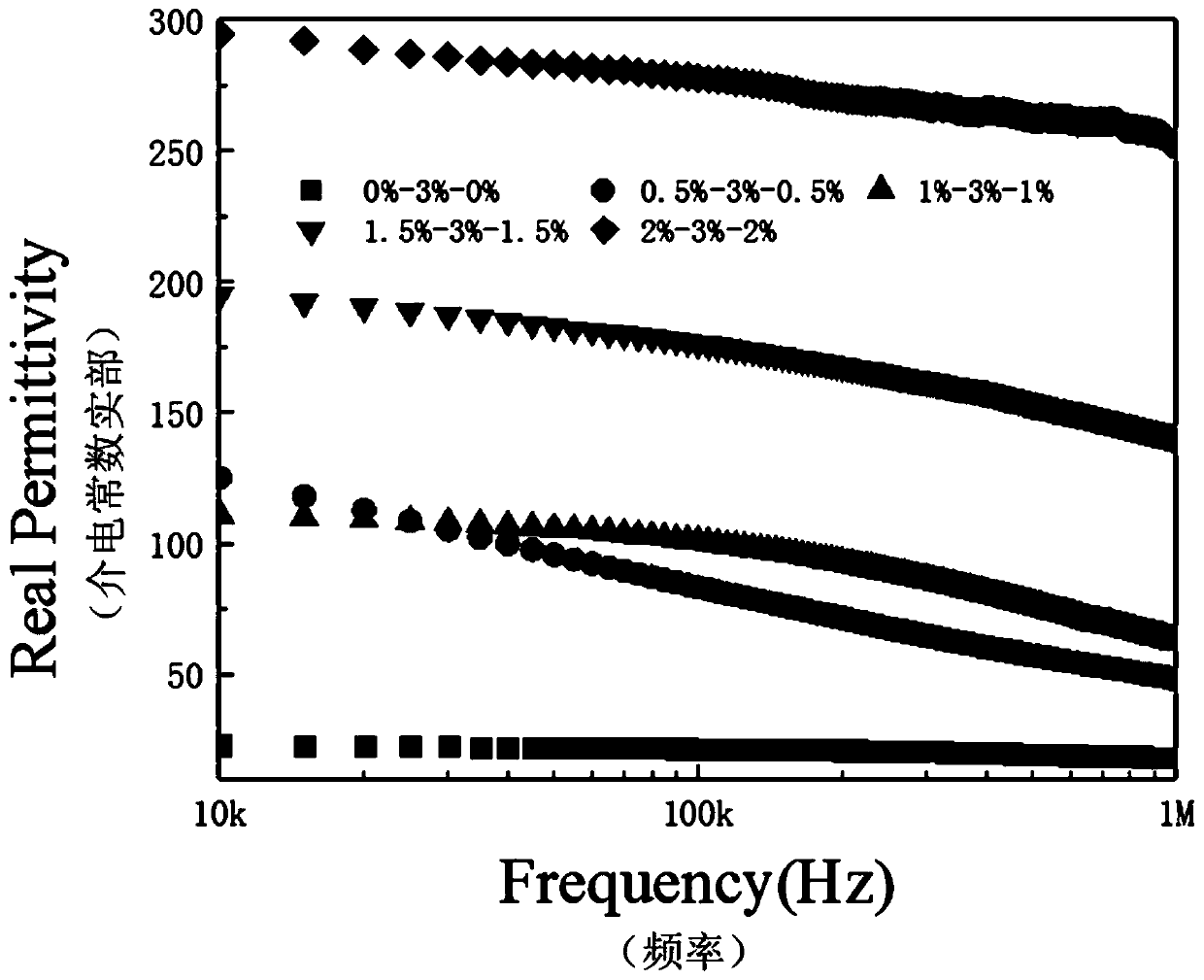

[0031] (3) Add carbon nanotubes to the mixed solution according to the calculated mass ratio, and the obtained slurries A and B are used to prepare coatings with positive and negative dielectric constants respectively, wherein the carbon nanotubes added in the slurry A It is 0.0263g (the mass percentage of the carbon nanotubes added and the mixed solution is 0.5%), which is used to prepare the upper and lower film with a positive dielectric constant, that is, to prepare the first outer layer and the second outer layer with a positive dielectric constant. Two outer layers. In order to ensure the structural uniformity of the upper and lower films, the mass f...

Embodiment 2

[0036] (1) Weigh 2.5 g each of the precursor of polydimethylsiloxane and the organic solvent n-heptane, and then magnetically stir for 10 min to make them evenly mixed.

[0037] (2) Add 0.25 g of curing agent and stir magnetically for 10 min to make it evenly mixed to obtain a mixed solution with a total weight of 5.25 g.

[0038] (3) Add carbon nanotubes according to the calculated mass ratio, and the obtained slurry A and B are used to prepare coatings with positive and negative dielectric constants respectively, wherein slurry A adds 0.053g carbon nanotubes (the added carbon nanotubes The mass ratio of tube and mixed solution is 1%), prepare upper and lower film with positive dielectric constant, promptly be used for preparing the first outer layer and the second outer layer with positive dielectric constant; Slurry B adds 0.1624g carbon nanotubes (the mass ratio of the added carbon nanotubes to the mixed solution is 3%), and an intermediate layer film with a negative diele...

Embodiment 3

[0043] (1) Weigh the precursor of polydimethylsiloxane and the organic solvent n-heptane 2.5g, and then magnetically stir for 10min to make them evenly mixed.

[0044] (2) Add 0.25 g of curing agent and stir magnetically for 10 min to make it evenly mixed to obtain a mixed solution with a total weight of 5.25 g.

[0045] (3) Add carbon nanotubes according to the calculated mass ratio, and the obtained slurry A and B are used to prepare coatings with positive and negative dielectric constants respectively, wherein slurry A adds 0.08g carbon nanotubes (the added carbon nanotubes The mass ratio of tube and mixed solution is 1.5%), prepare upper and lower film with positive dielectric constant, namely be used to prepare the first outer layer and the second outer layer with positive dielectric constant; Slurry B adds 0.1624g carbon nanotubes (the mass ratio of the added carbon nanotubes to the mixed solution is 3%), and an intermediate layer film with a negative dielectric constant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com