Rapid binding device for steel reinforcement framework of high and large pier body and construction method of rapid binding device

A technology of steel bars and steel skeletons for pier bodies, applied in the erection/assembly of bridges, bridge parts, bridges, etc., can solve the problems of high-altitude operation, long construction period, low construction work efficiency, etc., to protect effective rigidity and ensure construction quality. , the effect of shortening the construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

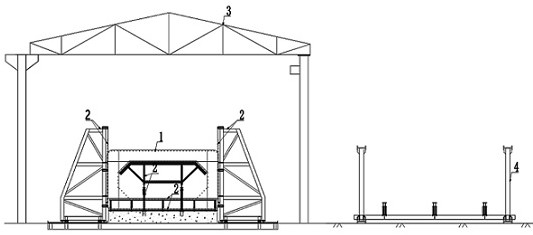

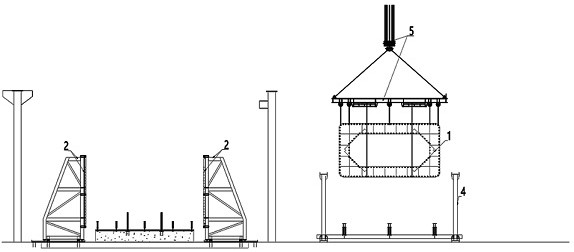

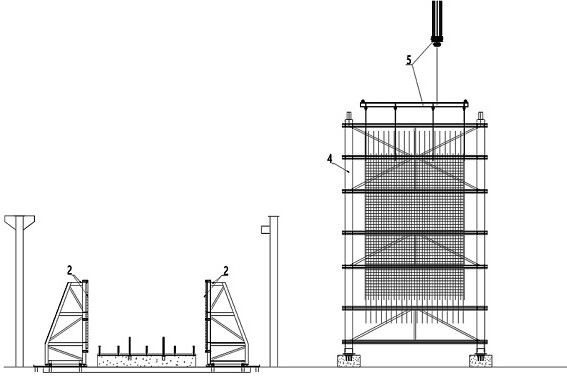

[0029] Below in conjunction with accompanying drawing, technical solution of the present invention is further described:

[0030] combined with Figure 1-6 , a method for rapid construction of a steel frame for a tall pier body, the structure of which includes a steel bar binding frame 2, a ceiling 3, a steering structure 4, a lifting system 5, a steel frame 6 in place, an inner mold system 7, an outer mold system 8 and a bottom Formwork system or platform structure9. The steel frame 1 is turned from horizontal to vertical through the steering structure 4, and the steel frame 1 enters the installation area from the binding area through the lifting system 7 to realize the installation or docking of the steel frame 1.

[0031] It also includes a ceiling 5, which is arranged above the horizontal binding tire frame.

[0032] Its construction method includes the following steps:

[0033] 1) Horizontal binding: the steel frame 1 is horizontally bound on the horizontal binding fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com