Foam buffer adhesive tape for electronic products and preparation method thereof

A technology of electronic products and foams, applied in adhesives, film/sheet-like adhesives, pressure-sensitive films/sheets, etc., can solve problems such as difficult to achieve interlayer damage, difficult to control cells, poor reworkability, etc., and achieve considerable Effects of anti-drop damage, good sealing protection, and good reworkability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

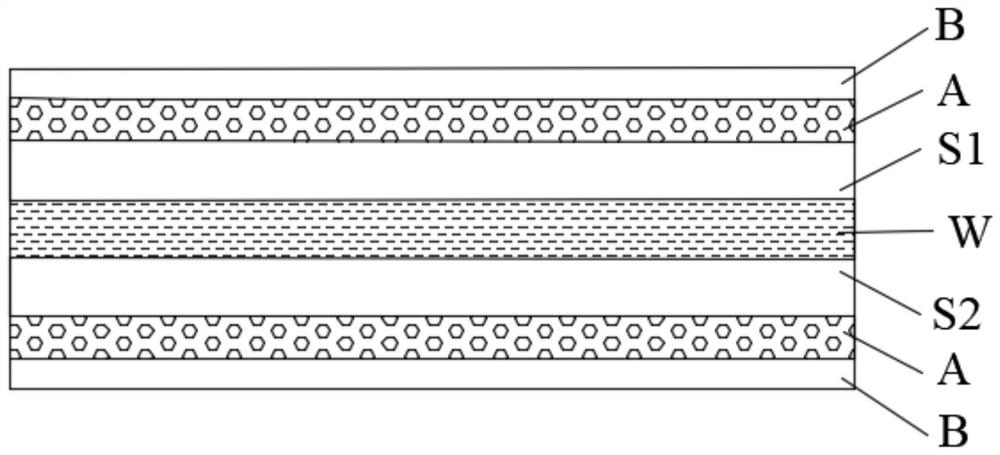

[0055] The structure of the foam buffer tape of this embodiment is composed of a foam center main body layer, an adhesive layer, and a release film, wherein the adhesive layer is distributed on both sides of the foam center main body layer, and the release film is distributed on the adhesive layer On both sides, the release film is silicone oil-coated release paper, the adhesive layer is pressure-sensitive acrylic adhesive, and the bonding strength between the adhesive layer and the central main body layer is 8N / 25cm.

[0056] In this embodiment, the foam central body layer is composed of three layers, including the foam layer as the middle layer and the foam layer S1 and foam layer S2 located on both sides of the middle layer. The cohesive energy strength of the foam layer S1 and the foam layer S2 is 12N / 25cm, and the cohesive energy strength of the foam layer W is 4N / 25cm.

[0057] Wherein the foam layer W consists of the following formula:

[0058] 8 parts of resin A, 80 p...

Embodiment 2

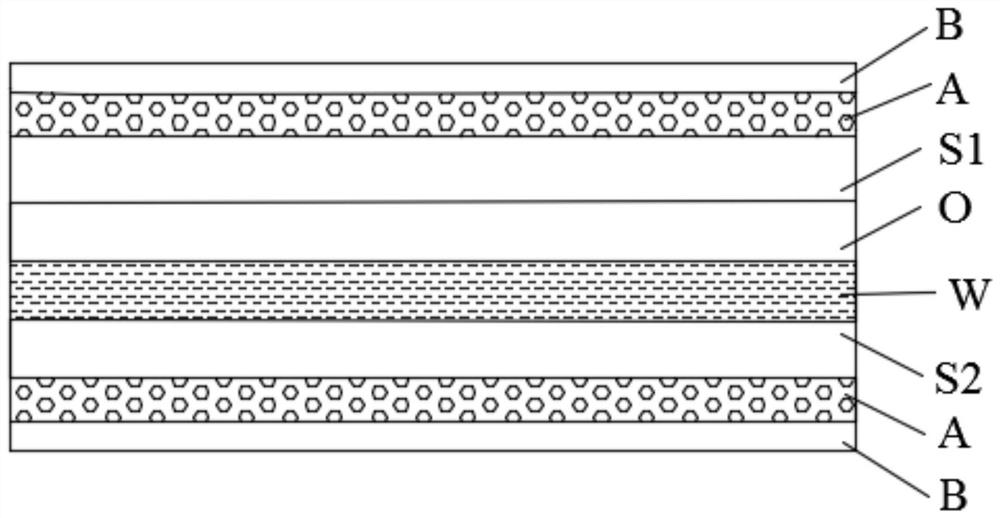

[0063] The structure of the foam buffer tape of this embodiment is composed of a foam center main body layer, an adhesive layer, and a release film, wherein the adhesive layer is distributed on both sides of the foam center main body layer, and the release film is distributed on the adhesive layer On both sides, the release film is silicone oil-coated release paper, the adhesive layer is pressure-sensitive acrylic adhesive, and the bonding strength between the adhesive layer and the central main body layer is 8N / 25cm.

[0064] The main body layer of the foam center is composed of a three-layer structure, including the foam layer W in the middle layer, the foam layer S1 and the foam layer S2 on the upper and lower sides. The cohesive energy of the foam layer S1 is 25N / 25cm, the cohesive energy strength of the foam layer S2 is 12N / 25cm, and the cohesive energy strength of the foam layer W is 5N / 25cm.

[0065] Wherein the foam layer W consists of the following formula: 8 parts of...

Embodiment 3

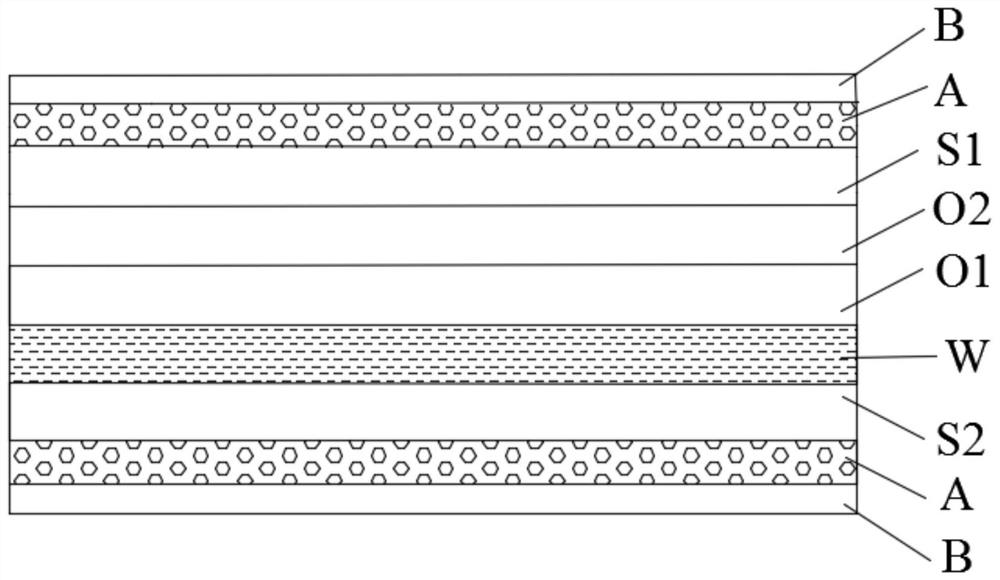

[0074] The structure of the foam buffer tape of this embodiment is composed of a foam center main body layer, an adhesive layer, and a release film, wherein the adhesive layer is distributed on both sides of the foam center main body layer, and the release film is distributed on the adhesive layer On both sides, the release film is silicone oil-coated release paper, and the adhesive layer is pressure-sensitive acrylic resin. The bonding strength of the adhesive layer and the central body layer is 8N / 25cm.

[0075] The main body layer of the foam center consists of a 4-layer structure, including the foam layer W in the middle layer, the foam layer S1 and the foam layer S2 on the upper and lower sides, and the foam distributed between the foam layer W and the foam layer S1 Layer O. The cohesive energy strength of the foam layers S1 and S2 is 12N / 25cm, the cohesive energy strength of the foam layer W is 5N / 25cm, and the cohesive energy of the foam layer O is 25N / 25cm.

[0076] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com