Edge cutting device for tailoring

A technology for trimming and clothing, applied in the field of clothing processing, can solve problems such as troublesome multilateral cutting of fabrics, and achieve the effects of improving overall work efficiency, preventing uneven cutting, pressing and fixing and easy to take out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

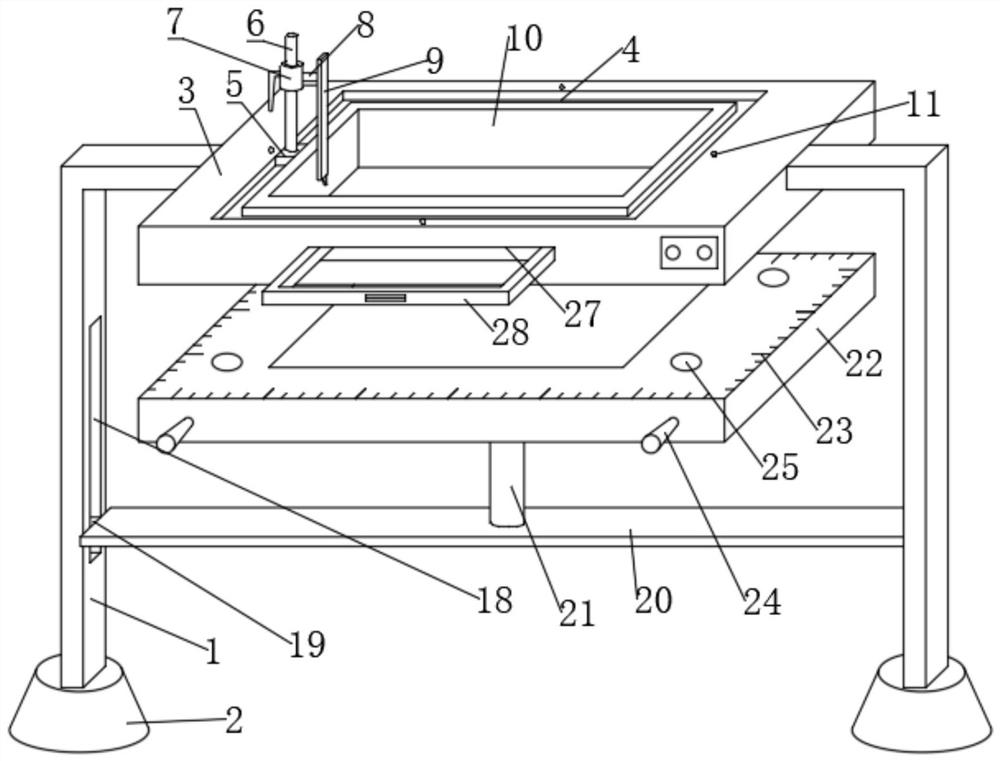

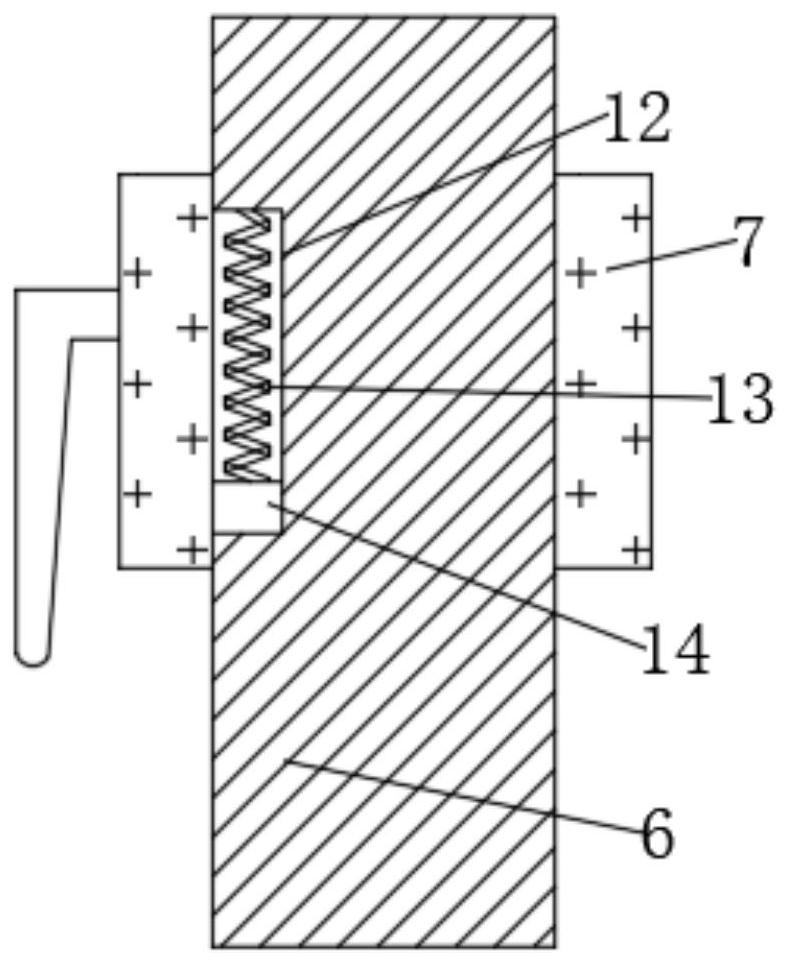

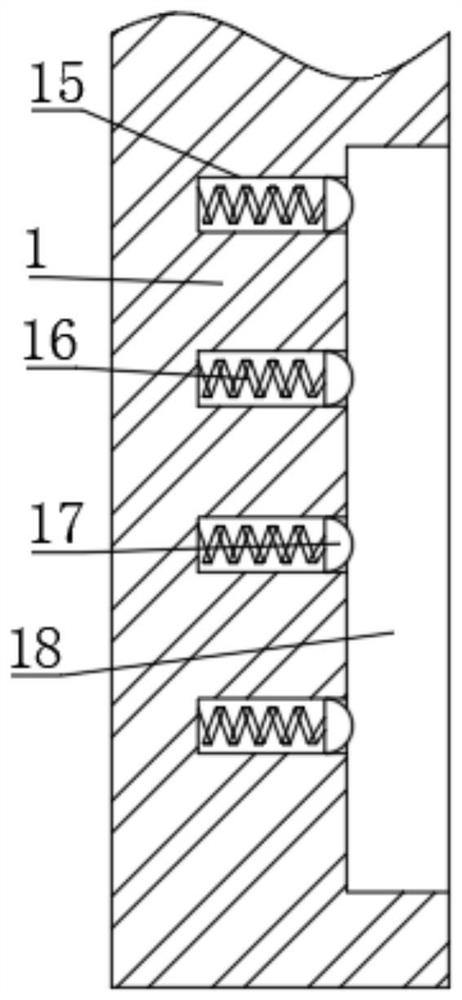

Embodiment 1

[0026] refer to Figure 1-4 , an edge trimming device for garment processing, comprising two pillars 1, the bottom of the pillars 1 is fixed with a base 2 by bolts, the section of the pillars 1 is set in an L-shape, and the same edge cutting table 3 is fixed between the two pillars 1 by bolts There is an opening 10 through the top of the trimming table 3, a chute 4 is provided on the top of the trimming table 3, the chute 4 is arranged on the periphery of the opening 10, the cross section of the chute 4 is set as a rectangle, and the first chute is slidably connected in the chute 4 Block 5, the top of the first slider 5 is connected with the first support rod 6 through the hinge rotation, the first support rod 6 is covered with a sleeve 7, the outer side of the sleeve 7 is fixed with a handle by bolts, and the other side of the sleeve 7 is passed through Bolts are fixed with a second pole 8, the inside of the second pole 8 is fixed with a knife rest 9 by bolts, the bottom of t...

Embodiment 2

[0030] refer to Figure 1-5 , an edge trimming device for garment processing, a fourth groove 27 is provided at the front end and the rear end of the edge trimming table 3, and the two fourth grooves 27 are arranged in a dislocation up and down, and a pull rod 28 is inserted into the fourth groove 27, Pull rod 28 front end is fixed with handle by bolt, and the bottom of the fourth groove 27 inner wall offers limit groove 29, and the limit block 30 is slidably connected in limit groove 29, and limit block 30 top is fixedly connected with pull rod 28 bottoms.

[0031]When in use, after the cloth is fixed, the pull bar 28 is pulled out from the fourth groove 27 by the handle, one end of the cloth is held with both hands respectively, and the wrists are pressed against both sides of the pull bar 28, and the cloth is pulled along the pull bar 28 , can make the side cutter cut the cloth in the process of pulling the cloth, and the effect of the pull rod 28 ensures that the arm moves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com