Patents

Literature

32results about How to "Controlled plastic deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

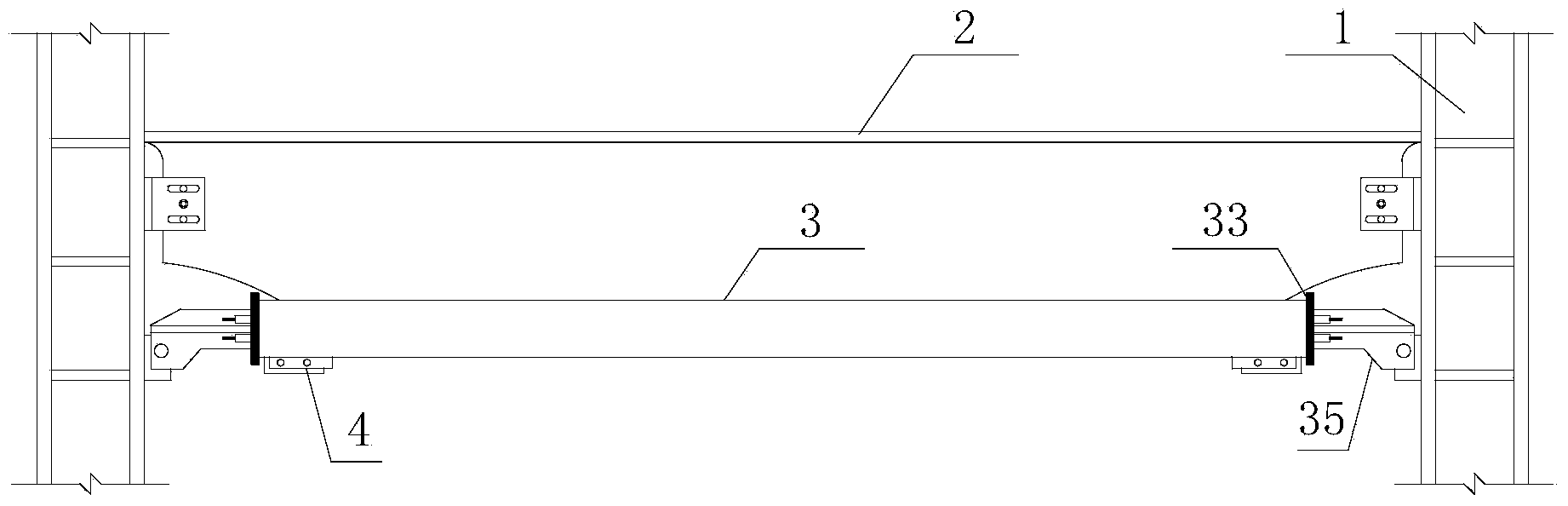

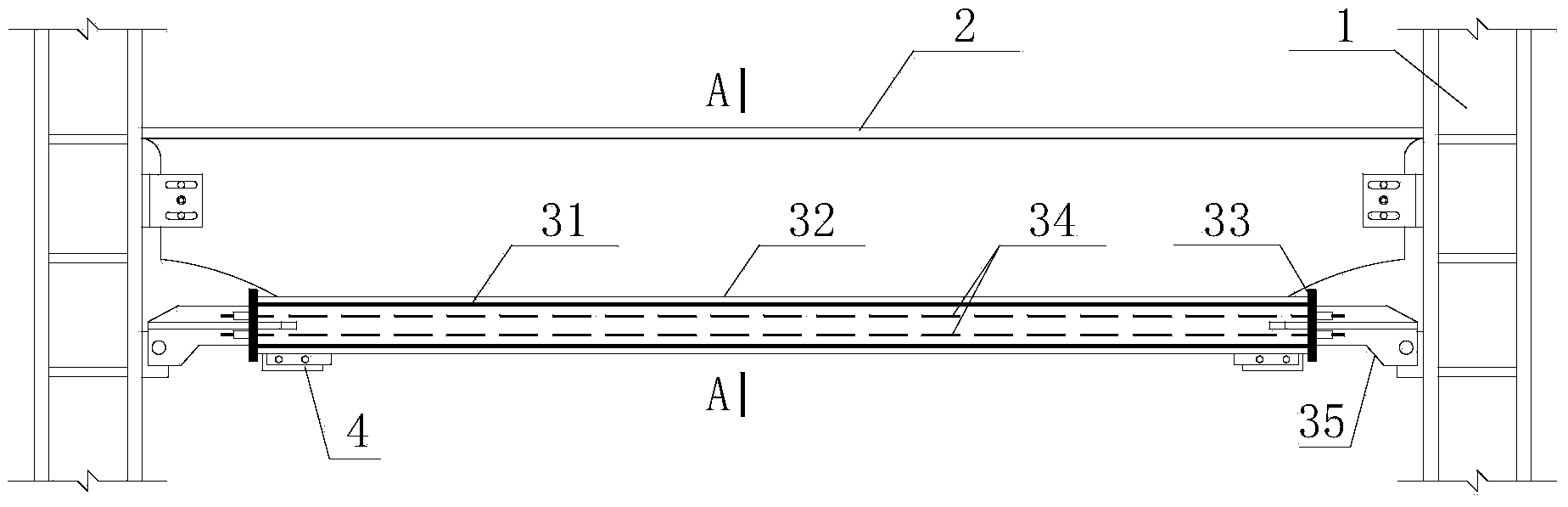

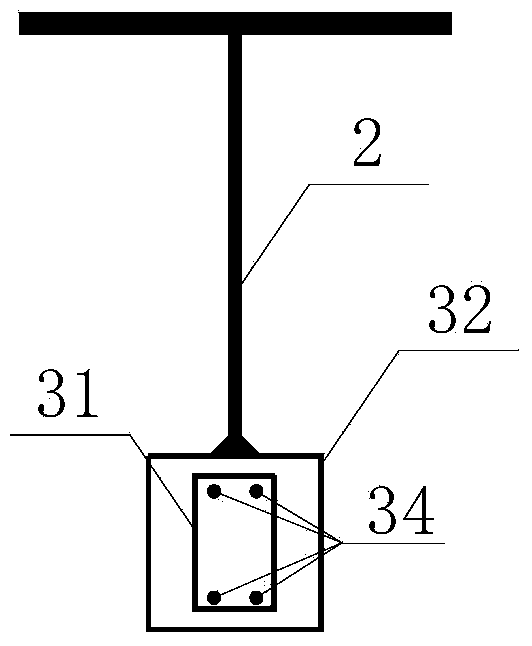

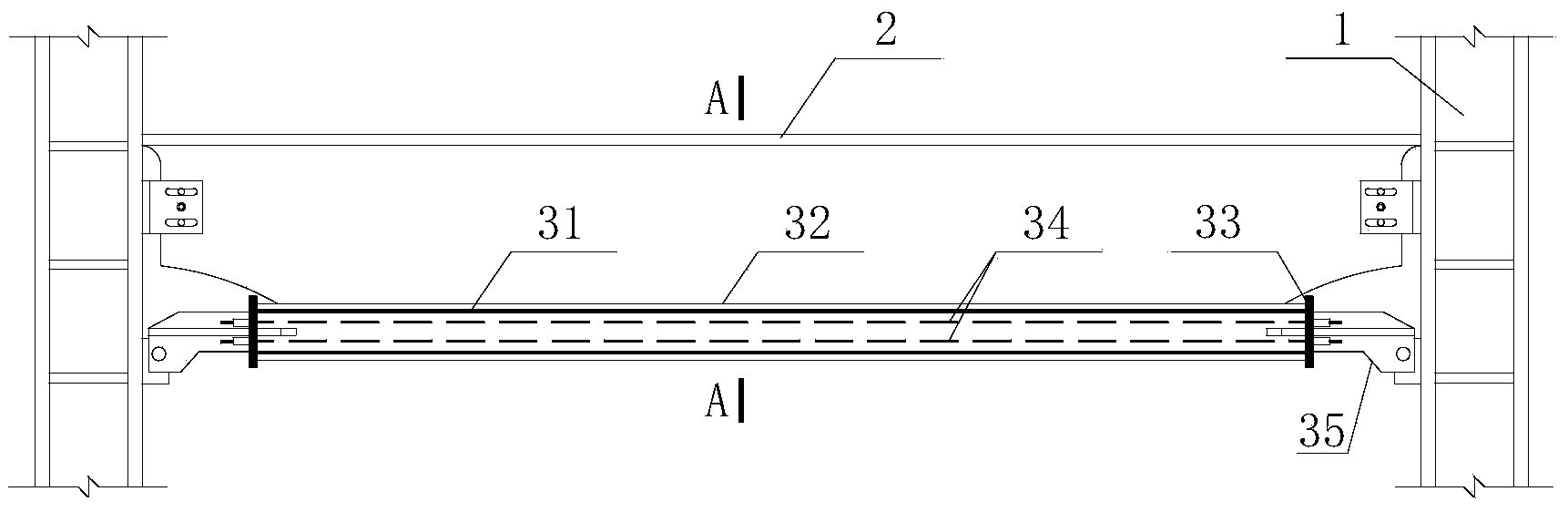

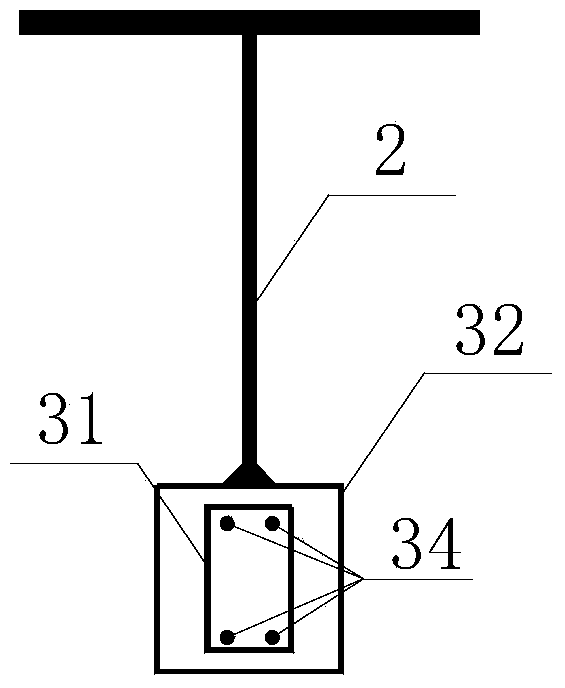

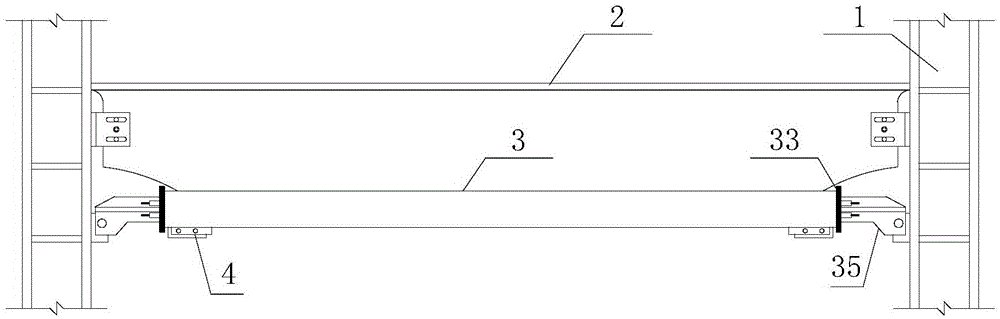

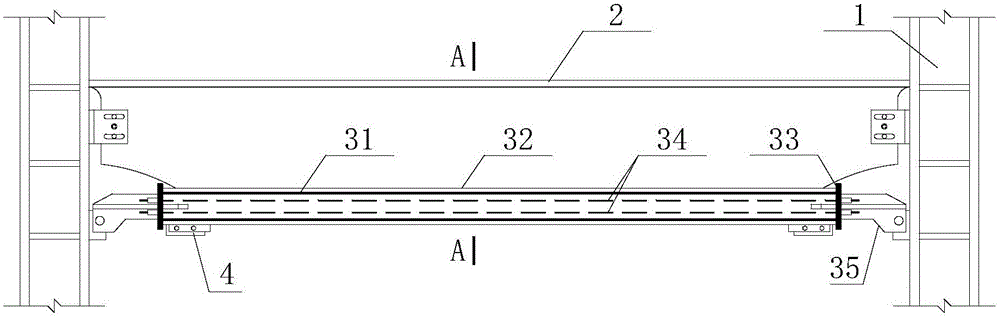

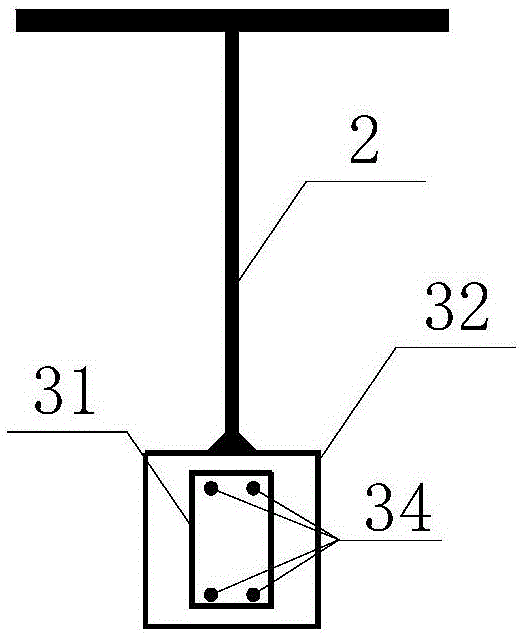

Post-tensioning prestress type self-centering steel frame structure

The invention discloses a post-tensioning prestress type self-centering steel frame structure. The post-tensioning prestress type self-centering steel frame structure comprises at least one structural unit. Each structural unit comprises two steel frame columns, a T-shaped steel beam, a self-centering connecting piece and friction energy consumption parts, wherein the T-shaped steel beam is used for connecting the upper ends of the steel frame columns, the self-centering connecting piece is located on the lower side of the T-shaped steel beam and used for connecting the steel frame columns, and the friction energy consumption parts are located on the lower portion of the self-centering connecting piece. Each self-centering connecting piece comprises an inner sleeve, an outer sleeve, end plates, pretensioning rods and connectors, wherein the inner sleeve is sleeved with the outer sleeve, the end plates are located at the two ends of the sleeves, the pretensioning rods are arranged in the inner sleeve and anchored on the end plates, and the connectors are connected with the ends of the inner sleeve. Each friction energy consumption part comprises an inner friction plate, an outer friction plate and a friction gasket, wherein the inner friction plate is connected with the inner sleeve, the outer friction plate is connected with the lower side face of the outer sleeve, the friction gasket is arranged between the inner friction plate and the outer friction plate, and the sliding direction of the inner friction plate and the sliding direction of the outer friction plate are arranged in the axial direction of the outer sleeve. Column space is kept unchanged when the columns are laterally deformed, and the strength, the rigidity and the ductility of the structure can be flexibly and independently adjusted and controlled in the design process.

Owner:SOUTHEAST UNIV

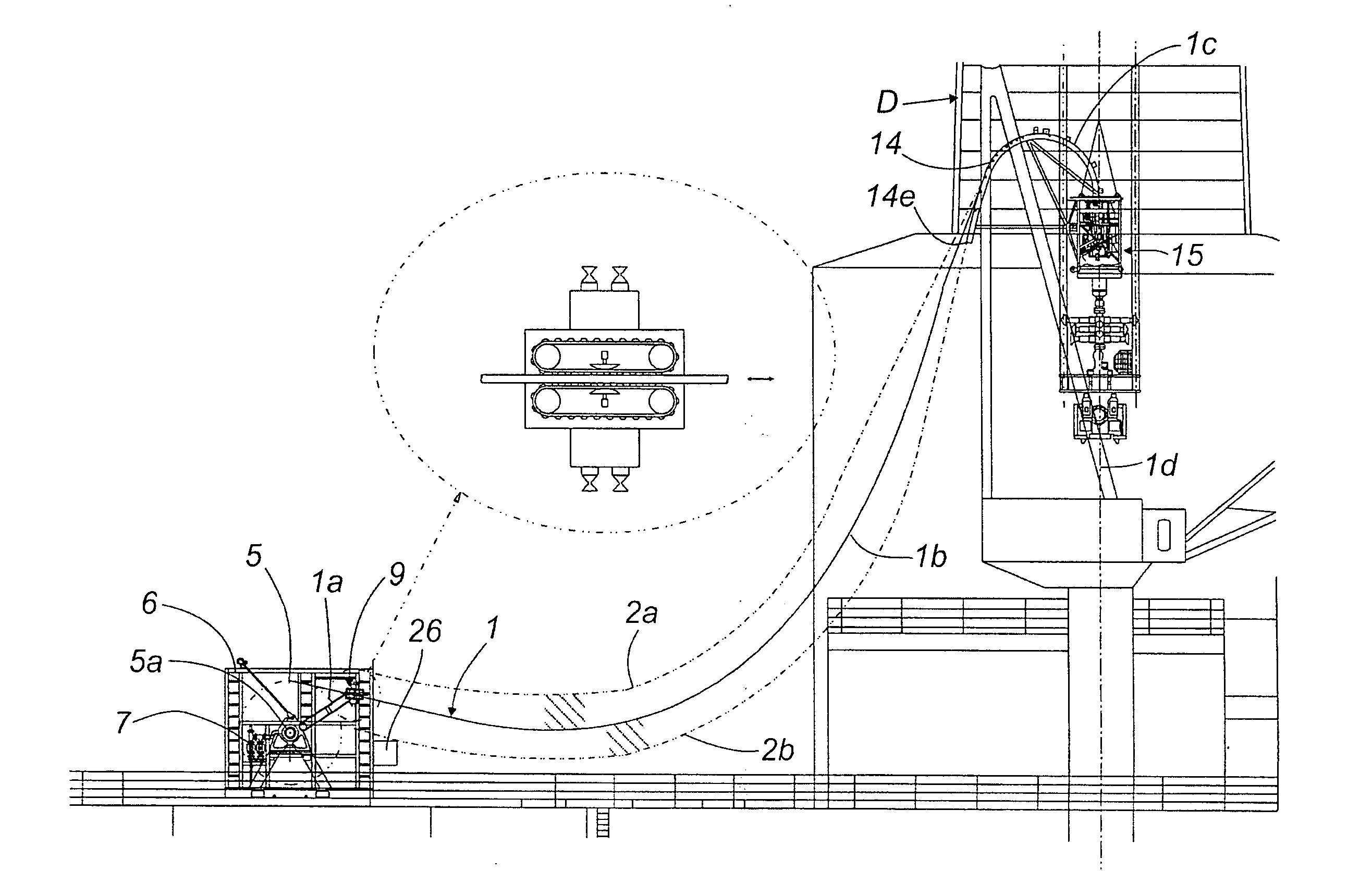

Apparatus and method

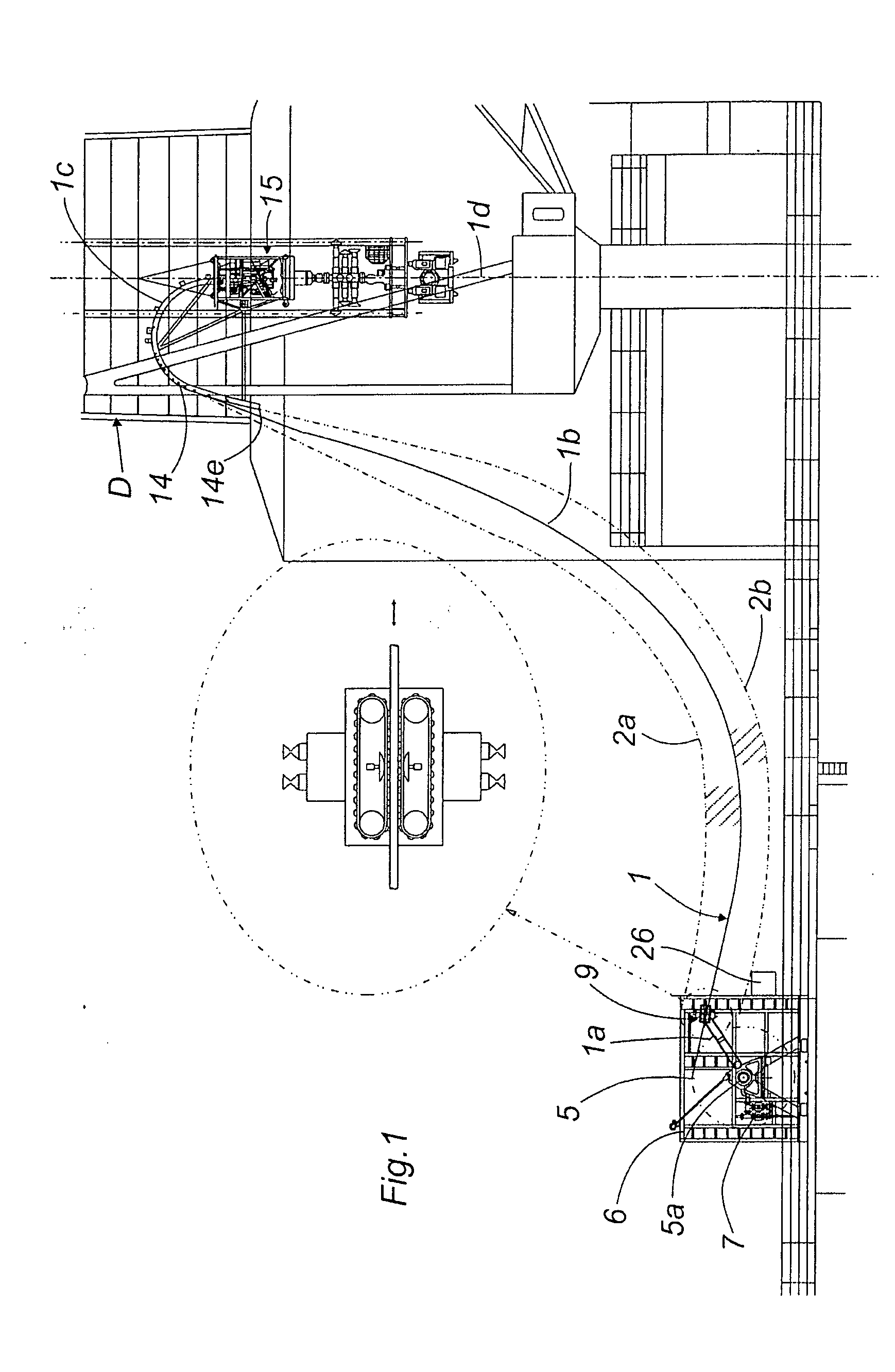

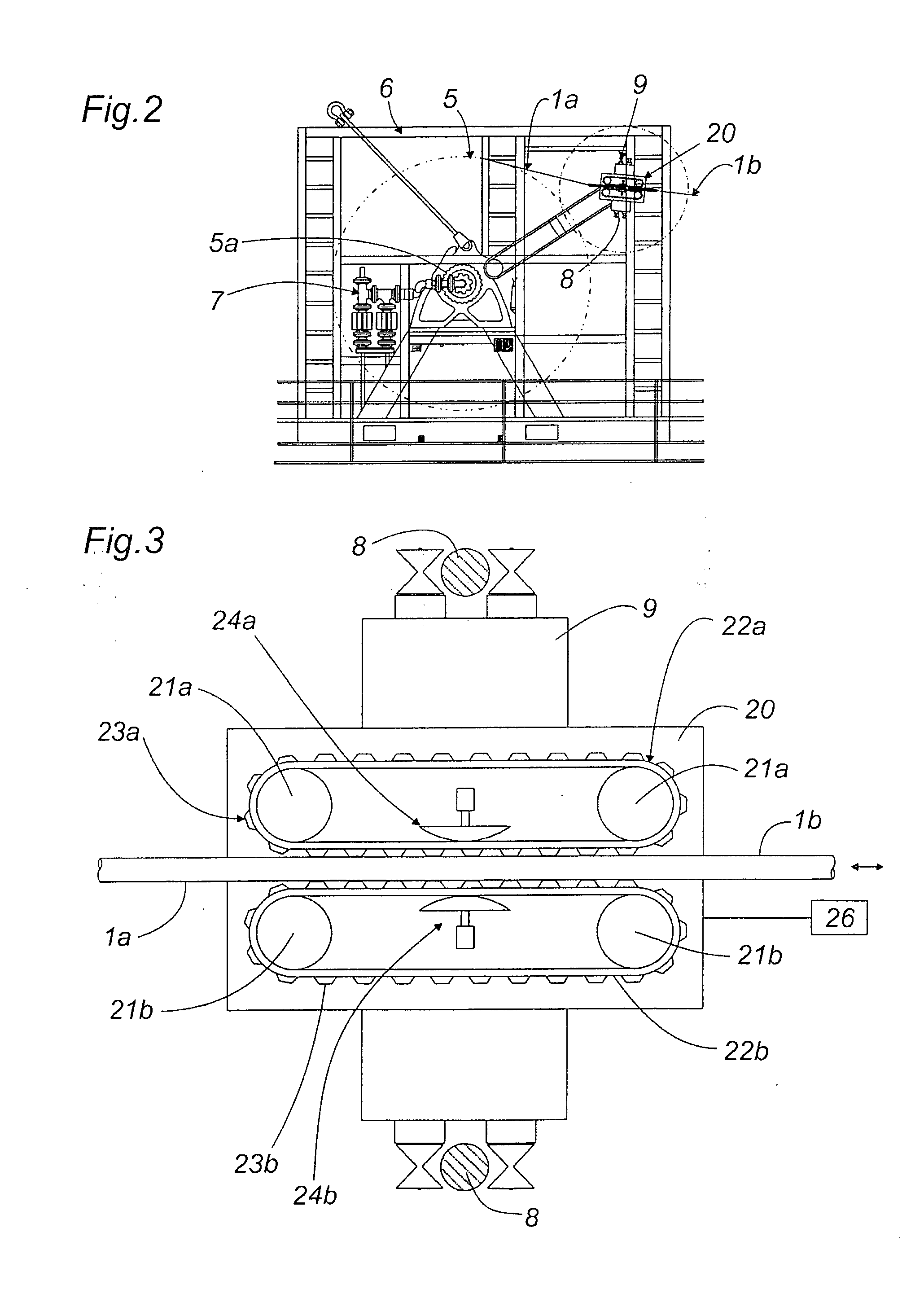

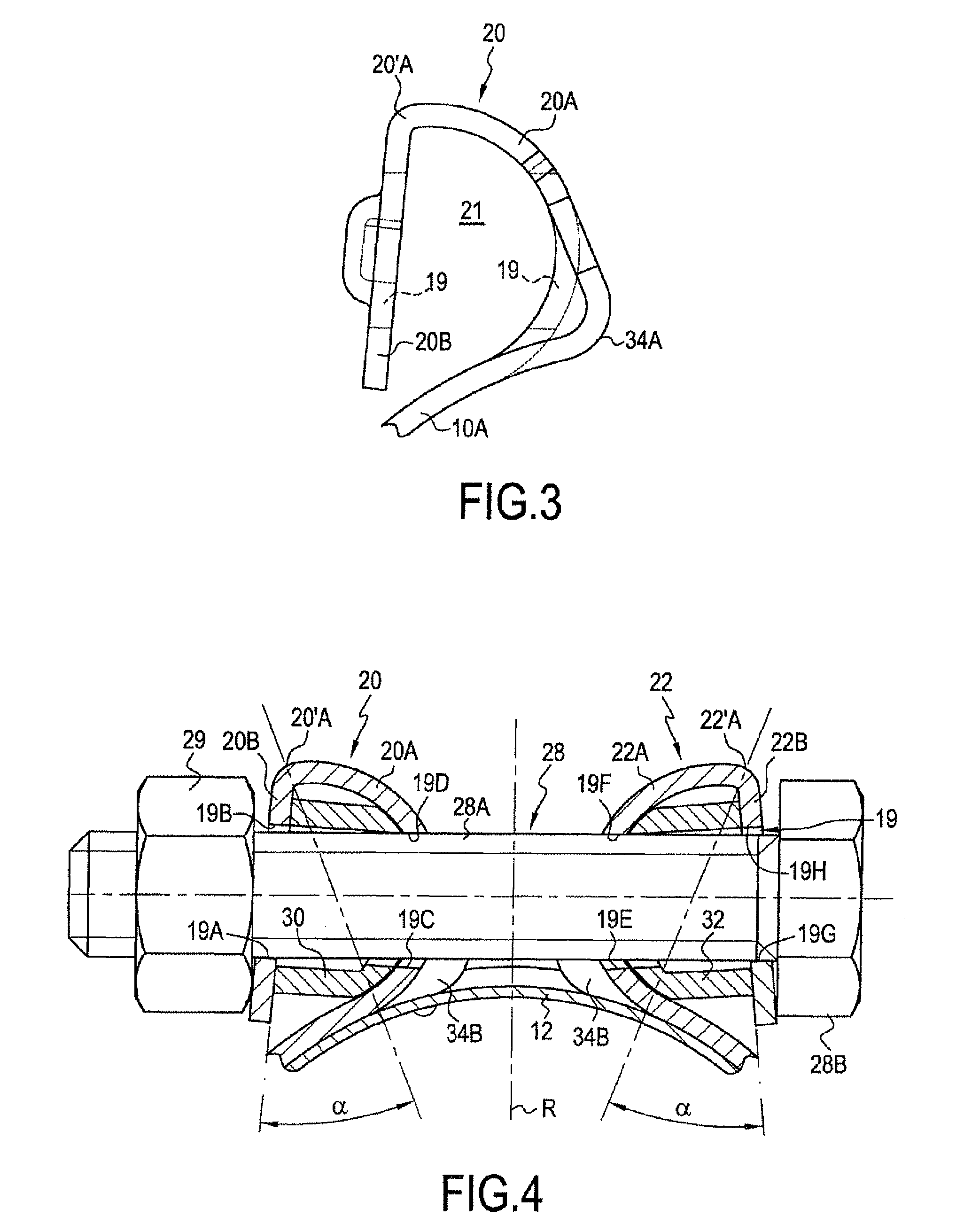

InactiveUS20090223677A1Reduce fatiguePlastic deformation is avoided and mitigatedDrilling rodsProjector film strip handlingCoiled tubingEngineering

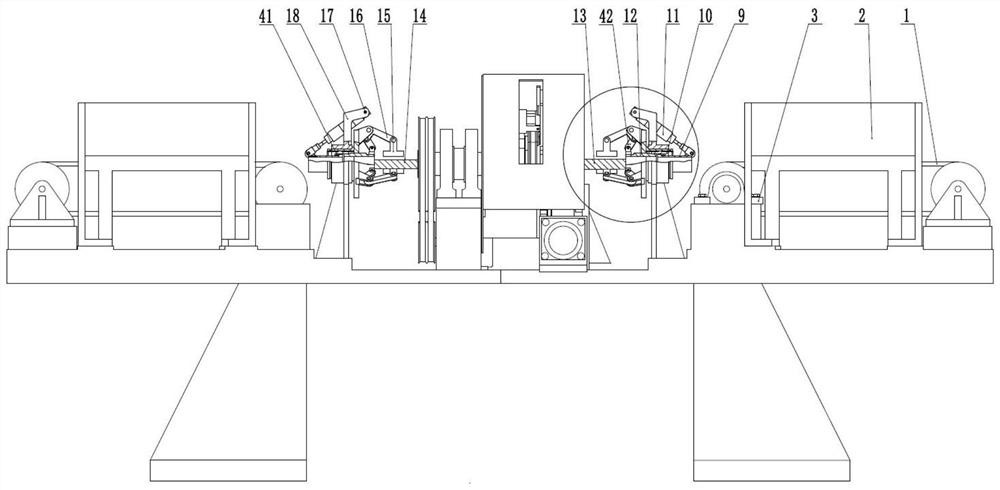

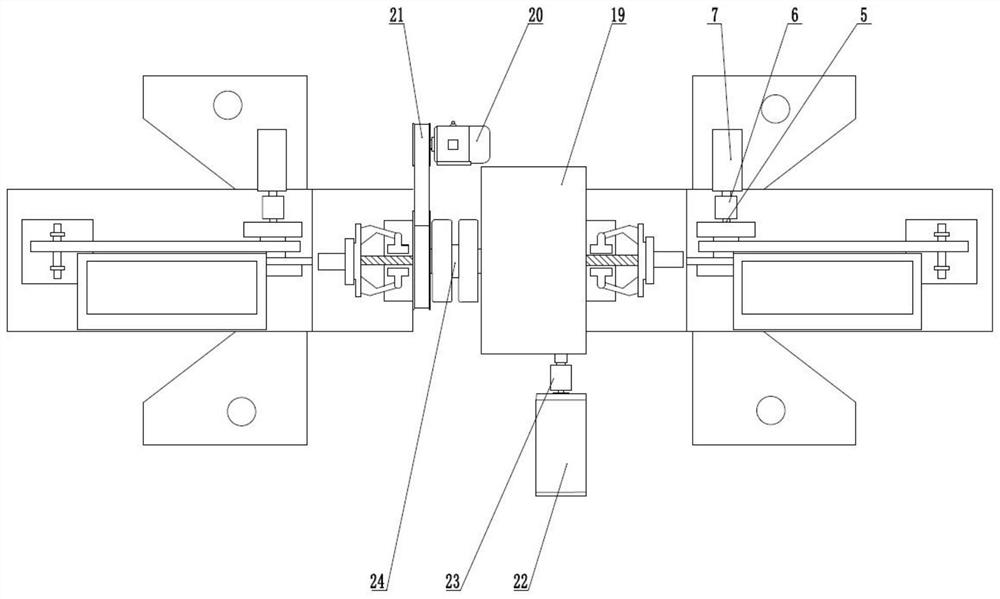

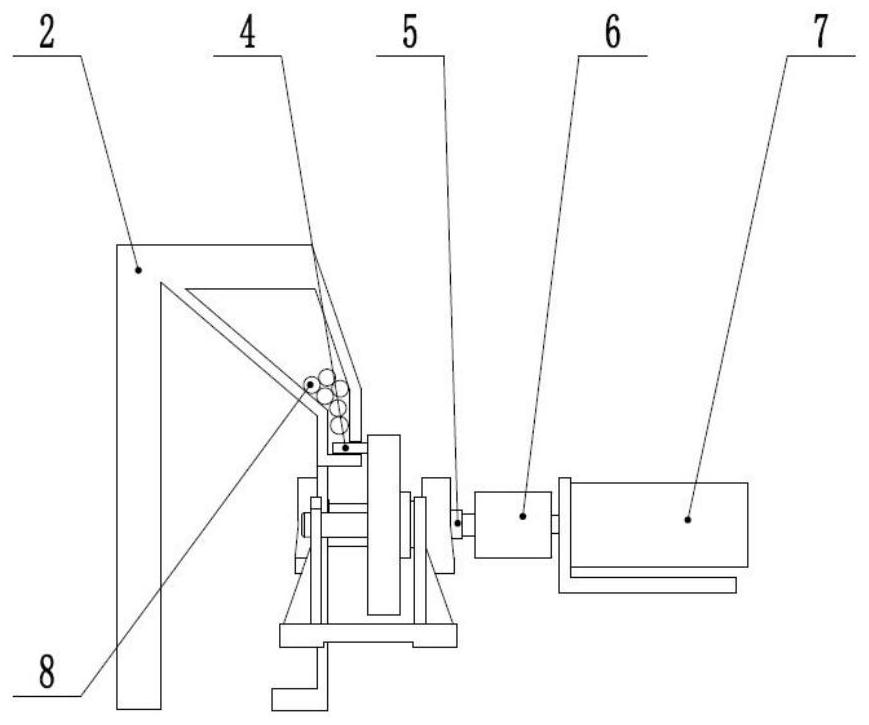

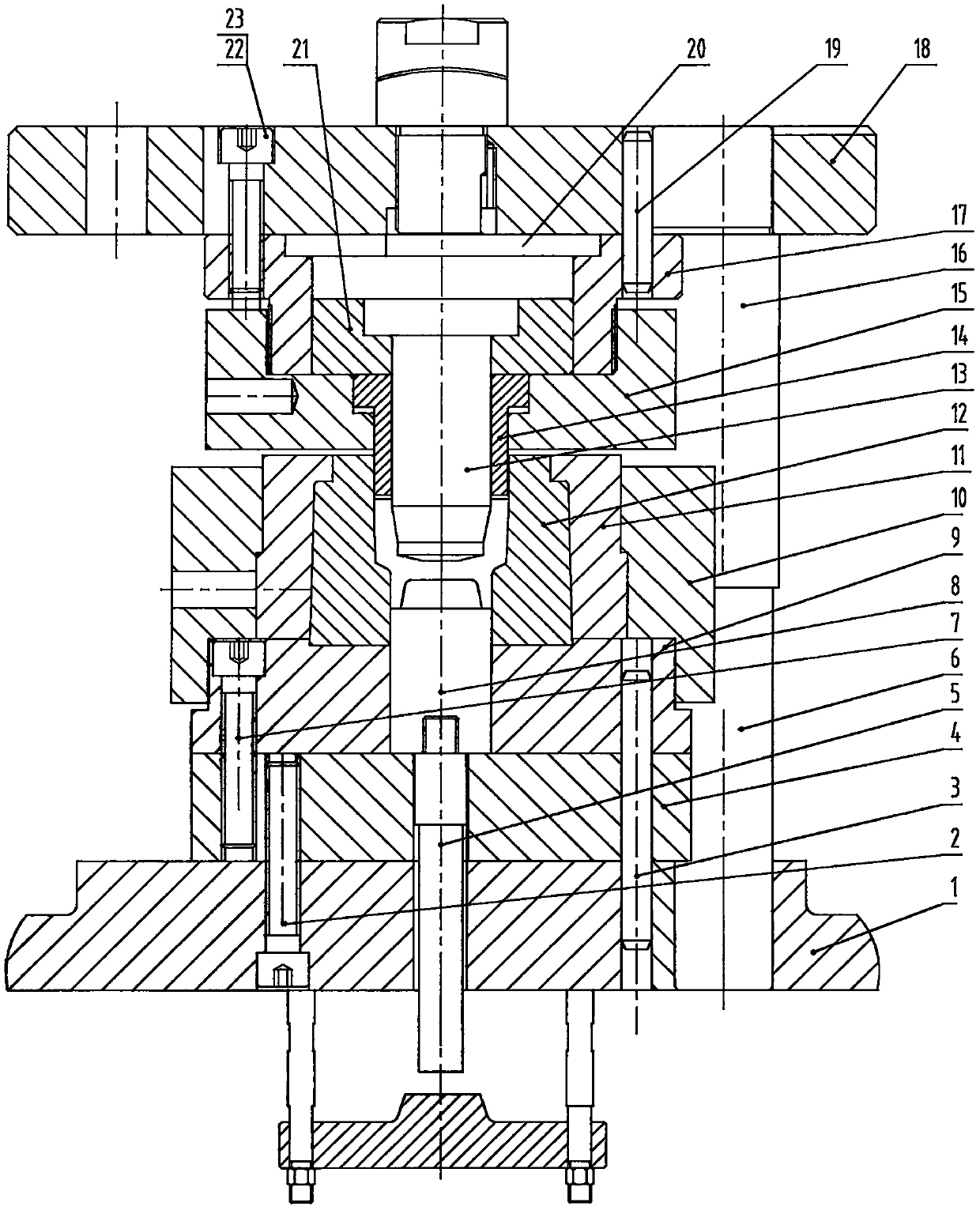

The invention relates to tubing handling apparatus for injecting tubing into and recovering the tubing from a wellbore. In an embodiment, the apparatus includes a storage reel of coiled tubing, a first injector head and a second injector head for injecting the tubing from the reel into the wellbore. The second injector head may be located between the storage reel and the wellbore, and the first injector head may be disposed between the storage reel and the second injector head. The first and second injector heads can control bending of a length of the coiled tubing from the reel which is passed between the first and second injector heads.

Owner:QSERV

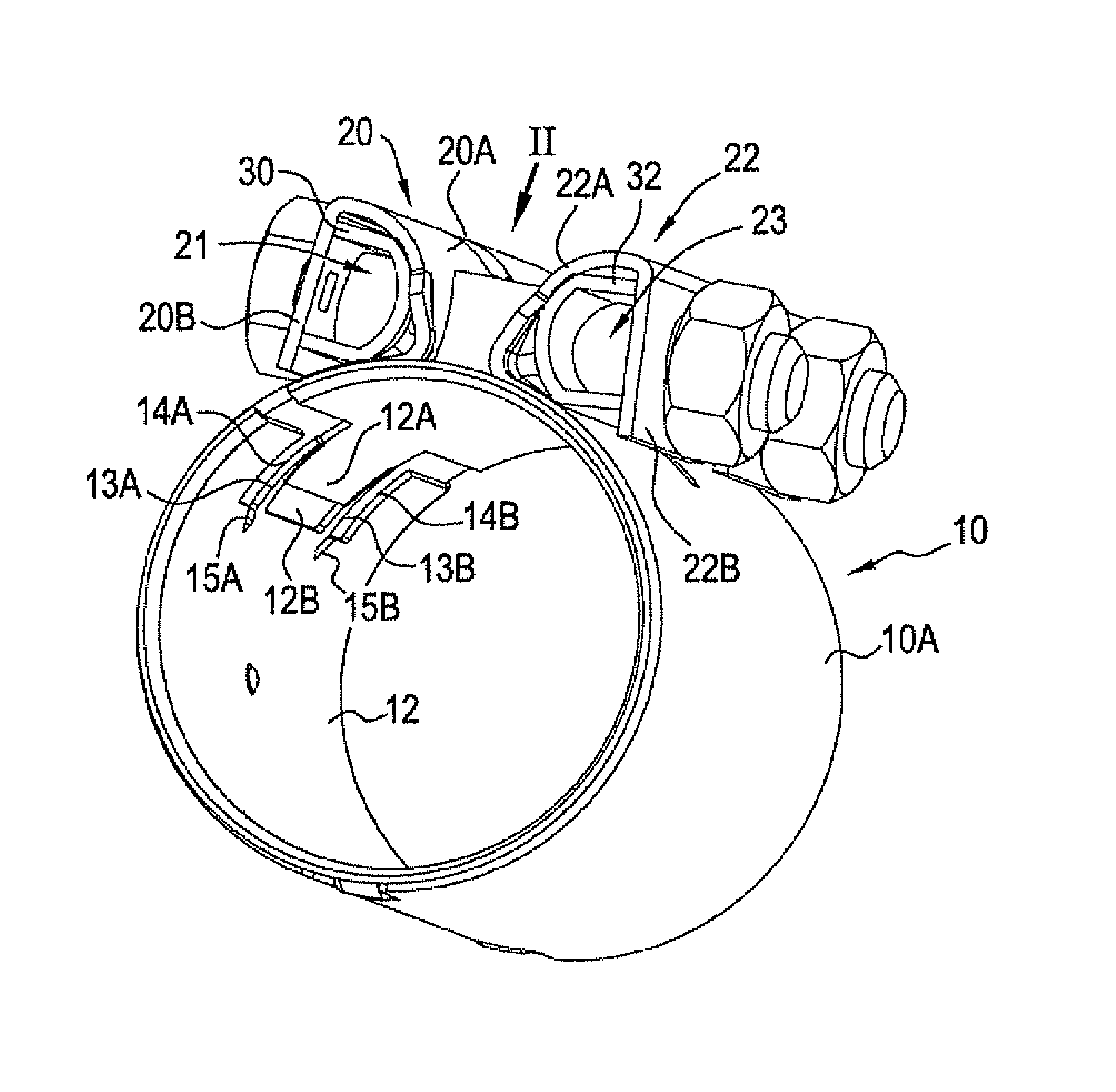

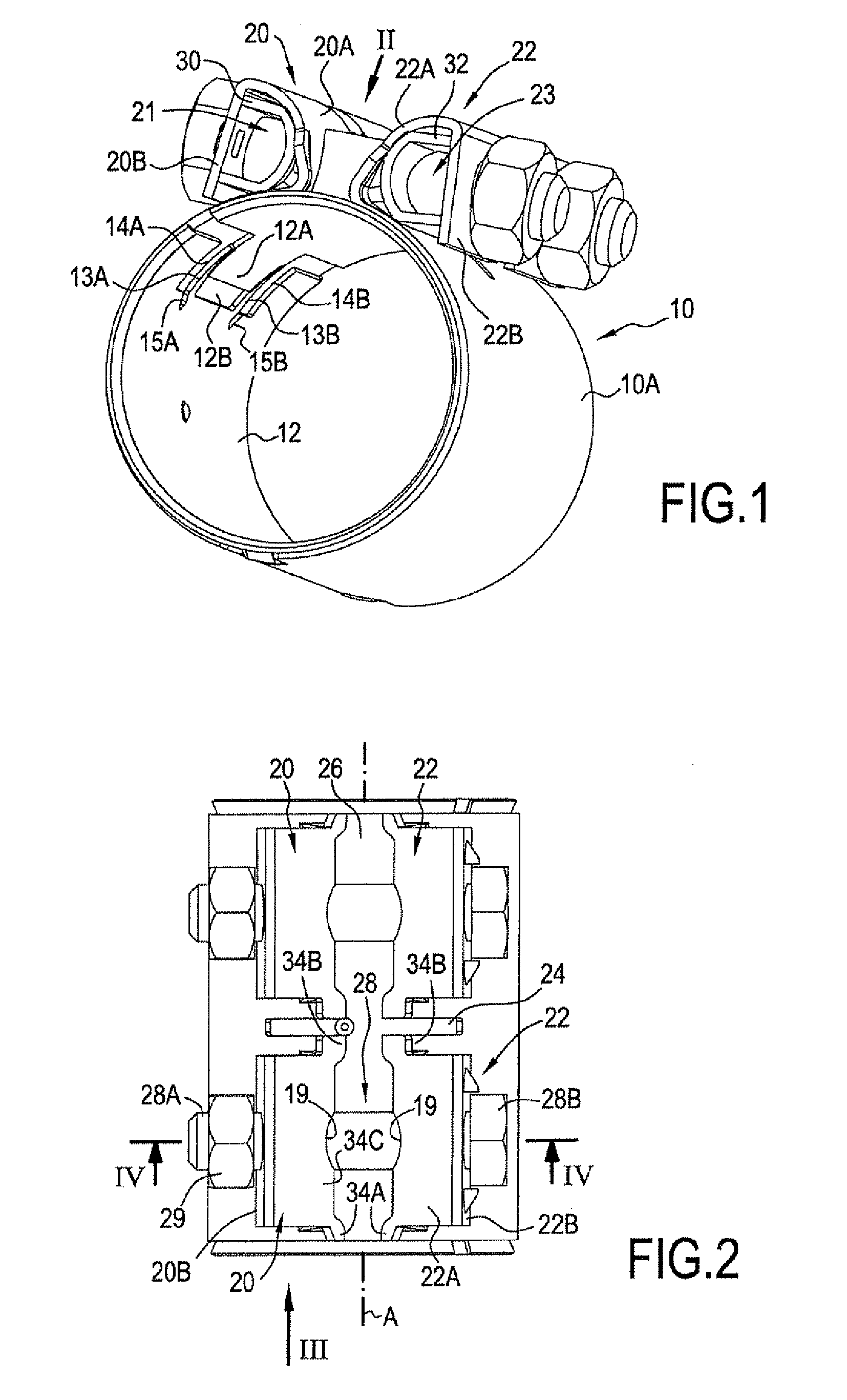

Clamping device with reinforced clamping lugs

ActiveUS8042234B2Facilitates good distribution of tightening forceReduce widthSnap fastenersSleeve/socket jointsEngineeringMechanical engineering

Owner:ESTAB CAILLAU SARL

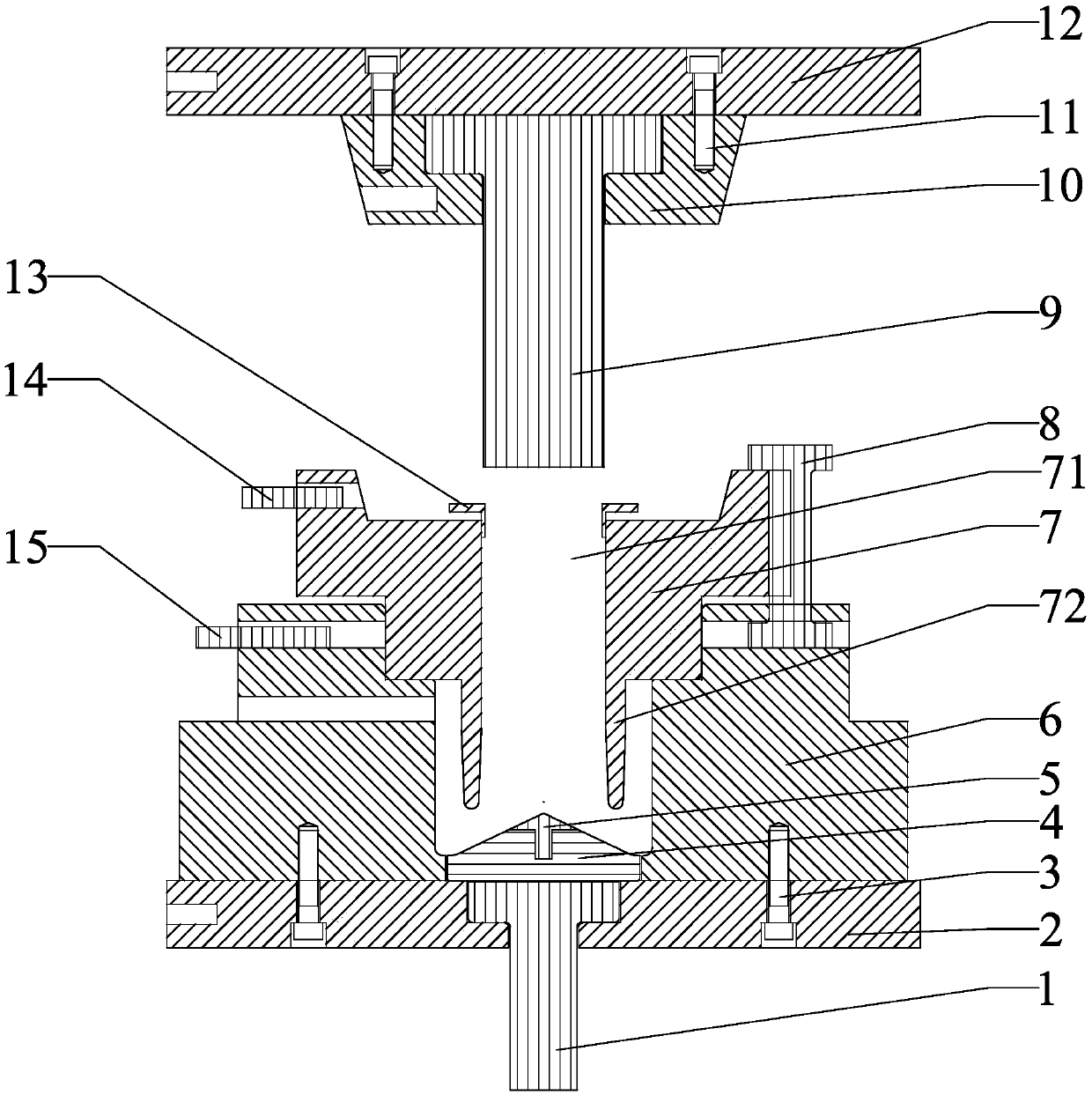

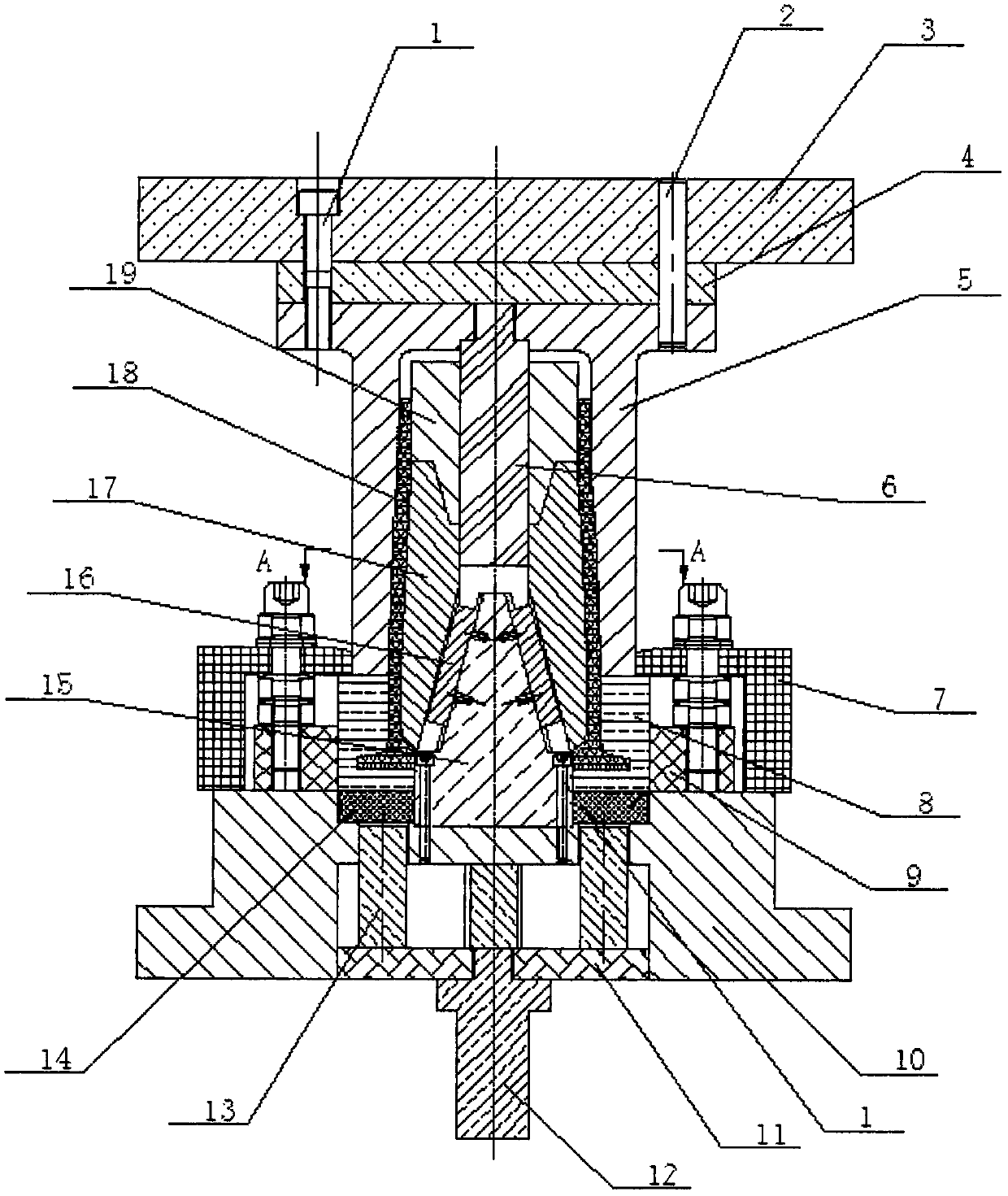

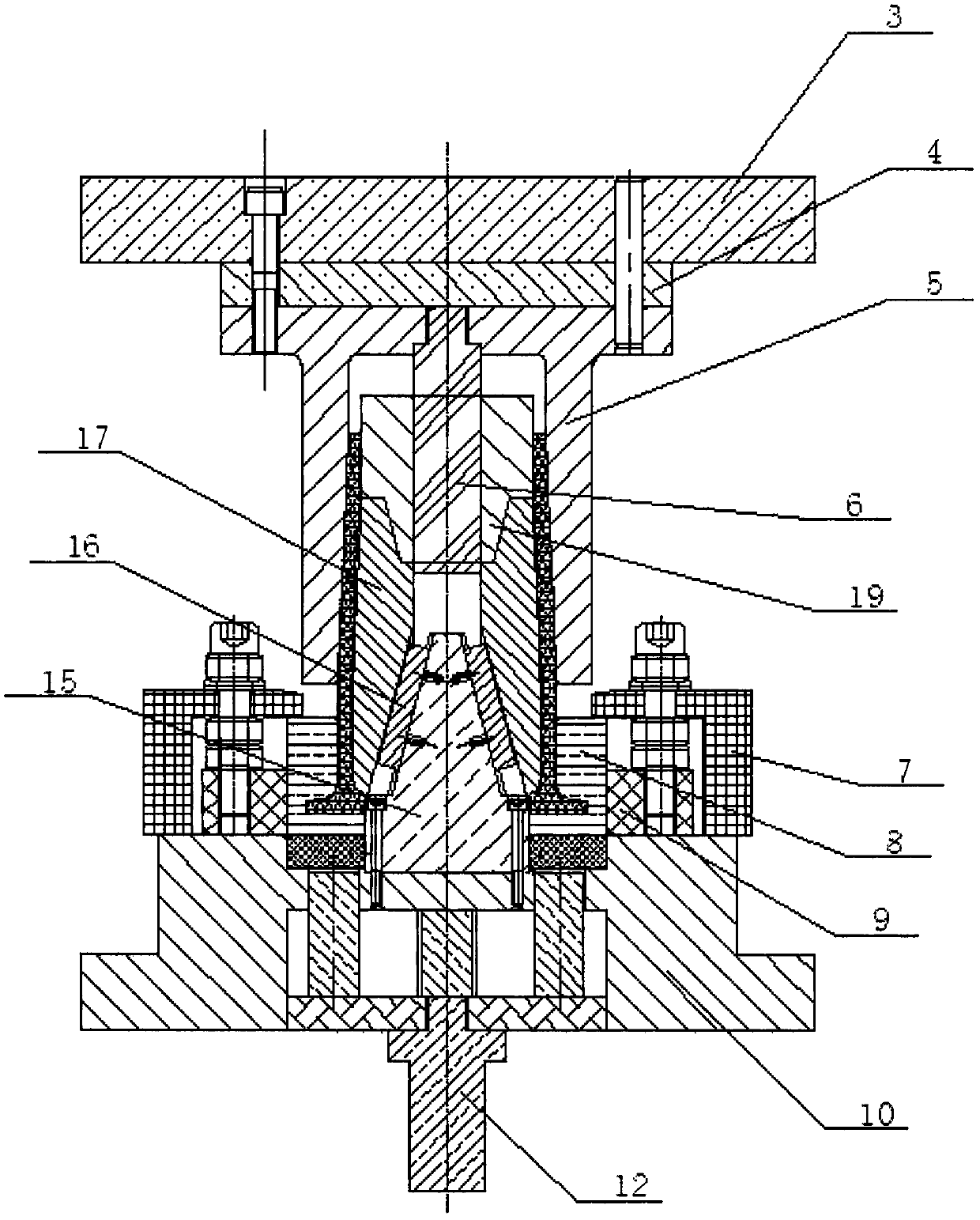

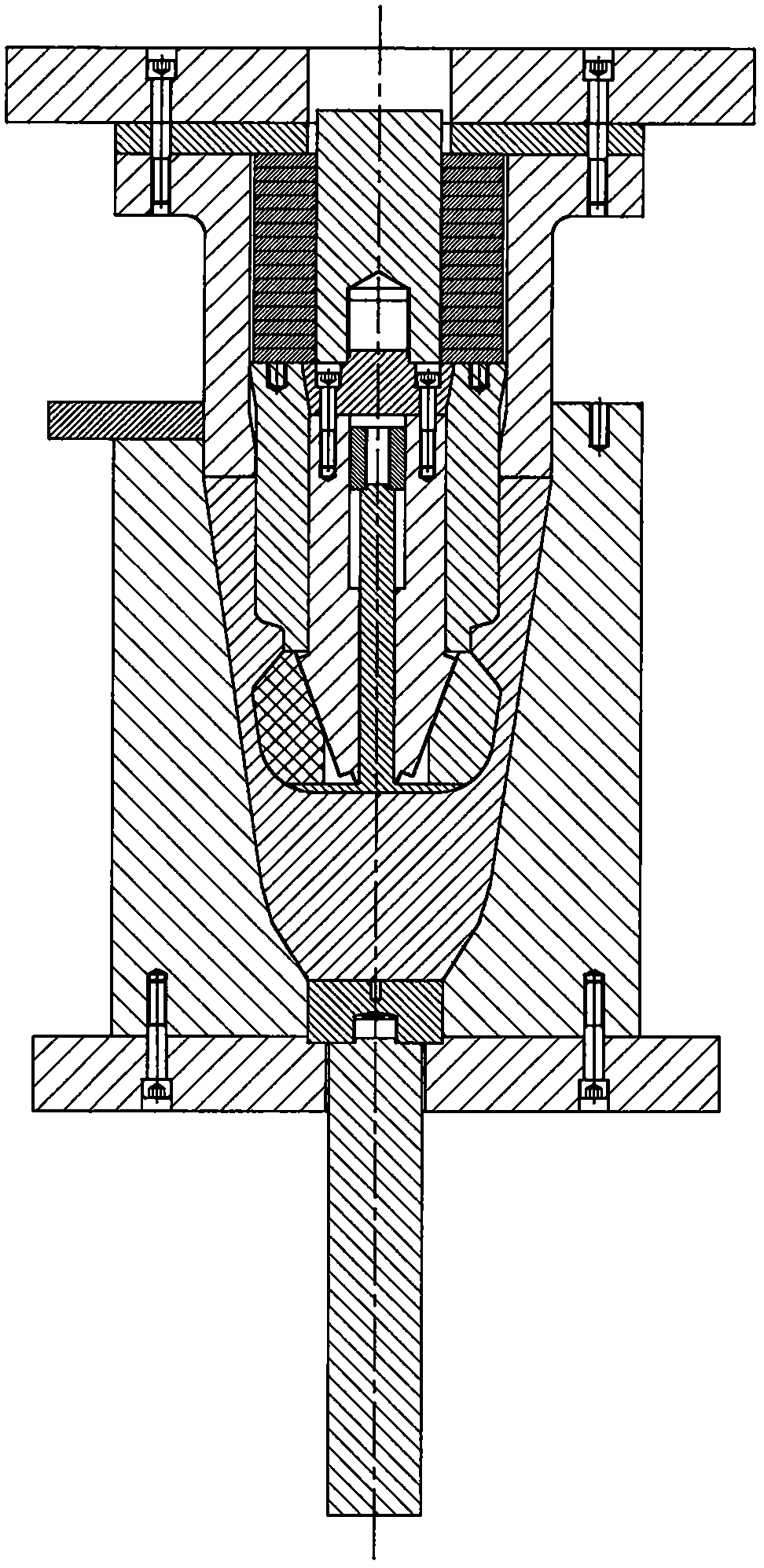

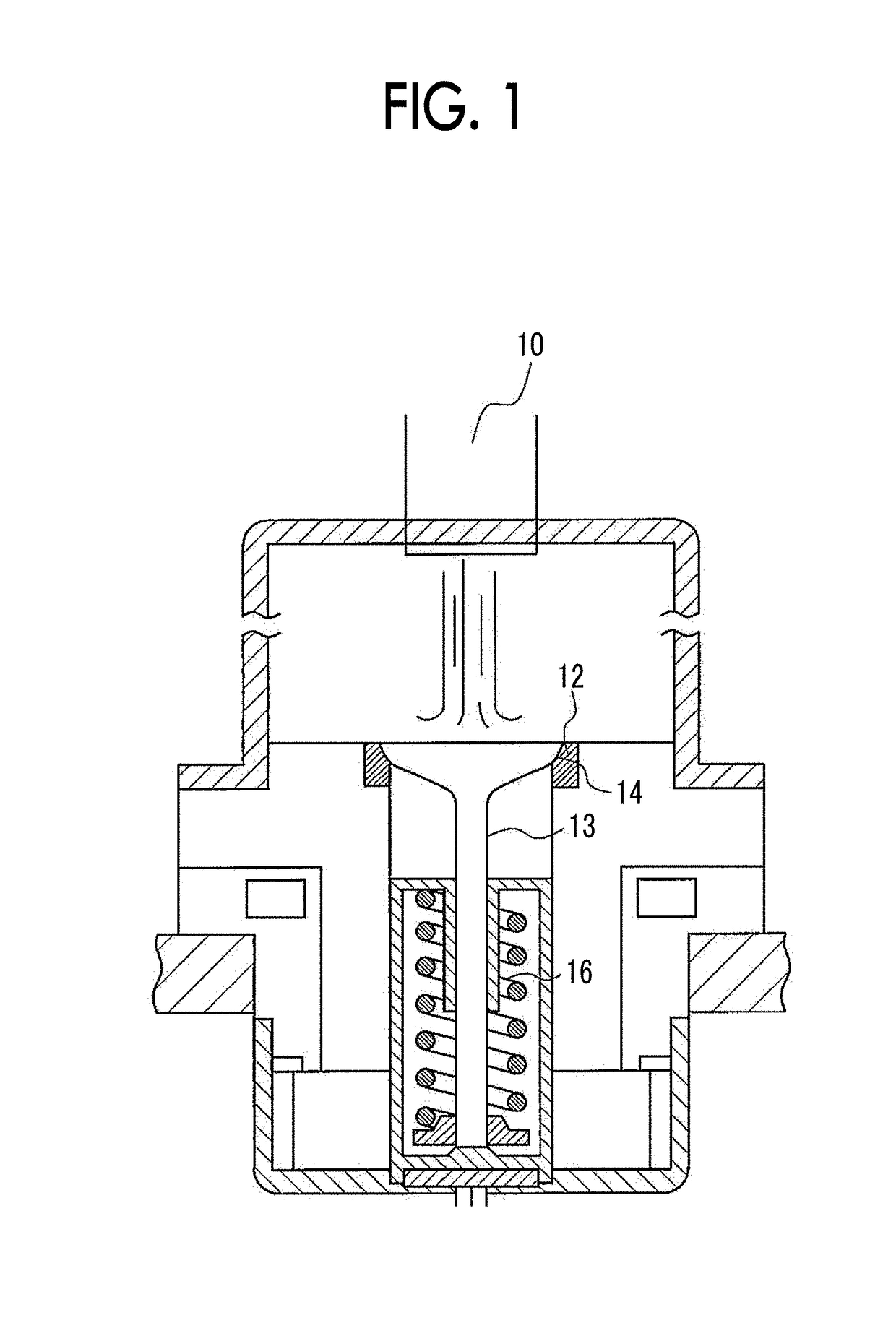

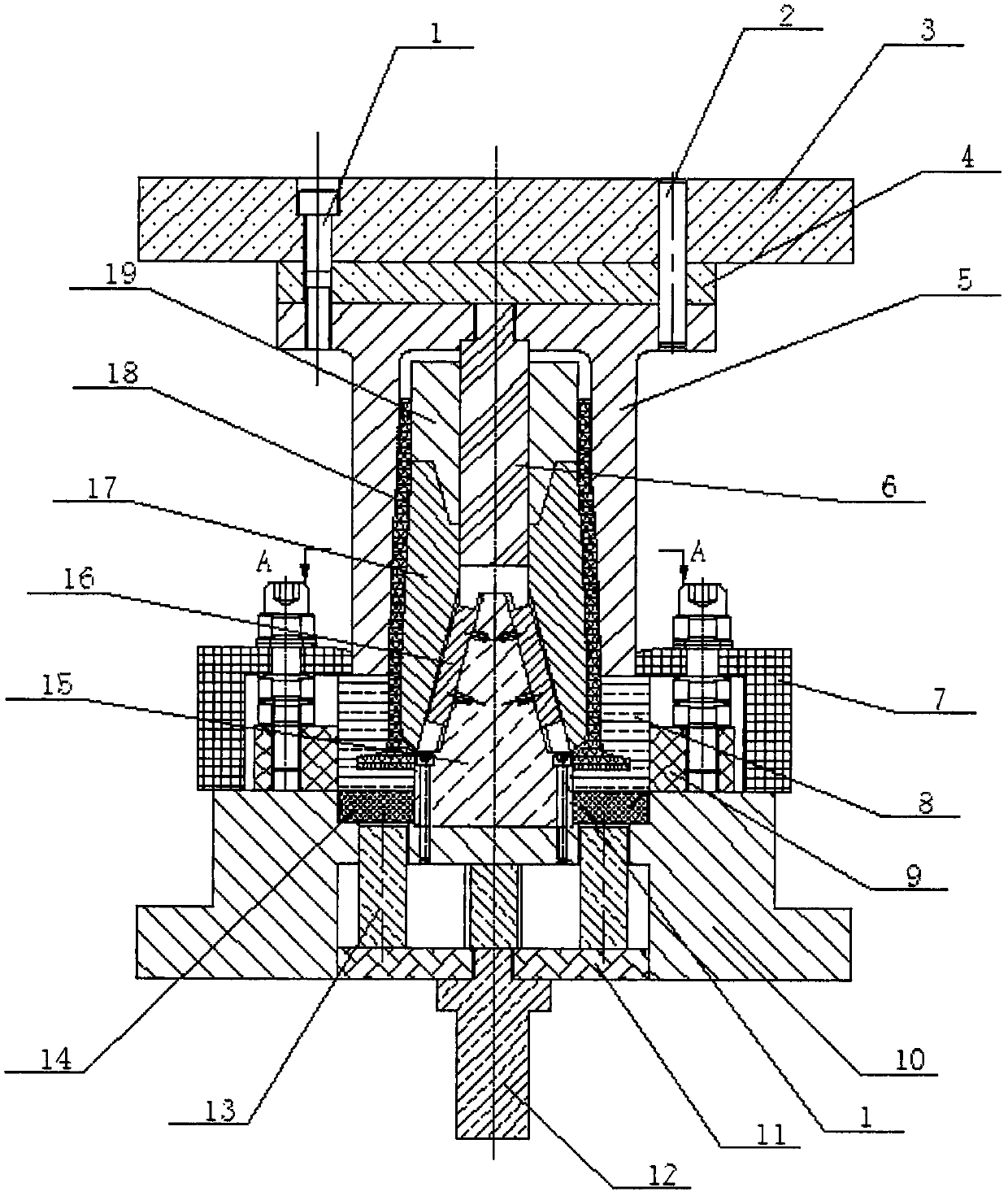

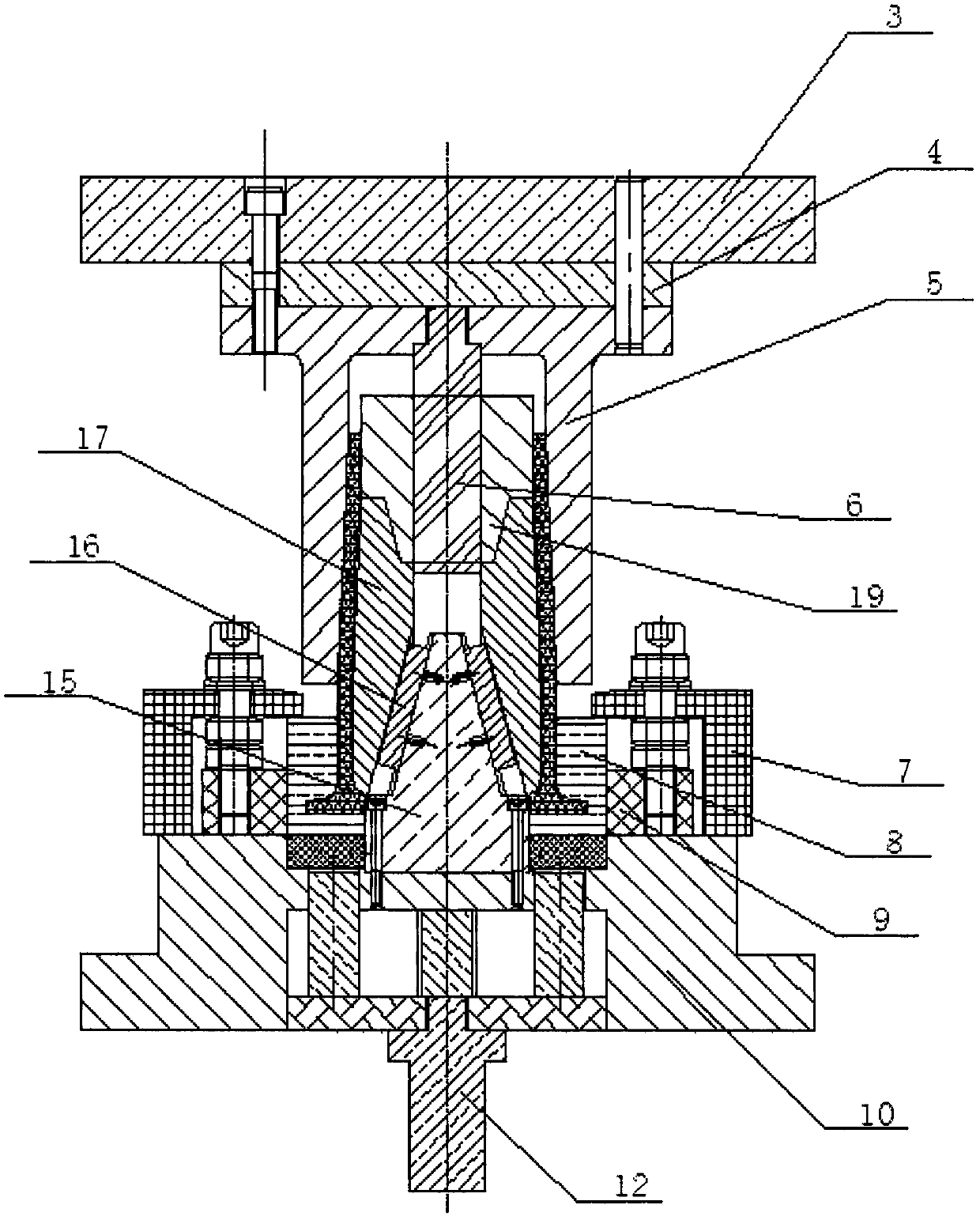

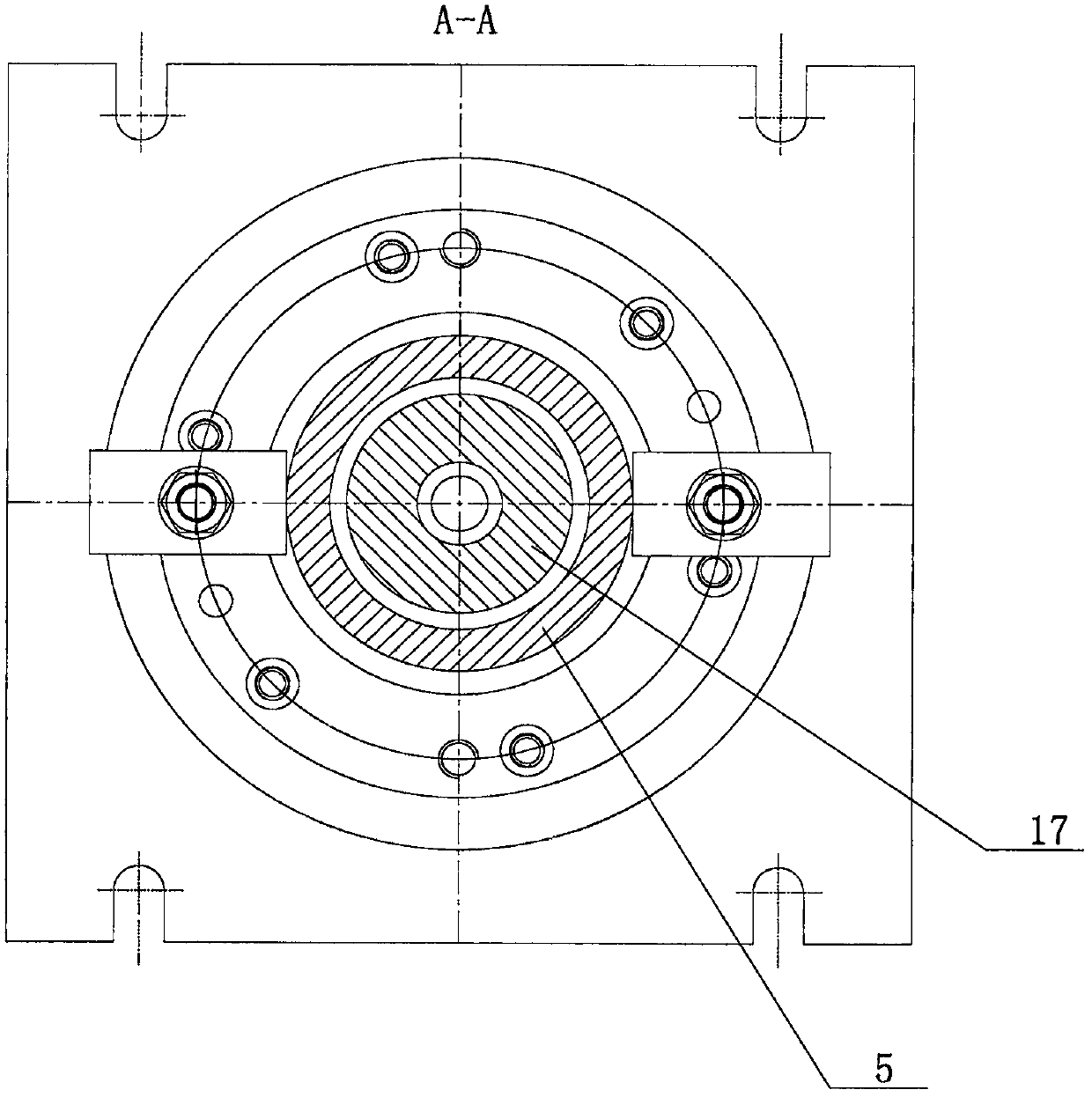

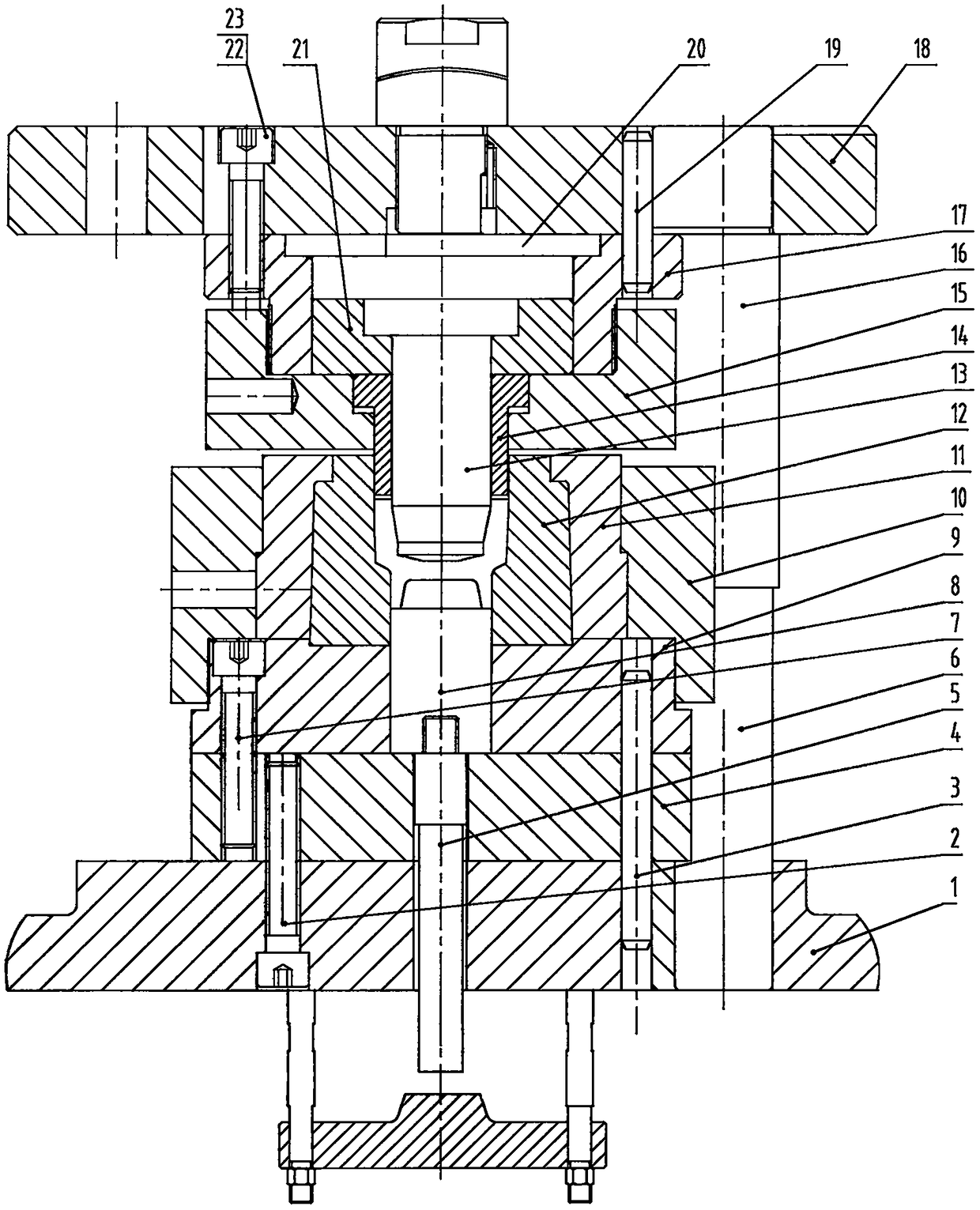

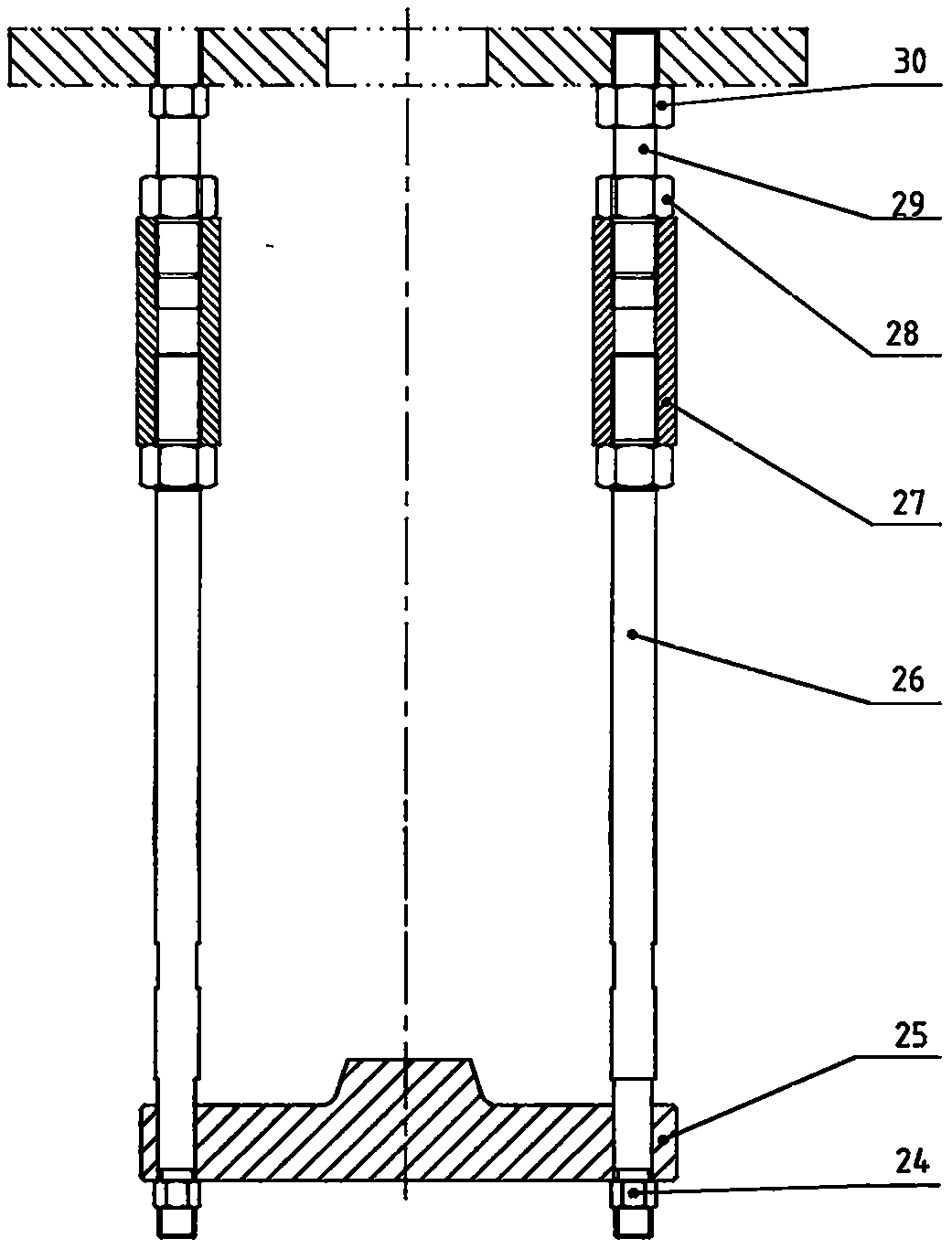

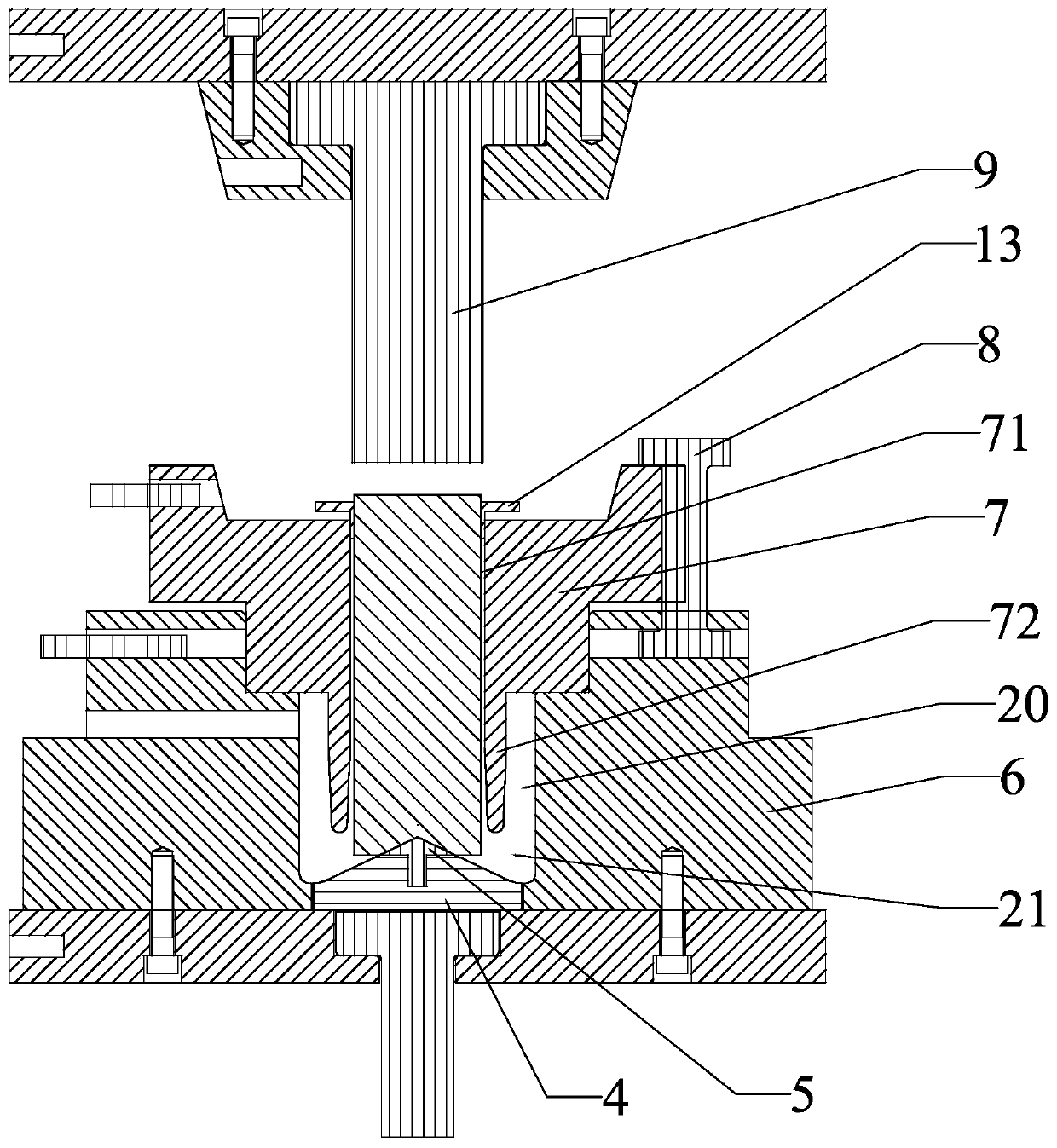

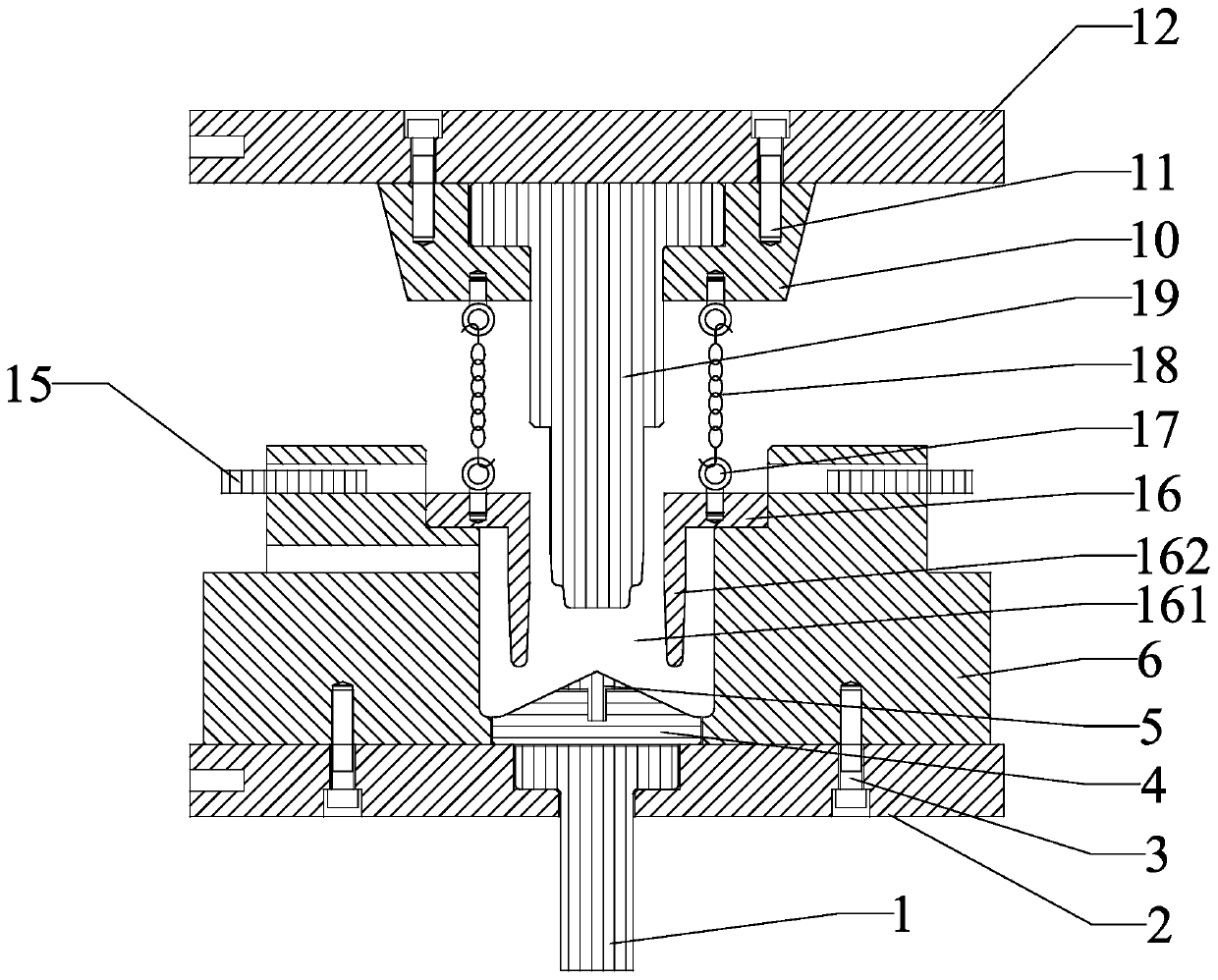

Extrusion forming die for thin-wall near-contoured chevron light alloy member

ActiveCN109530471AUniform wall thicknessDoes not affect separation distanceExtrusion diesAlloyMechanical property

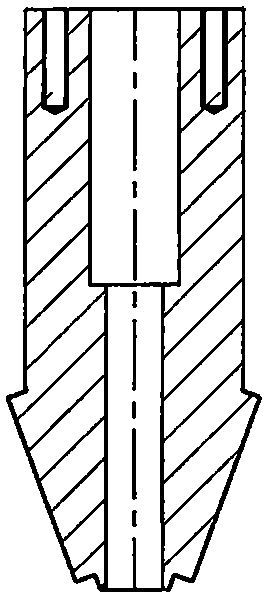

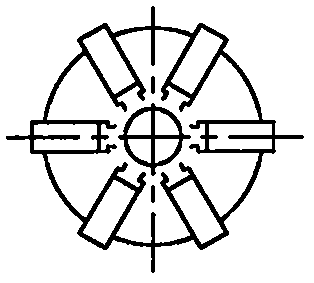

The invention discloses an extrusion forming die for a thin-wall near-contoured chevron light alloy member, which comprises an upper die component, a lower die component, an ejection device, a material ramming device, a fixed component and a movable component, wherein the upper die assembly comprises an upper die plate, a male die fixed ring, a first pass male die and a second pass male die, the first pass male die and the second pass male die are interchangeable, the lower die assembly comprises a lower template, a female die, a middle female die and a mandrel, the middle female die and the mandrel are interchangeable. When the upper die assembly is assembled with the first pass male die, the female die is correspondingly provided with the middle female die, a middle male die is providedwith a discharging channel, and a lower annular wall is extended out of the lower section of the discharging channel. The ejection device comprises an ejection block and an ejector rod. The material ramming device comprises a material ramming plate. The fixed component and the movable component comprise an umbrella cap, a cylindrical pin, a fixed block, a hanging erbium and a chain. According to the extrusion forming die for the thin-wall near-contoured chevron light alloy member, the precise plastic forming of the thin-wall near-contoured complex chevron member is achieved, the problems brought by the traditional processing and manufacturing die are effectively overcome, the formability of the light alloy is improved, the comprehensive mechanical property of the formed member is improved, the material utilization rate is greatly improved, the energy is saved and the consumption is reduced.

Owner:ZHONGBEI UNIV

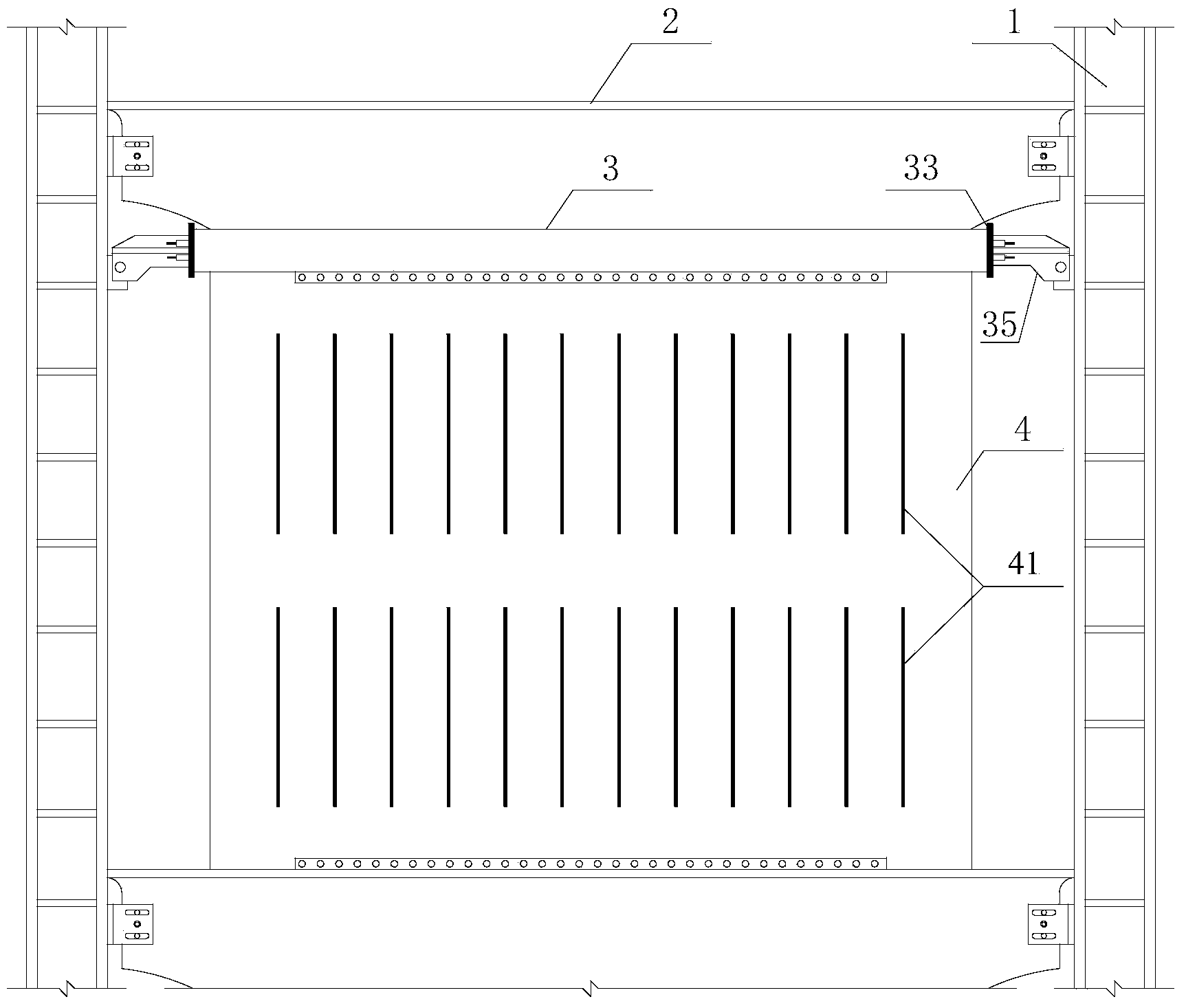

Post-tensioned prestressing self centering steel plate shear wall structure

InactiveCN103866882AEffective control of residual deformationStable and continuous elastic recoveryWallsShock proofingFloor slabEngineering structures

The invention discloses a post-tensioned prestressing self centering steel plate shear wall structure, which comprises at least one structural unit, wherein the structural unit comprises two steel framework posts, a T-shaped steel beam, a self centering connecting element and a steel plate shear wall, wherein the T-shaped steel beam is connected with the upper ends of the two steel framework posts, the self centering connecting element is positioned at the lower side of the T-shaped steel beam and is connected with the two steel framework posts, the steel plate shear wall is positioned under the self centering connecting element, the self centering connecting element comprises an inner sleeve pipe, an outer sleeve pipe, an end plate, a pre-stretching rod and a connecting head, the inner sleeve pipe is sheathed by the outer sleeve pipe, the end plate seals the end parts of the inner sleeve pipe and the outer sleeve pipe, the pre-stretching rod is arranged in the inner sleeve pipe and is anchored on the end plate, the connecting head is connected with the end part of the inner sleeve pipe, the length of the upper wing edge of the T-shaped steel beam is greater than the length a the web plate, the lower end of the web plate of the T-shaped steel beam is connected with the upper side surface of the outer sleeve pipe, and the lower side surface of the outer sleeve pipe is connected with the upper side surface of the steel plate shear wall. The post-tensioned prestressing self centering steel plate shear wall structure has the advantages that the plastic deformation of the steel plate shear wall can be effectively eliminated, the lateral deformation coordination of a framework and a floor slab can be ensured, and the restoring cost and the restoring difficulty of the engineering structures after the earthquake are greatly reduced.

Owner:SOUTHEAST UNIV

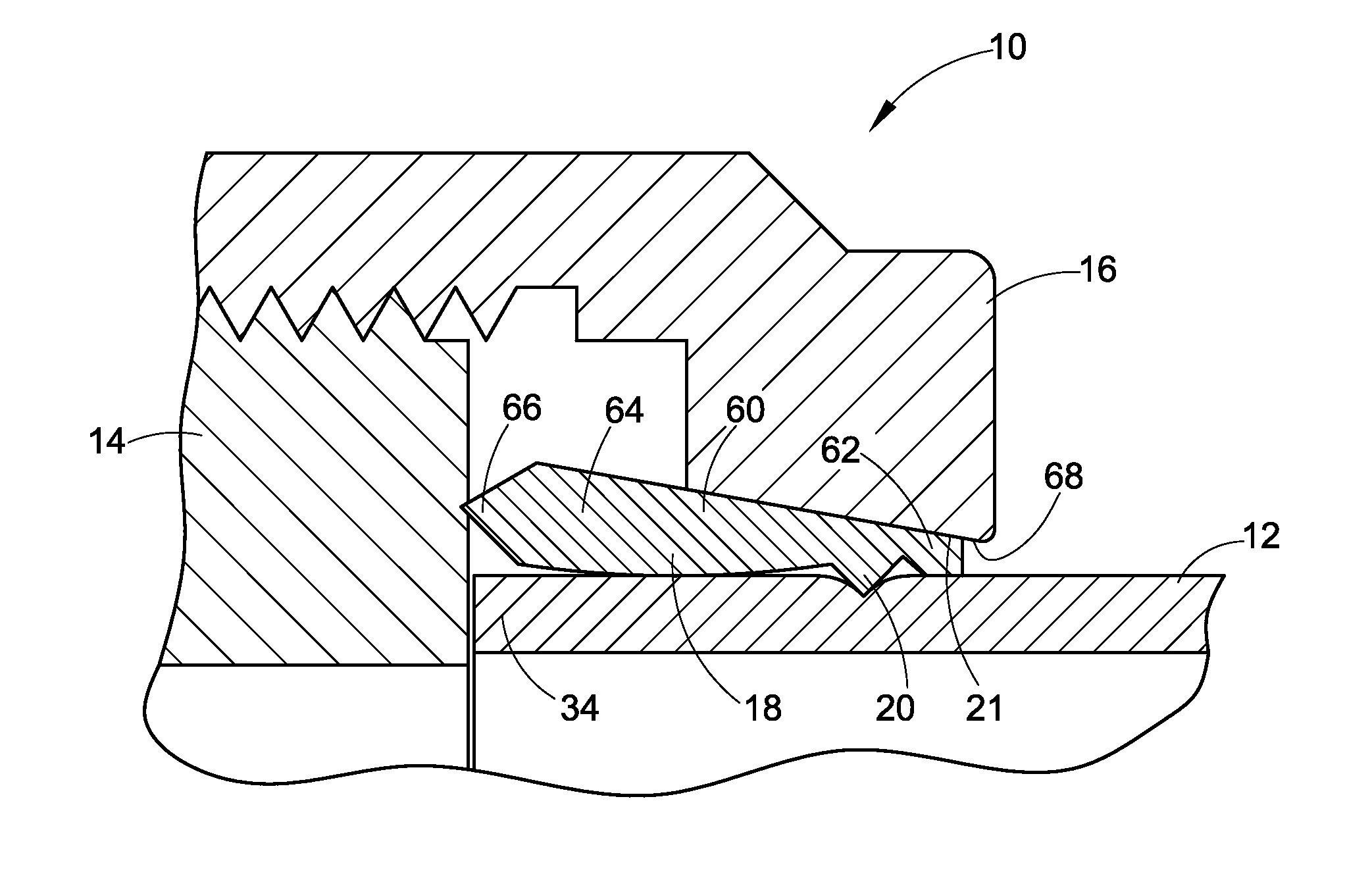

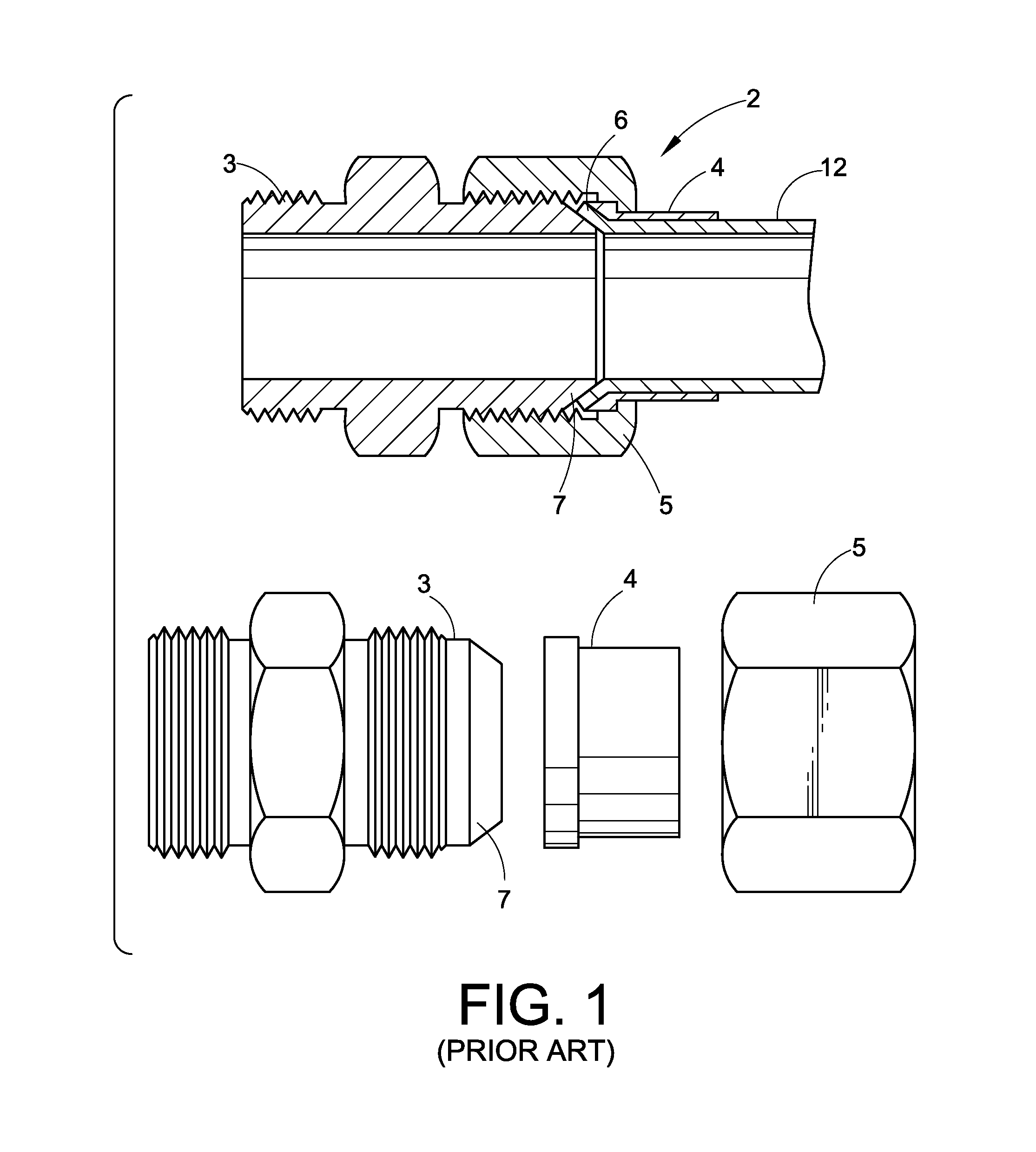

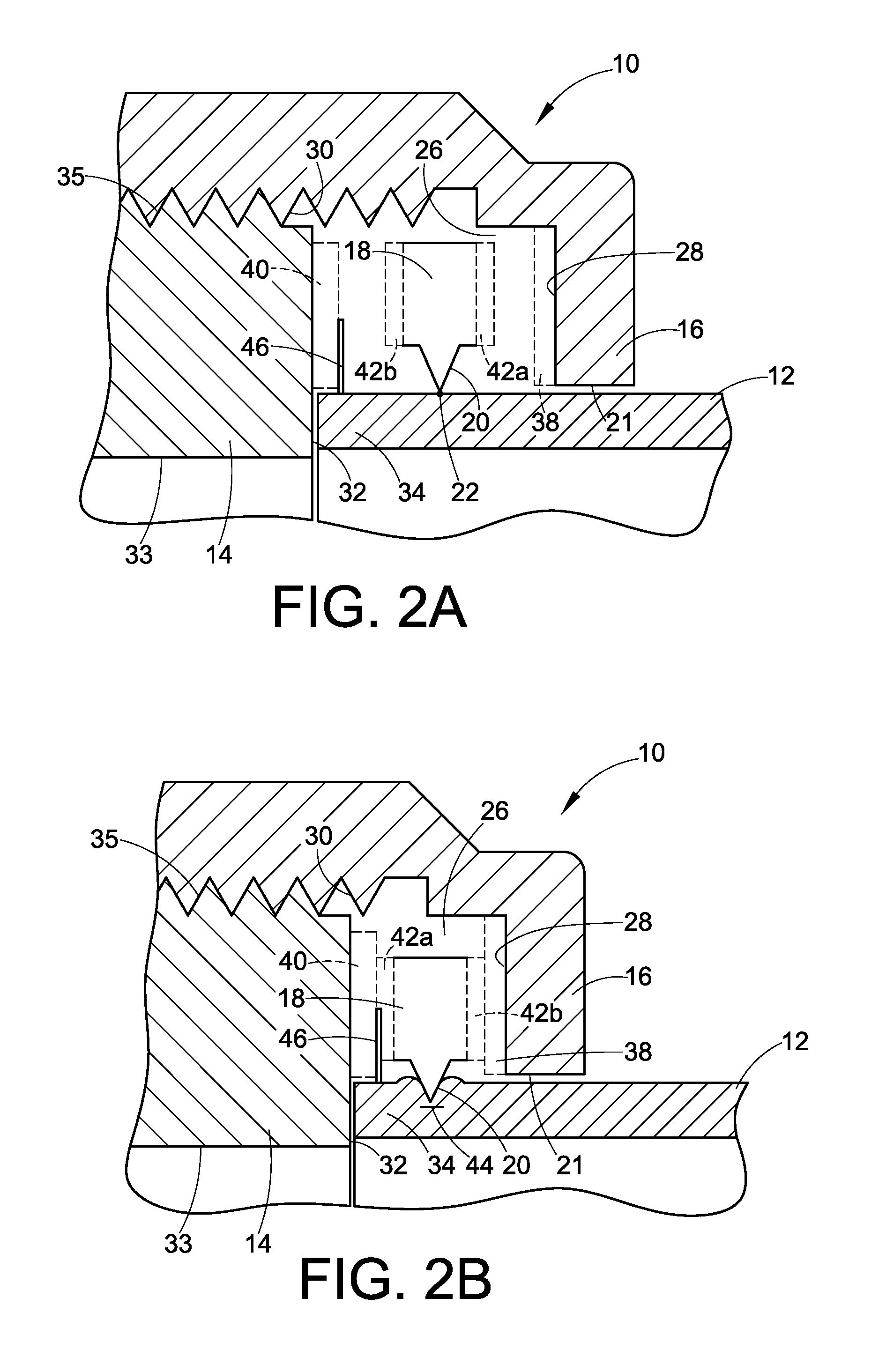

Tube fitting

InactiveUS20120187678A1Little strengthDeformation MinimizationSleeve/socket jointsFluid pressure sealed jointsEngineeringMechanical engineering

Owner:SWAGELOK CO

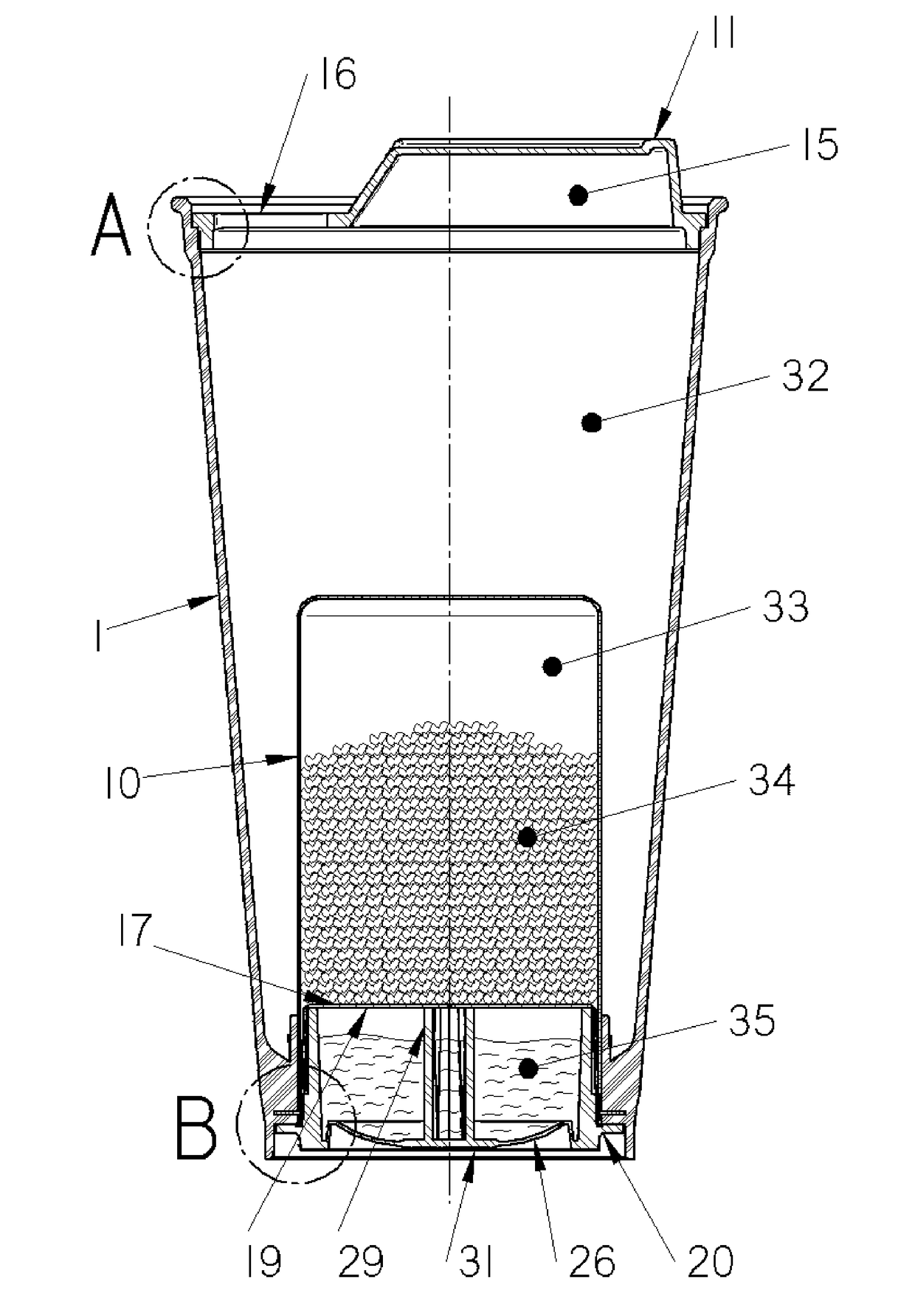

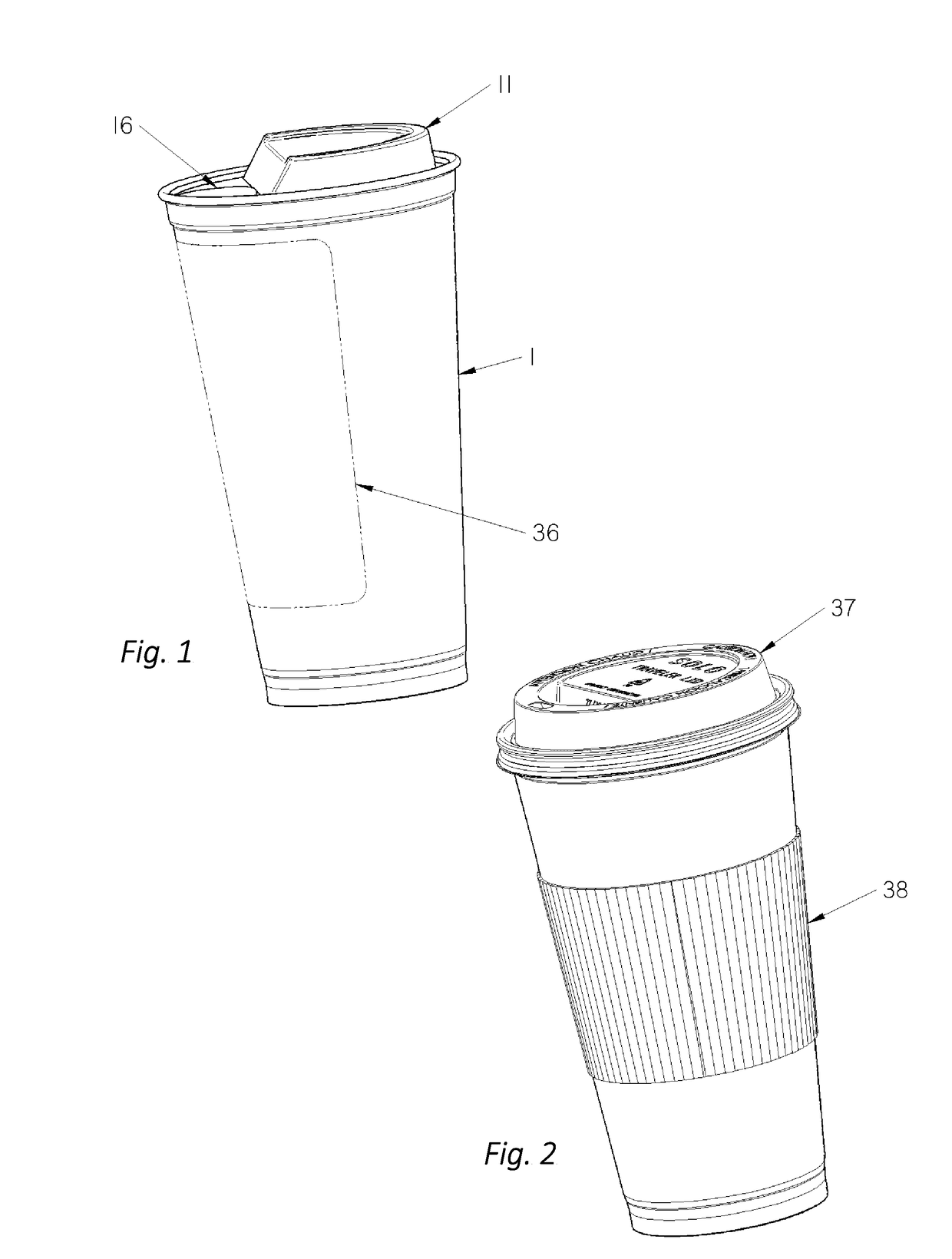

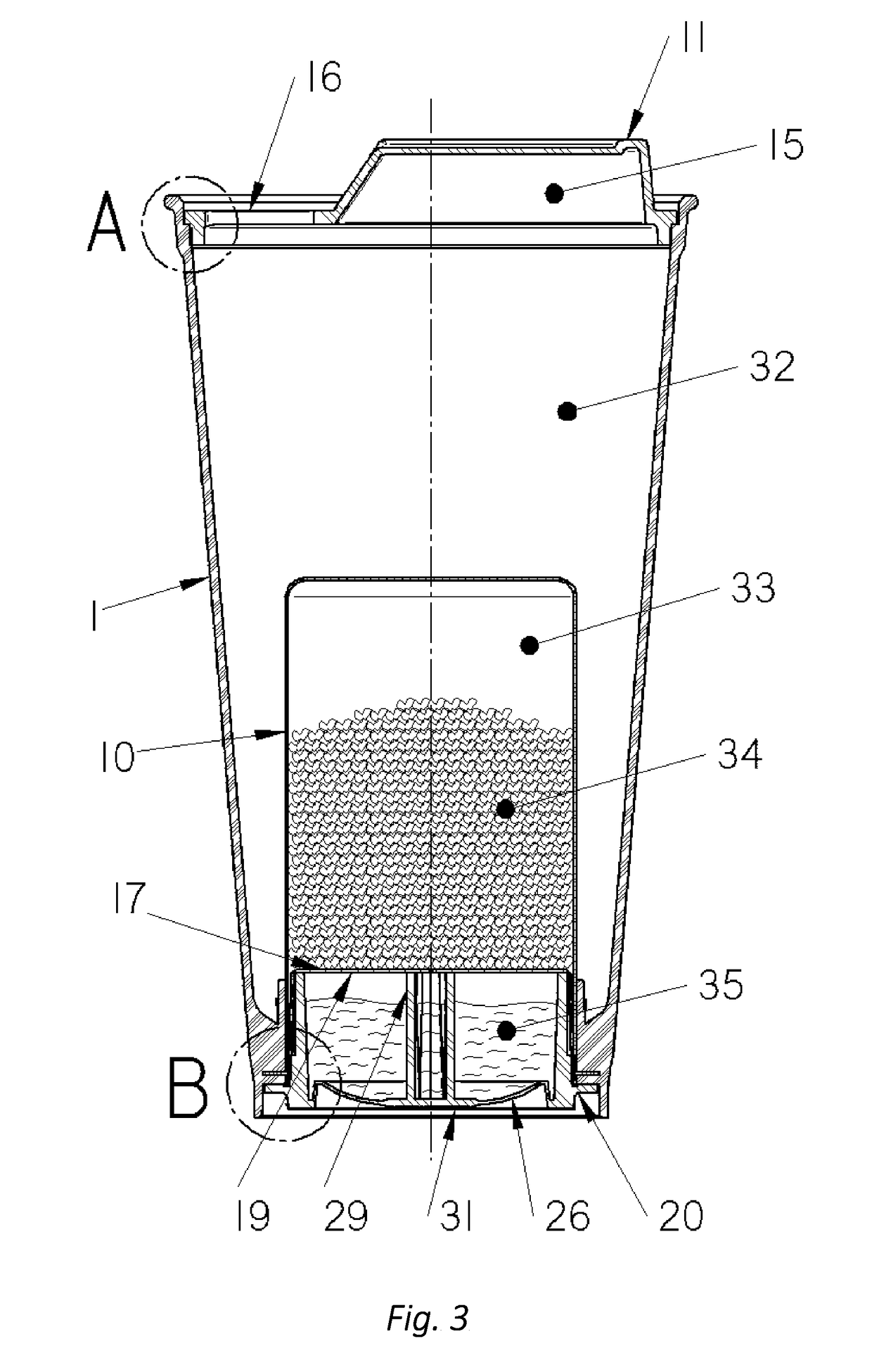

Single use self-heating cup

InactiveUS20180029777A1Improve heat transfer performanceWell formedClosuresContainers for heating foodComputer moduleEngineering

A large self-heating cup having an injected plastic container body (1) with two cavities, separated by a central overmolded metal wall (10). The upper cavity (32) contains the beverage while the lower cavity (33) is used to contain the heating module, an exothermic reaction without toxic reactants. Said lower cavity (33) is closed by a plastic base (20) which is also used to divide this cavity into two chambers by the way of a breakable seal (19). A solid reactant (34) is placed above the breakable seal (19) and a liquid reactant (35) is inside the plastic base (20). With the cup in an upside-down position, the user pulls off a protective foil (31) and pushes the actuator (26) which pierces the breakable seal (19) causing the mixing of both reactants and thus generate heat. An effective heat transfer to the beverage is possible by way of the separating metal wall (10) allowing a quickly elevation of its temperature.A special coating on plastics and a reinforced design authorizing a sterilization stage. The conical outer shape (1) is compliant with standard accessories like lids and paper sleeves to increase tasting comfort.

Owner:DUHAMEL CEDRIC JEAN

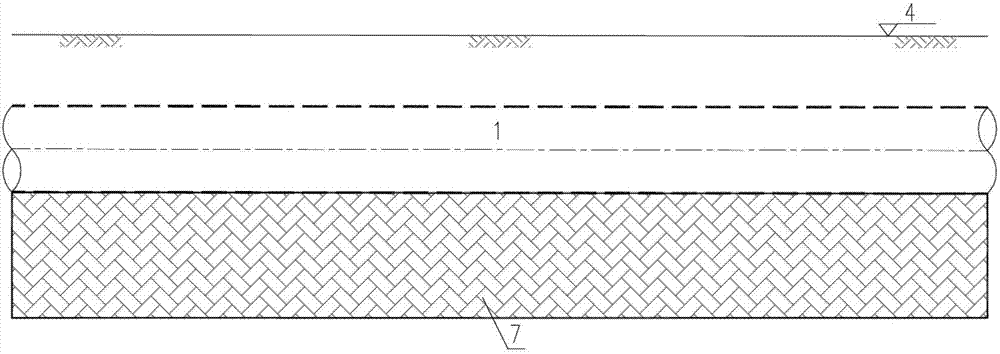

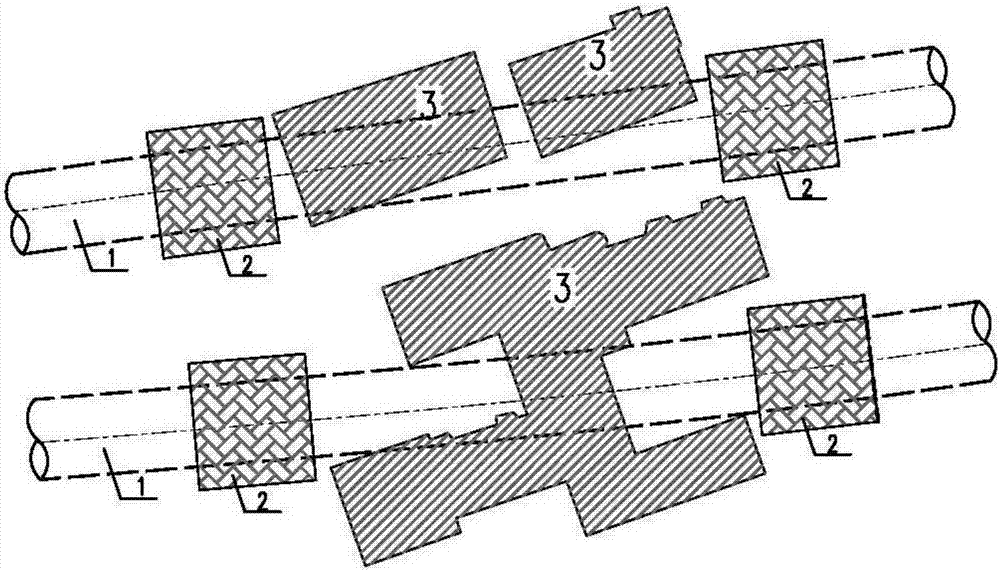

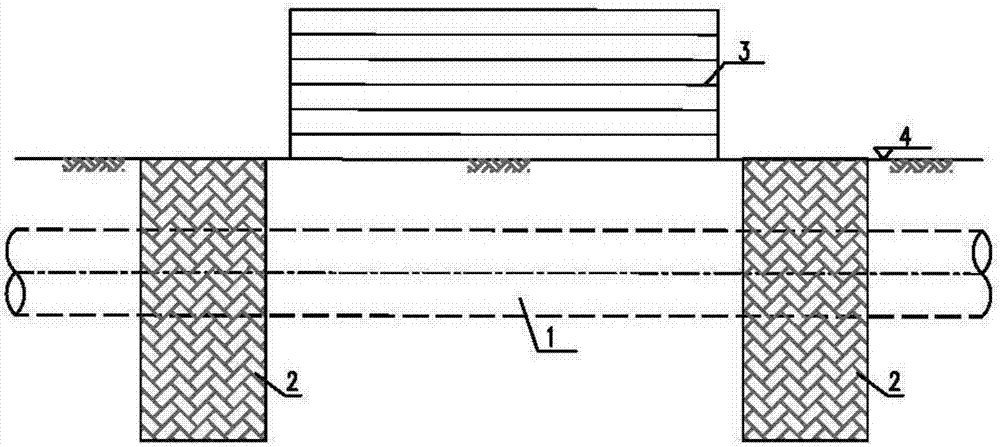

Control method and structure for shield tunnel underlying soft soil layer plastic deformation

PendingCN107100629AGuaranteed deformation requirementsGuaranteed stress requirementsTunnelsStructural engineeringShield tunnelling

The invention discloses a control method and structure for shield tunnel underlying soft soil layer plastic deformation. The control method and structure for the shield tunnel underlying soft soil layer plastic deformation are suitable for a shield tunnel of underneath pass buildings / structures. The control method includes the following steps that a soft soil layer within a certain depth range is reinforced on the spaces at the two ends of the underneath pass buildings / structures so as to form soil bearing platform support structures, and the shield tunnel penetrates through the soil bearing platform support structures at the two ends; and support for bearing loads is achieved by utilizing the shield tunnel structure and an underground bridge span type anti-sedimentation structure formed by the soil bearing platform support structures at the two ends, so that plastic deformation of a tunnel underlying soft soil layer is controlled. The invention further discloses a corresponding control structure for the shield tunnel underlying soft soil layer plastic deformation. According to the control method and structure for shield tunnel underlying soft soil layer plastic deformation, through optimized reinforcement way design, the plastic deformation of the underlying soft soil layer is controlled, and the control method and structure cannot damage the tunnel structure and are especially suitable for the shield tunnel of the underneath pass buildings / structures.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

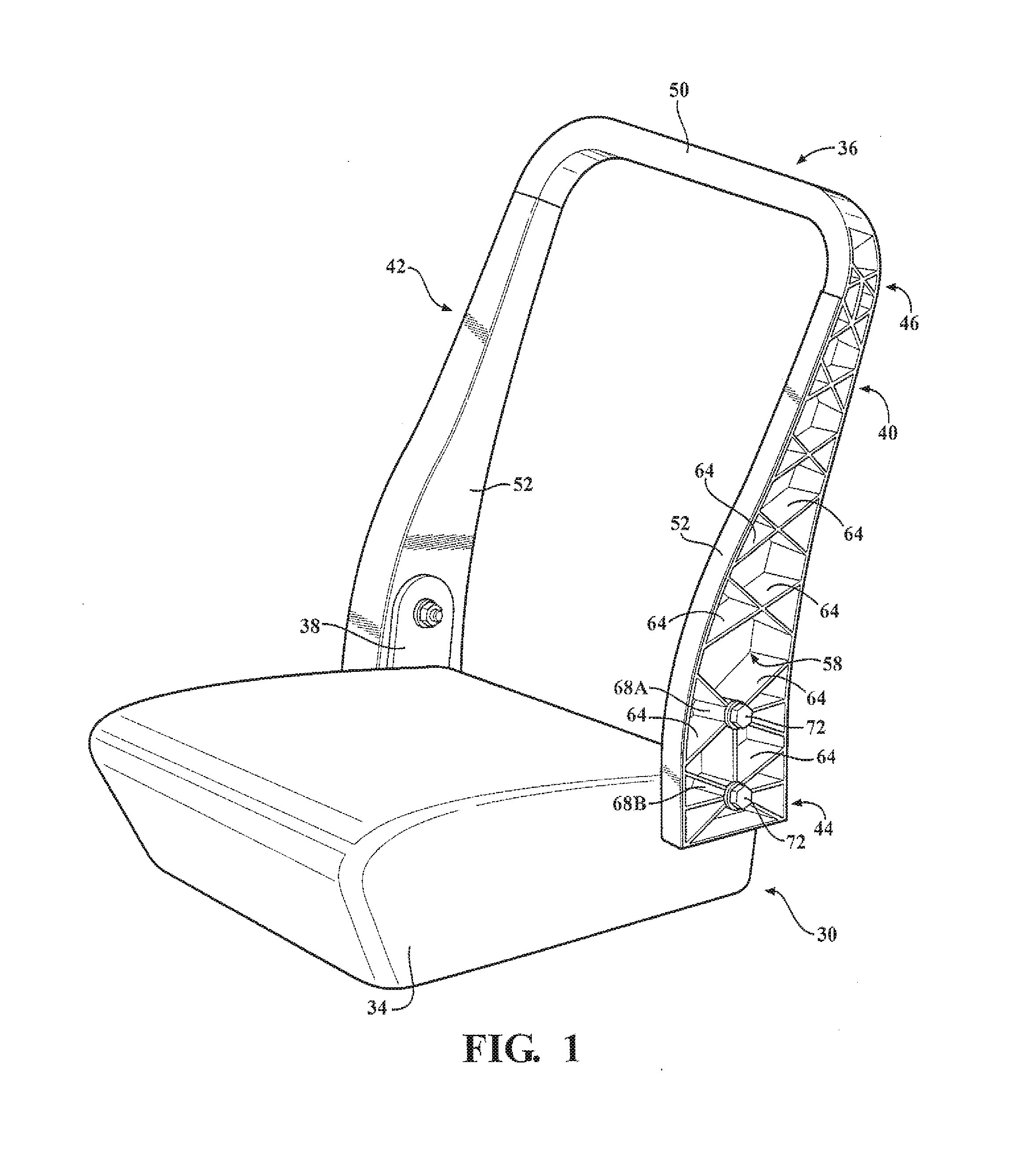

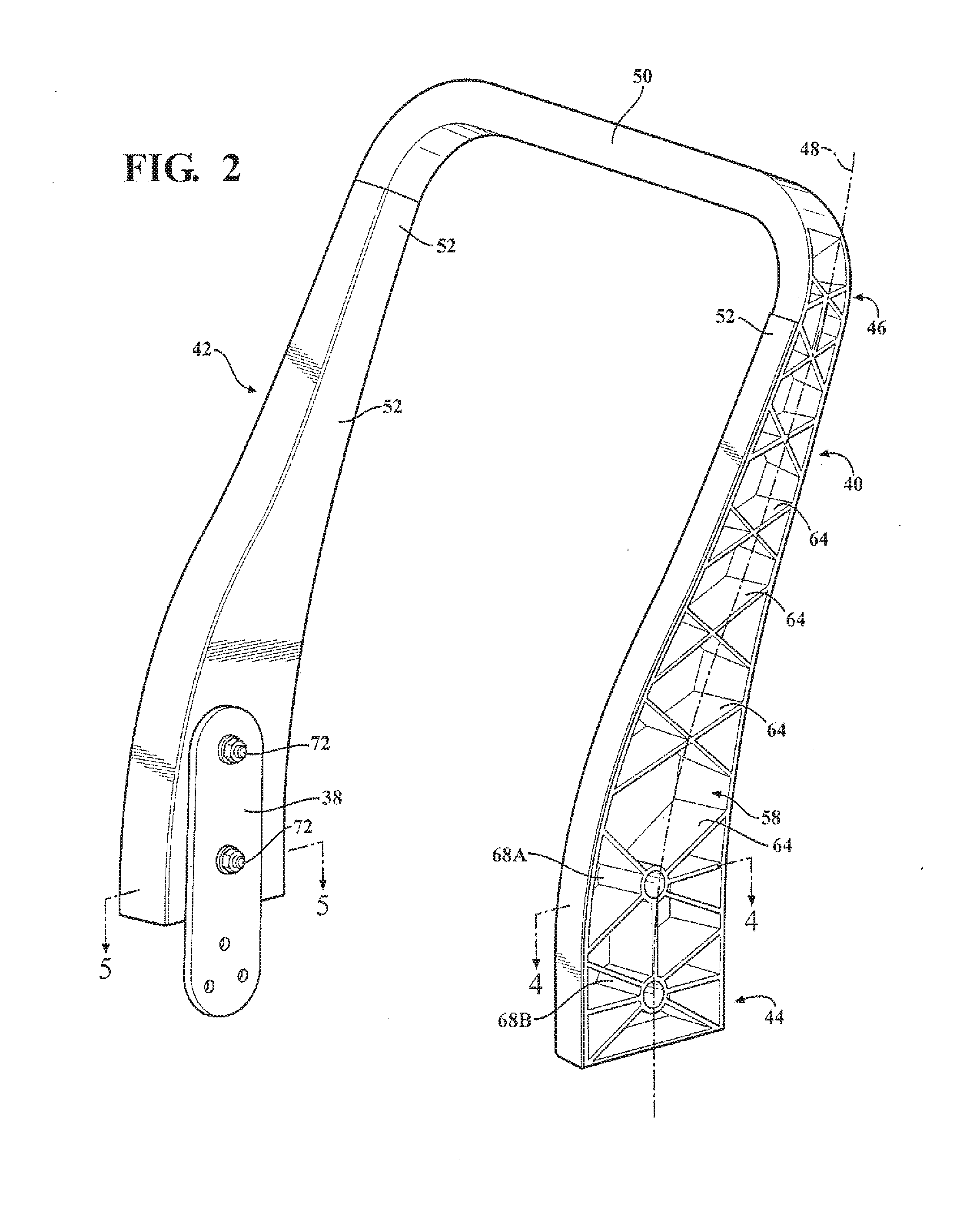

Energy Absorbing Bracket For A Seat Of A Vehicle

ActiveUS20130175833A1Little strengthControlled plastic deformationPedestrian/occupant safety arrangementSeat framesEnergy absorptionEngineering

Owner:BASF SE

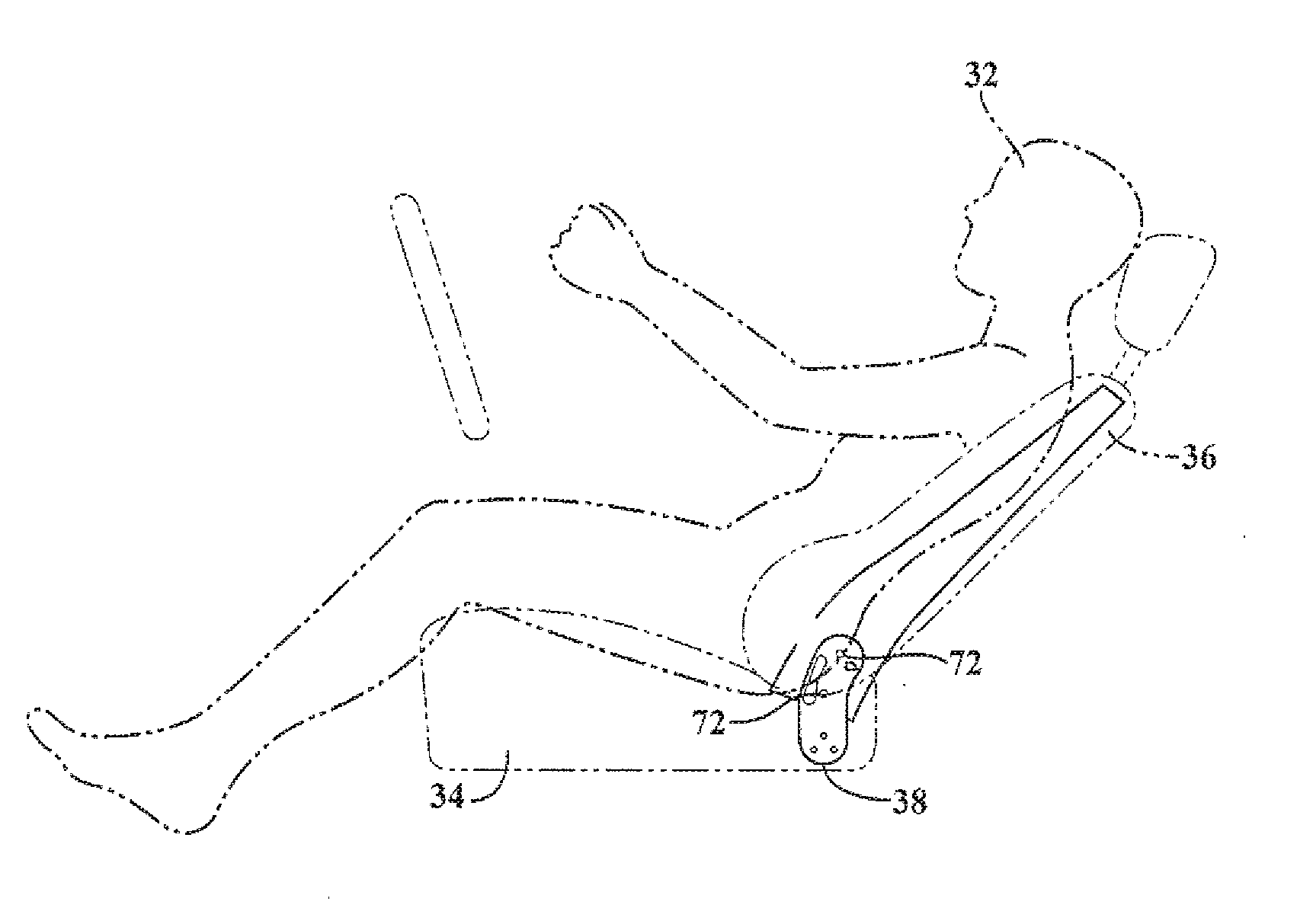

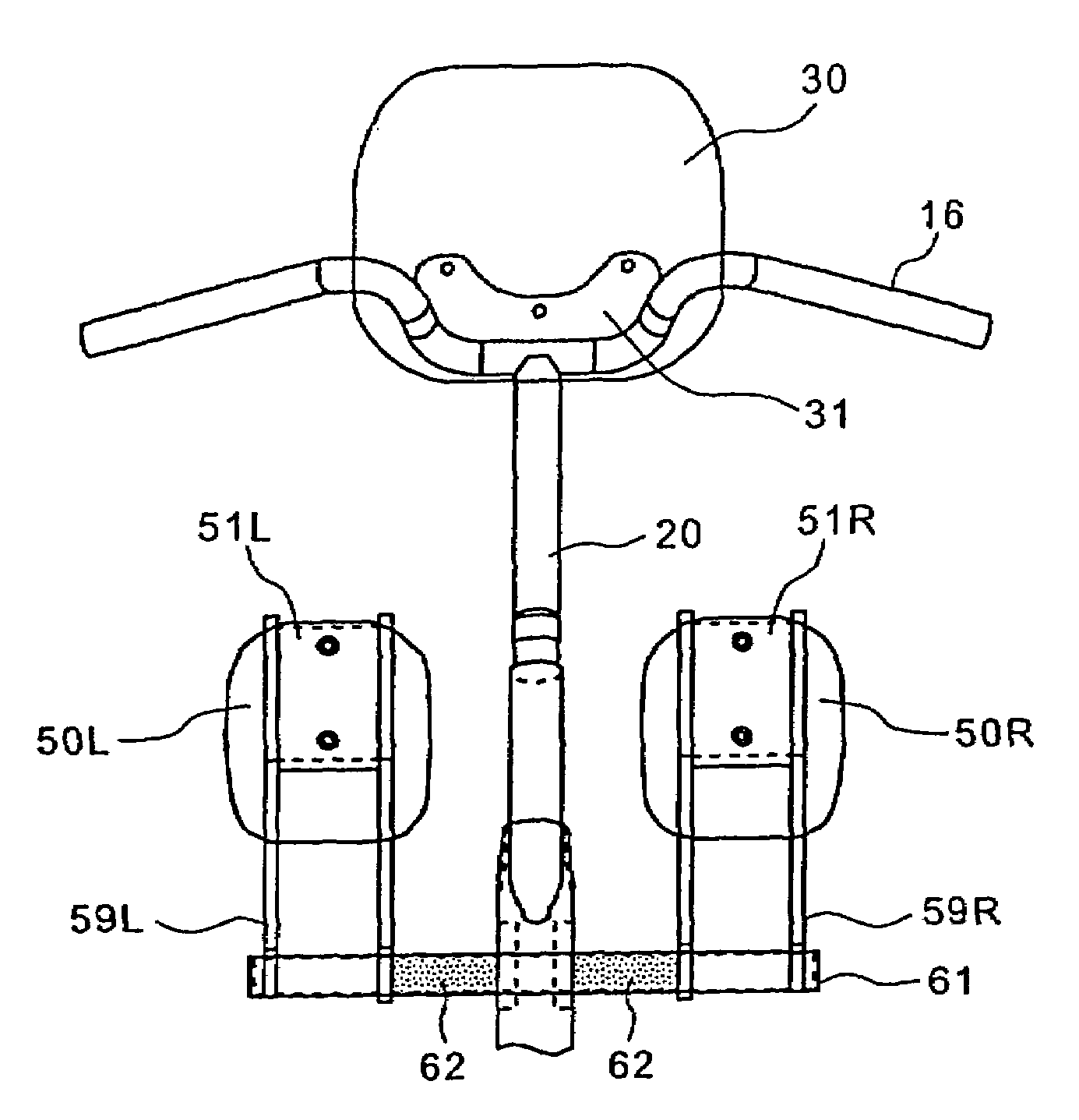

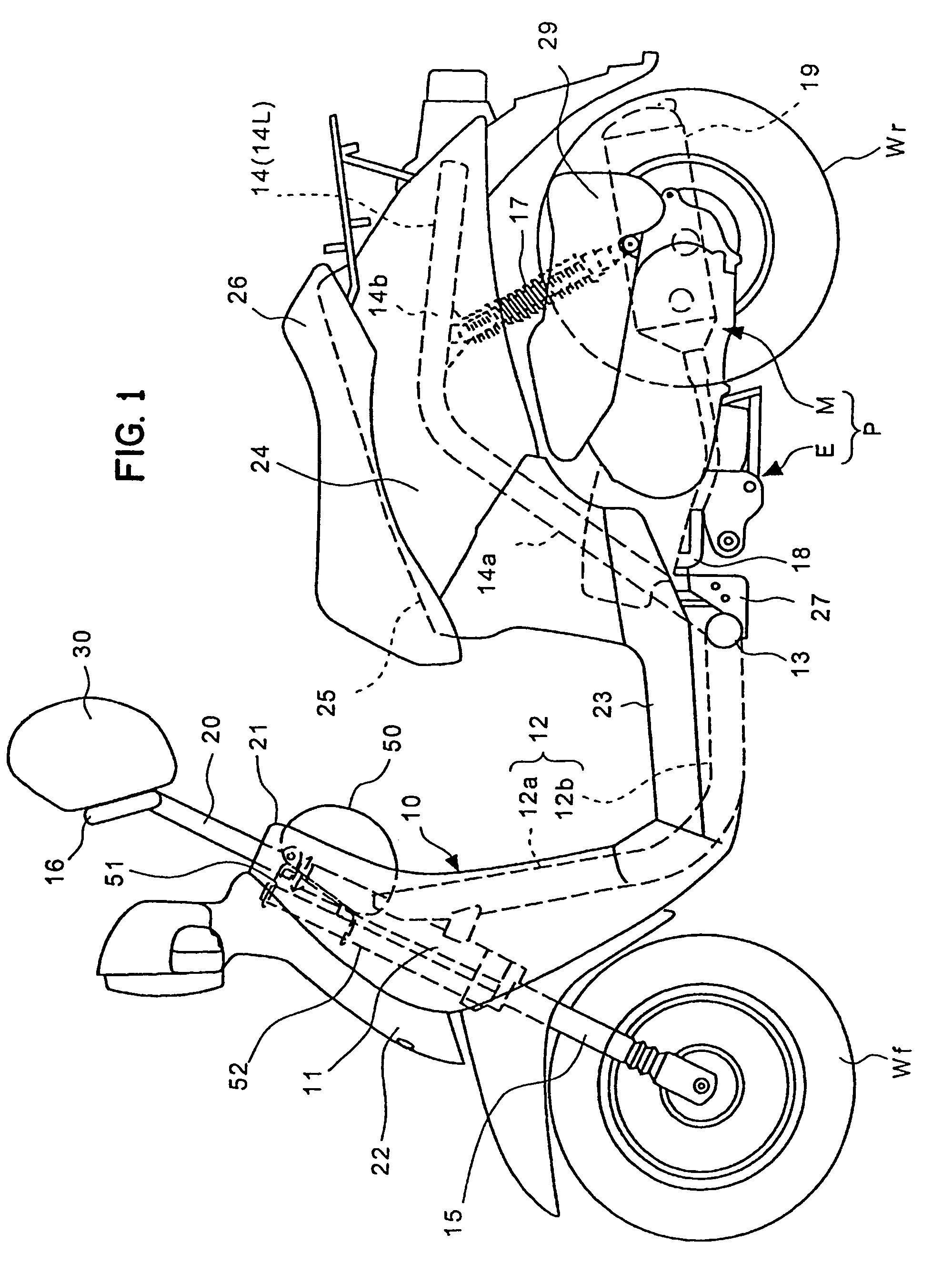

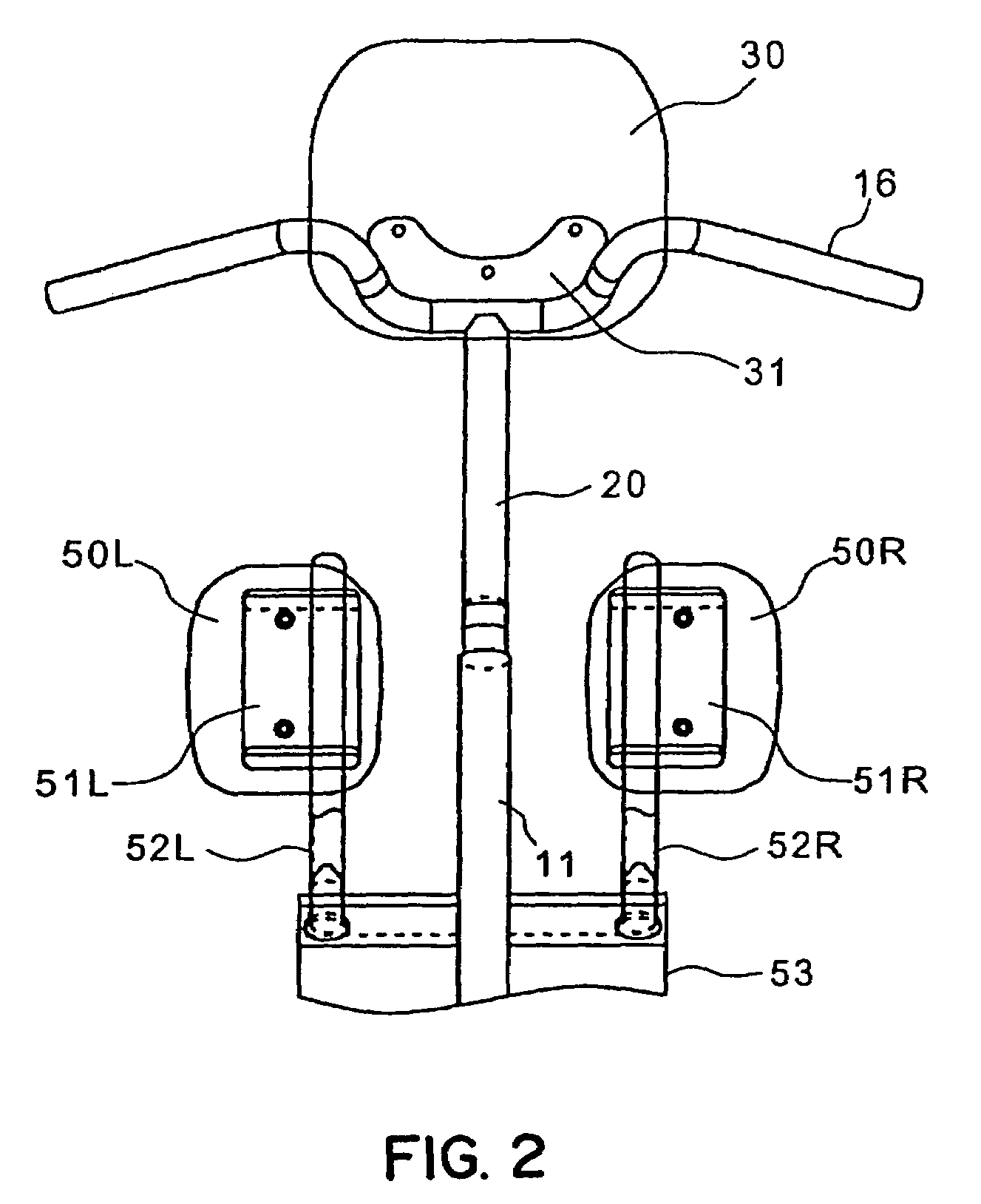

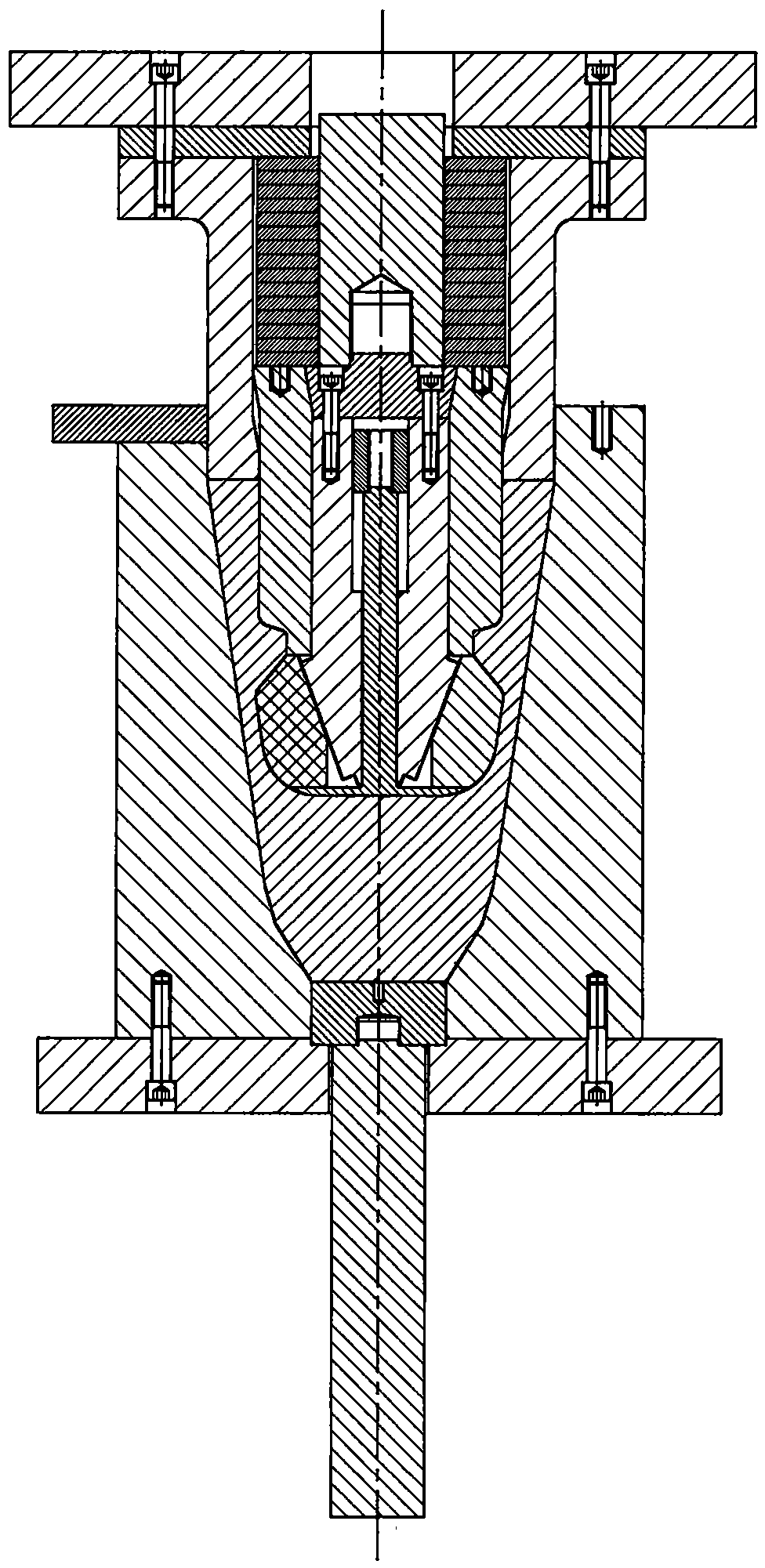

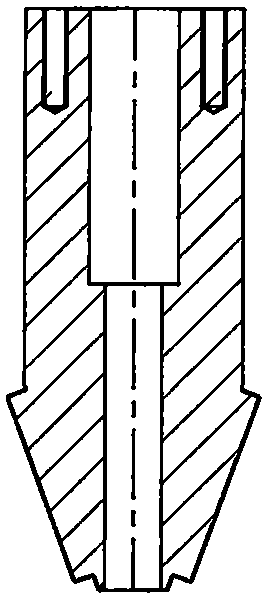

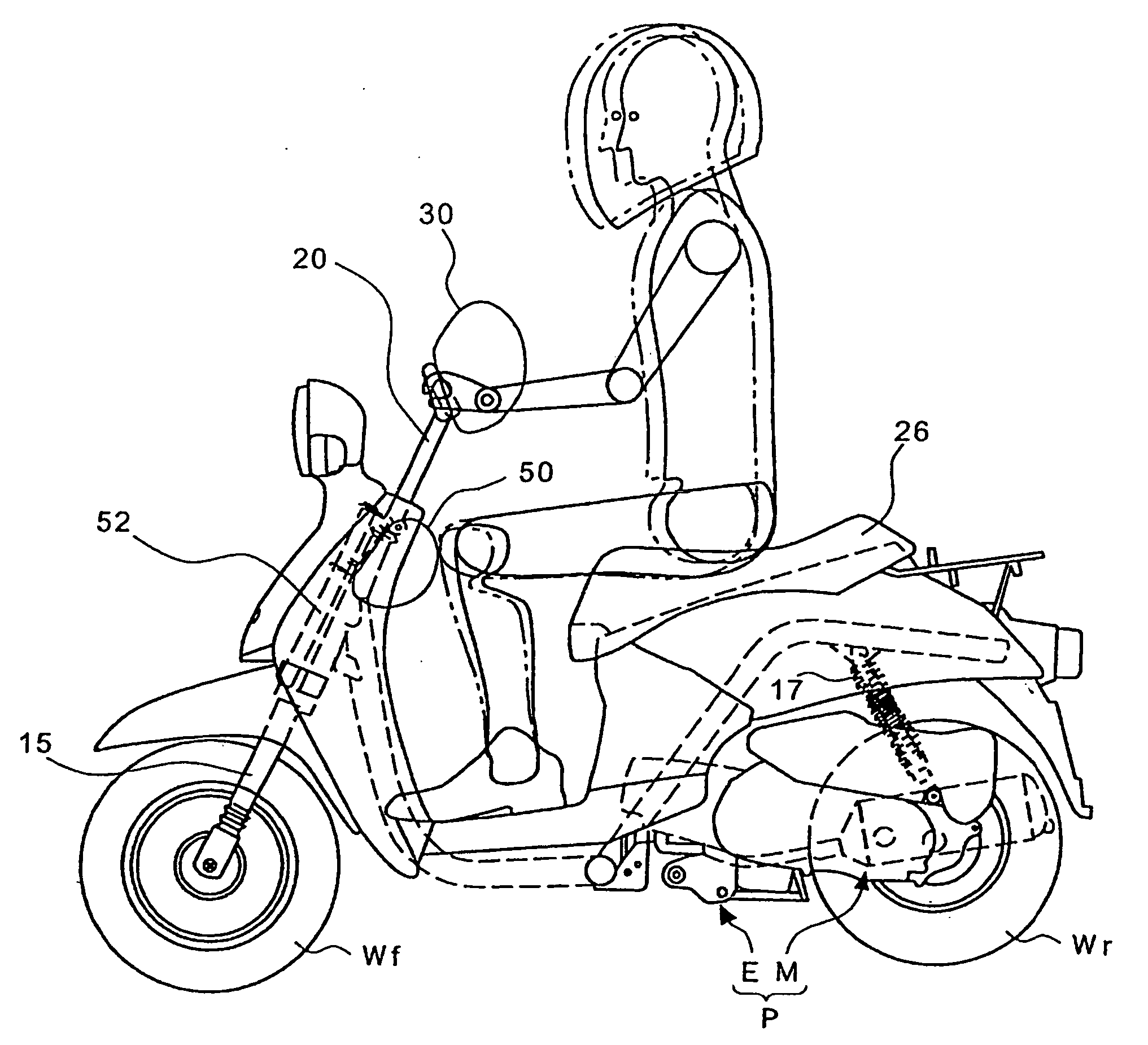

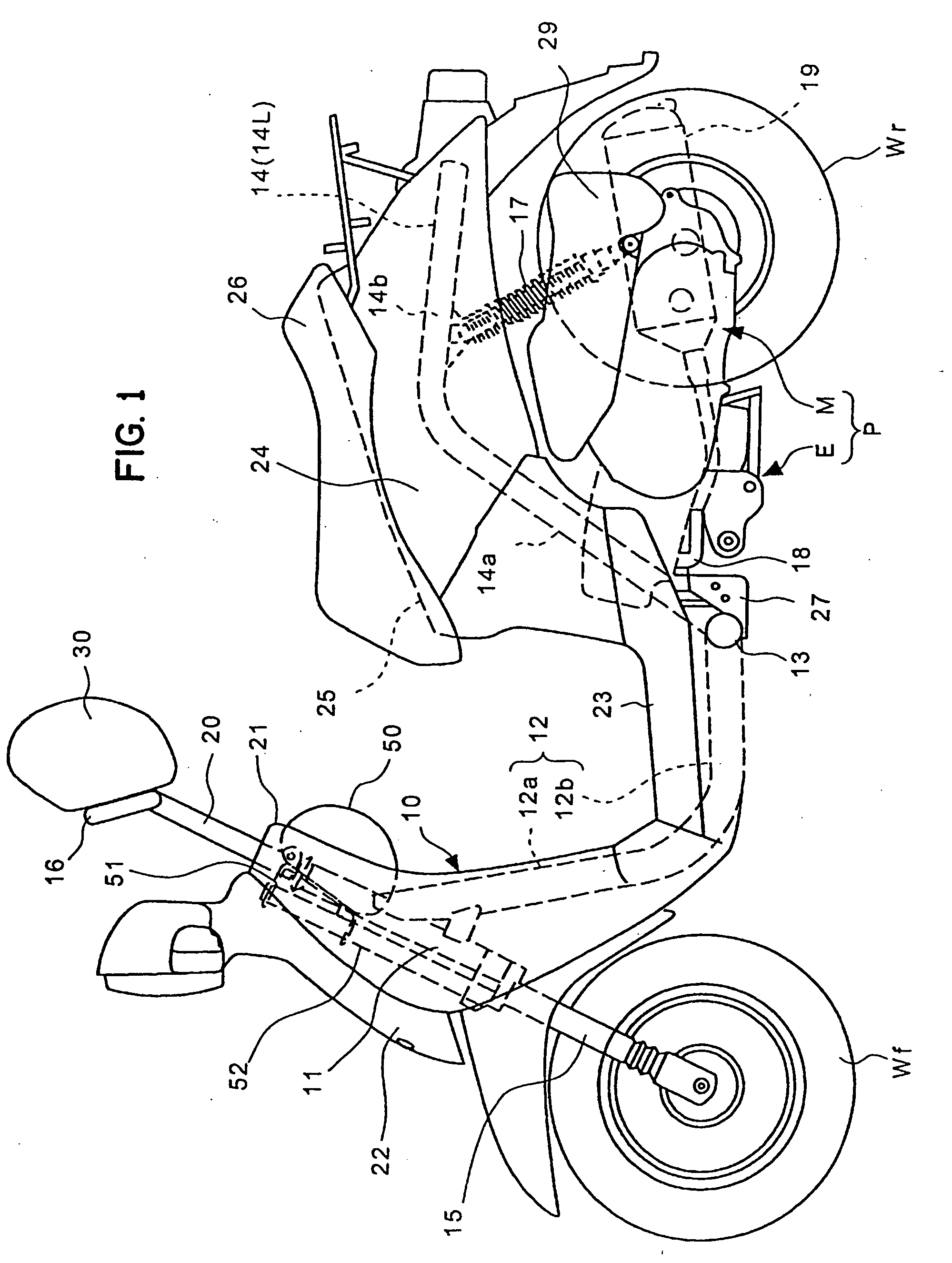

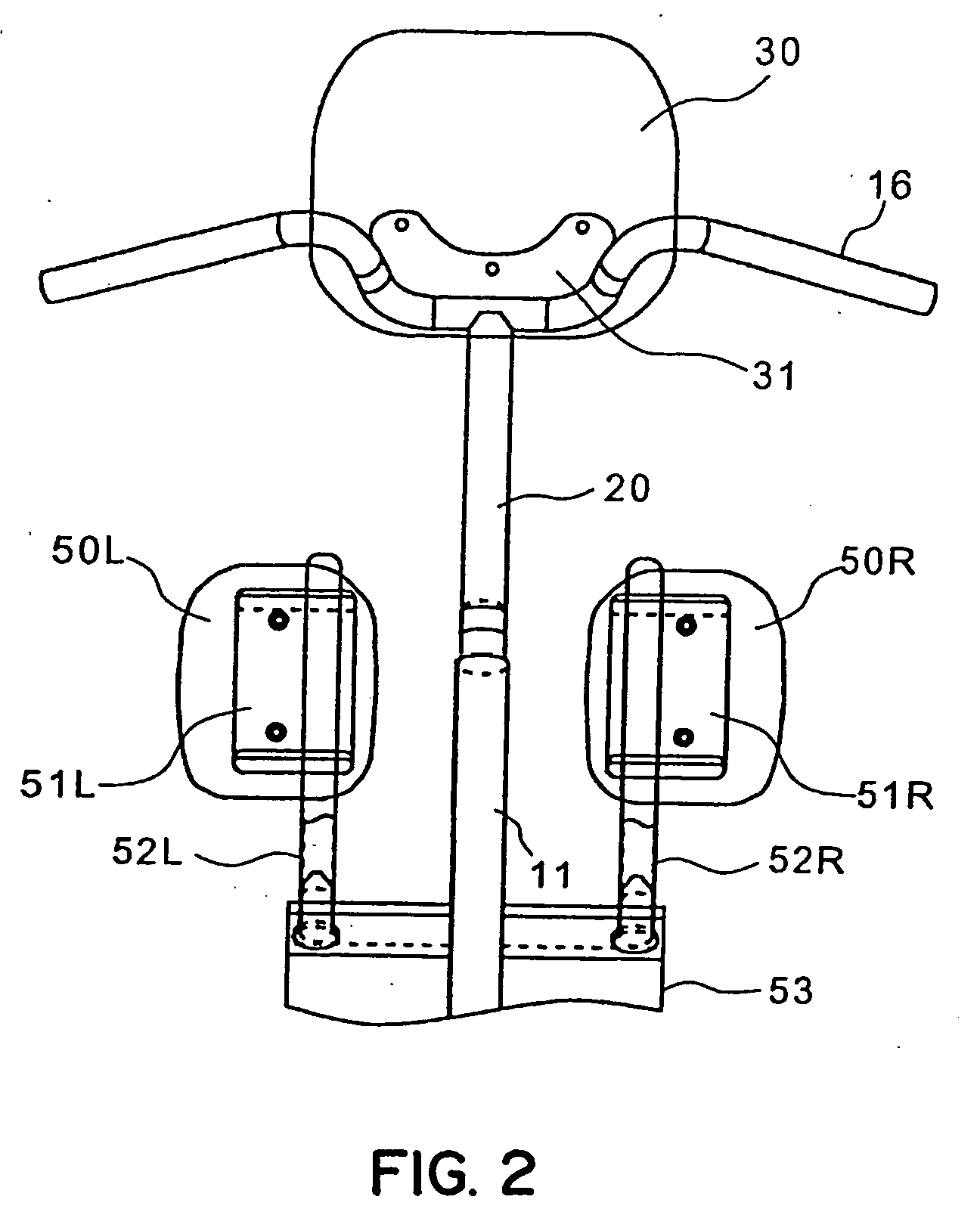

Rider restriction device of two-wheeled vehicle

InactiveUS7364195B2Controlled plastic deformationEasy to limitPedestrian/occupant safety arrangementCycle safety equipmentsEngineeringMechanical engineering

Owner:HONDA MOTOR CO LTD

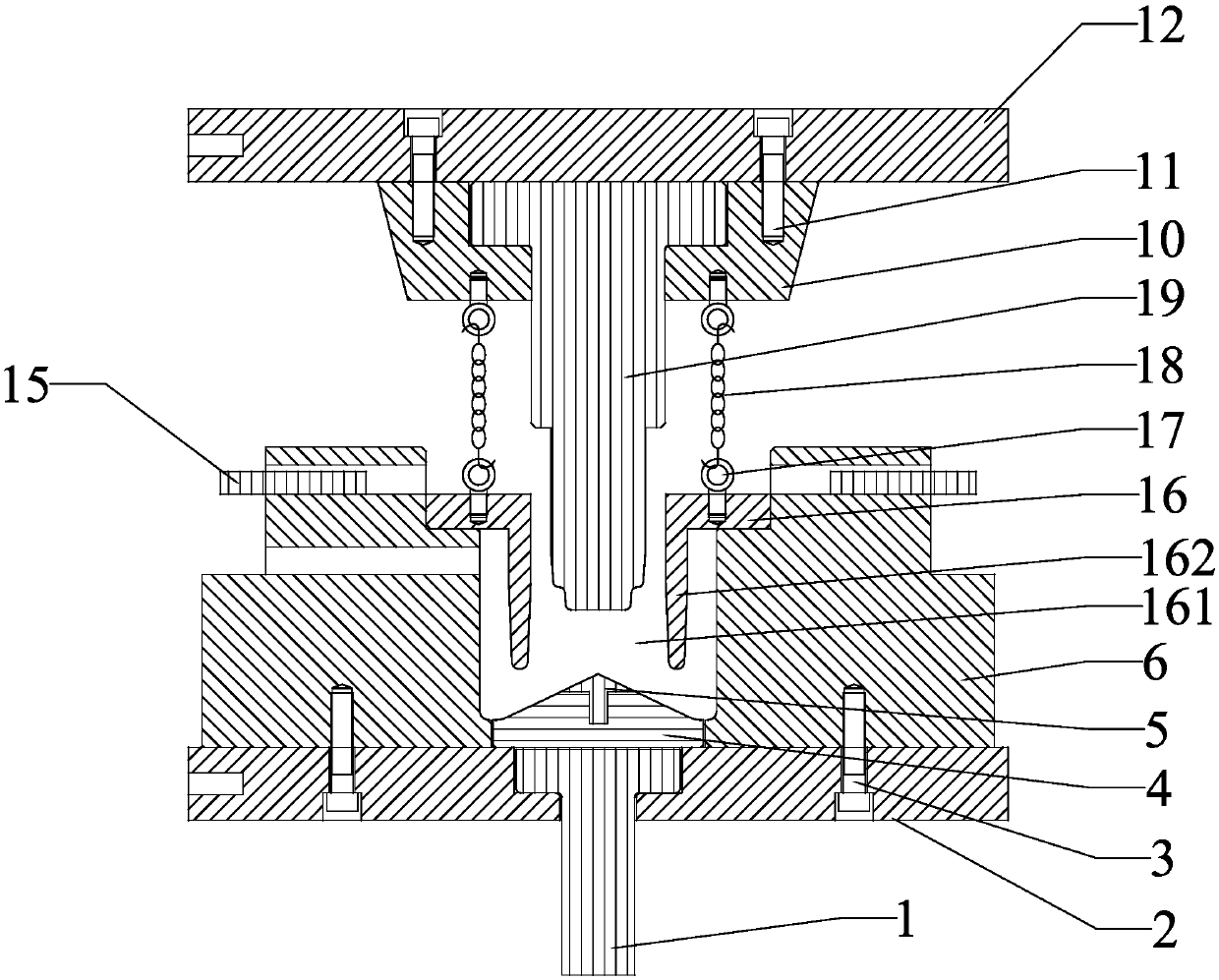

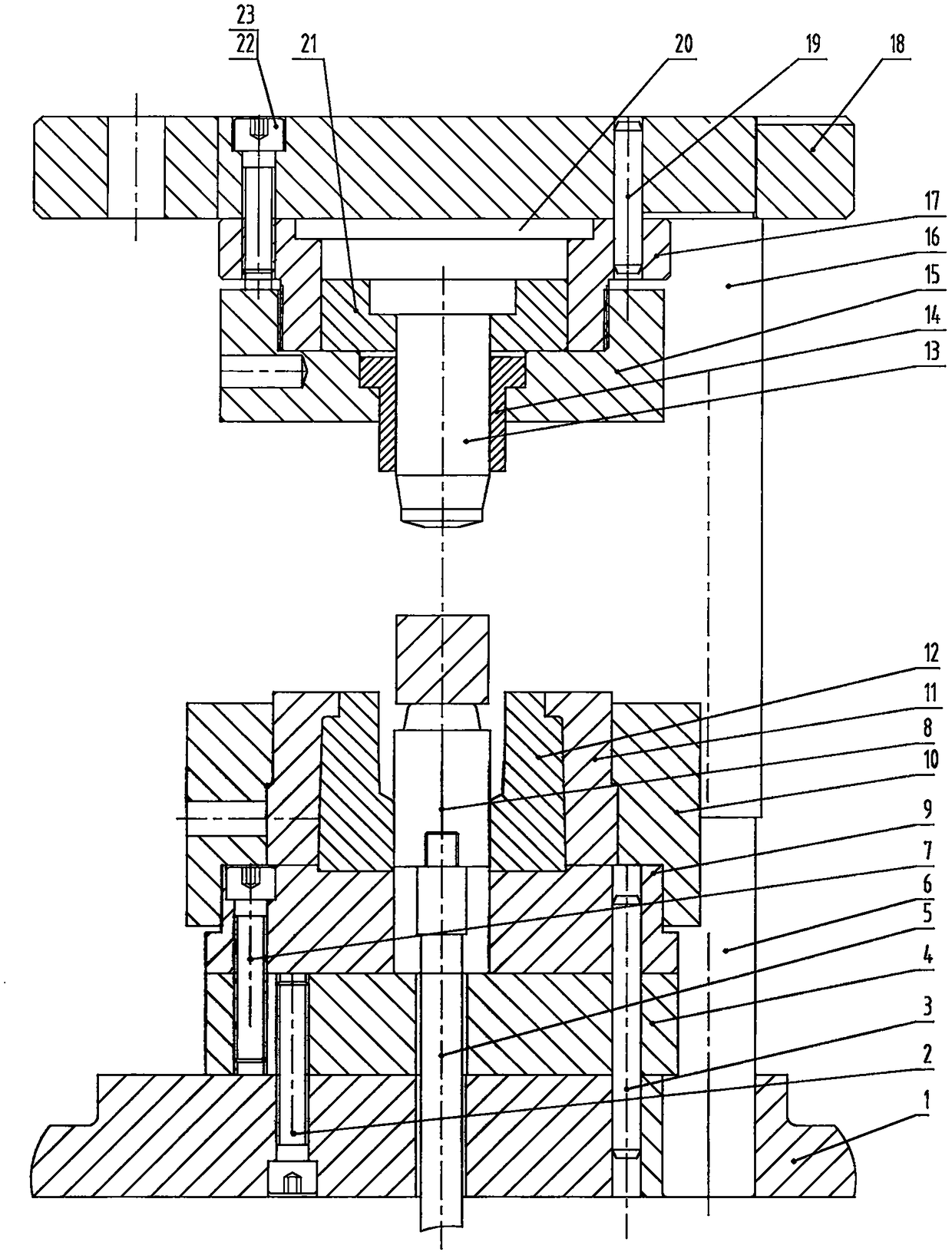

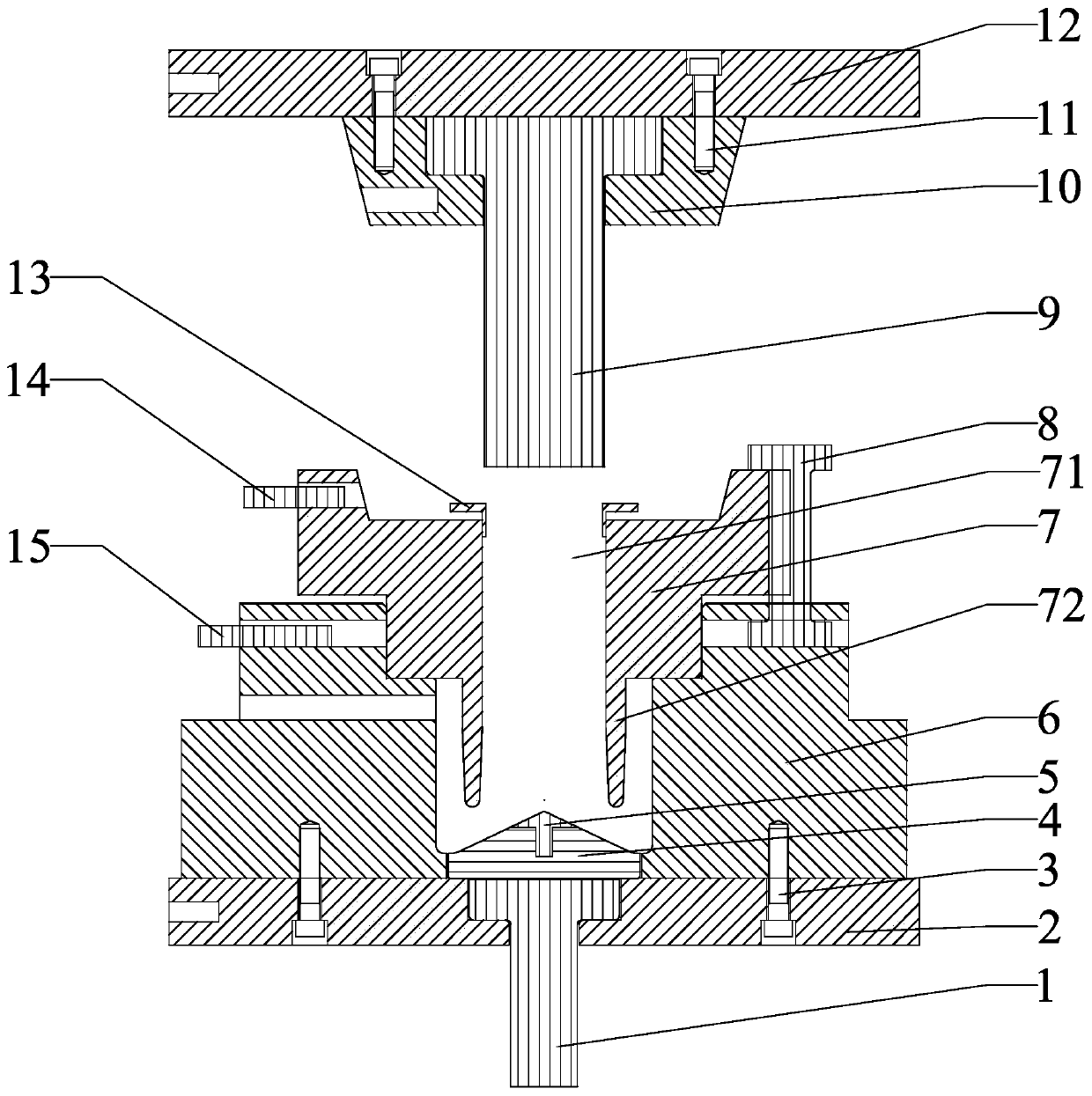

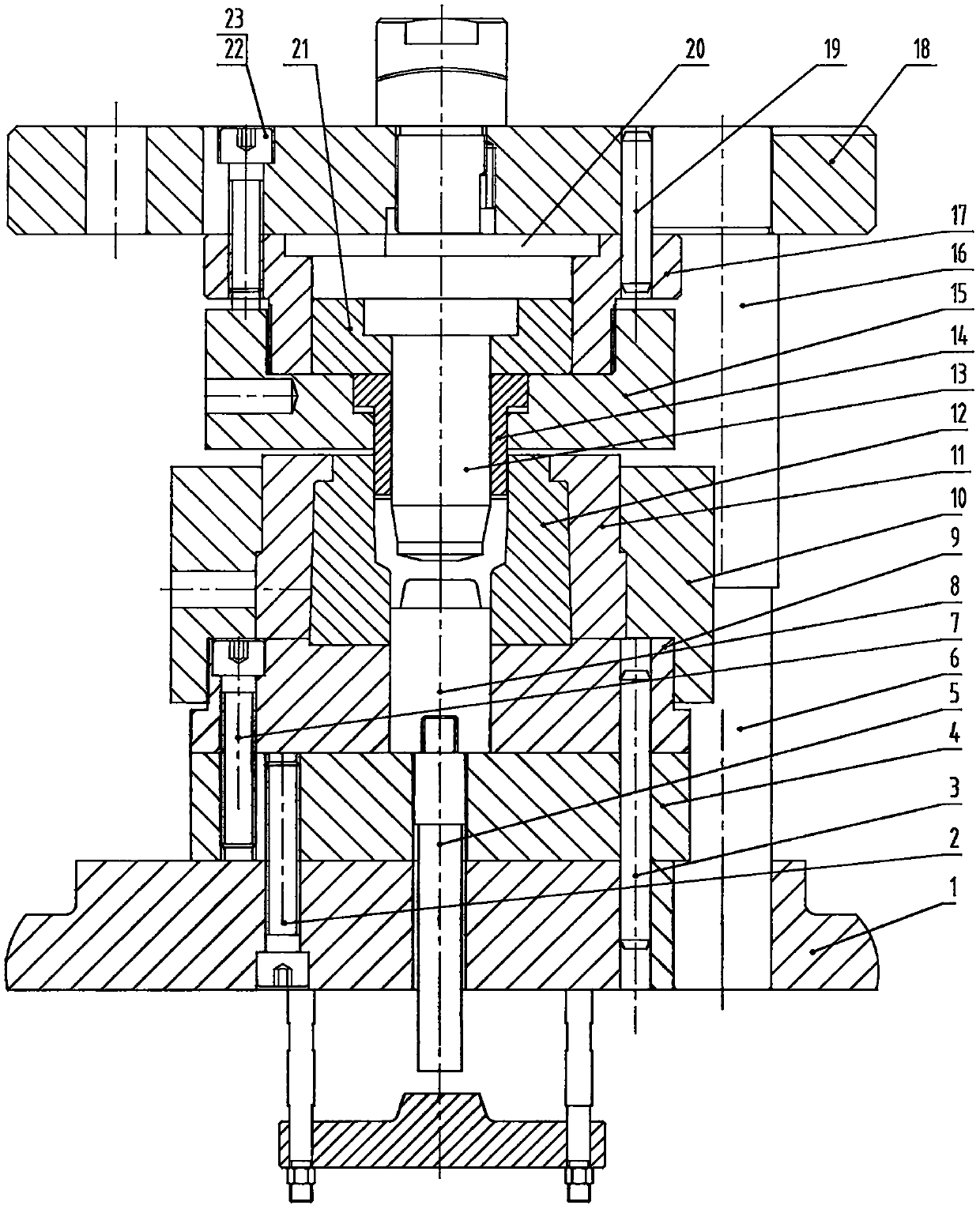

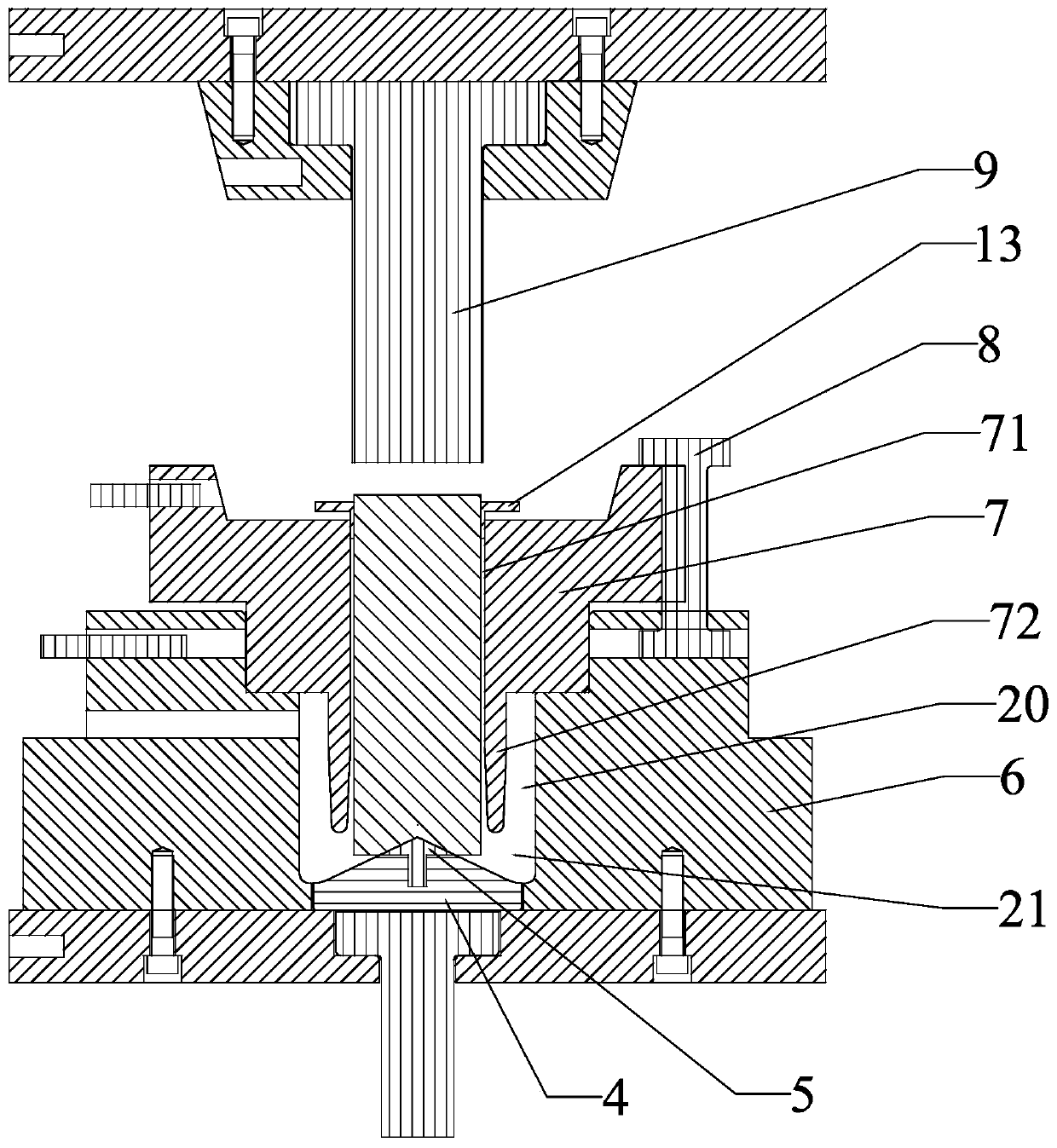

Integral extrusion forming mold for light alloy shell complex inner ring rib

ActiveCN109277461AControl stress stateEnsure orderly flowShaping toolsEjection devicesAlloyMaterials science

The invention discloses an integral extrusion forming mold for a light alloy shell complex inner ring rib. The integral extrusion forming mold comprises an upper mold assembly, an inner support structure assembly and a lower mold assembly, the lower mold assembly comprises a concave mold for accommodating a light alloy cylindrical member, the upper mold assembly comprises a convex mold for downward extrusion of the light alloy cylindrical member, and the inner support structure assembly comprises an upper inner support and a lower flexible filling body inner support; and flexible materials areadopted for making a sand model needed by the inner ring rib through the lower flexible filling body inner support according to the shape of the lower portion of the inner ring rib, the lower flexible filling body inner support is placed in the lower part of the inner ring rib, the shape of the upper portion of the inner ring rib is formed through the upper inner support, and the upper inner support is placed on the upper part of the inner ring rib. By means of the integral extrusion forming mold, the material utilization rate is greatly improved, difficulties caused by precise plastic forming of a sectioning inner support structural material are overcome, the problem of the jamming during mold release is solved, and simultaneous forming of the inner ring rib during overall plastic forming of a large complex light alloy shell member is achieved.

Owner:ZHONGBEI UNIV

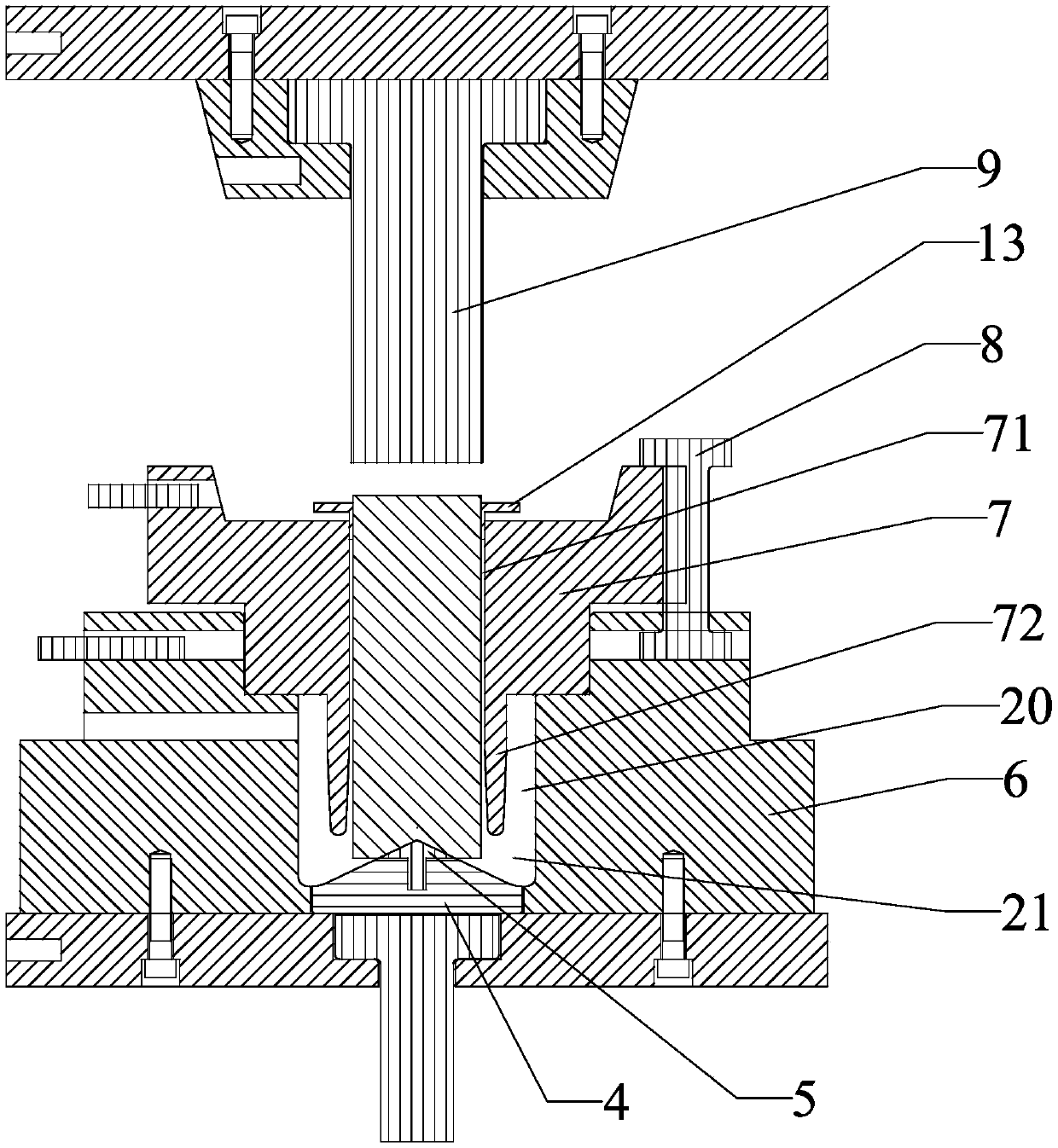

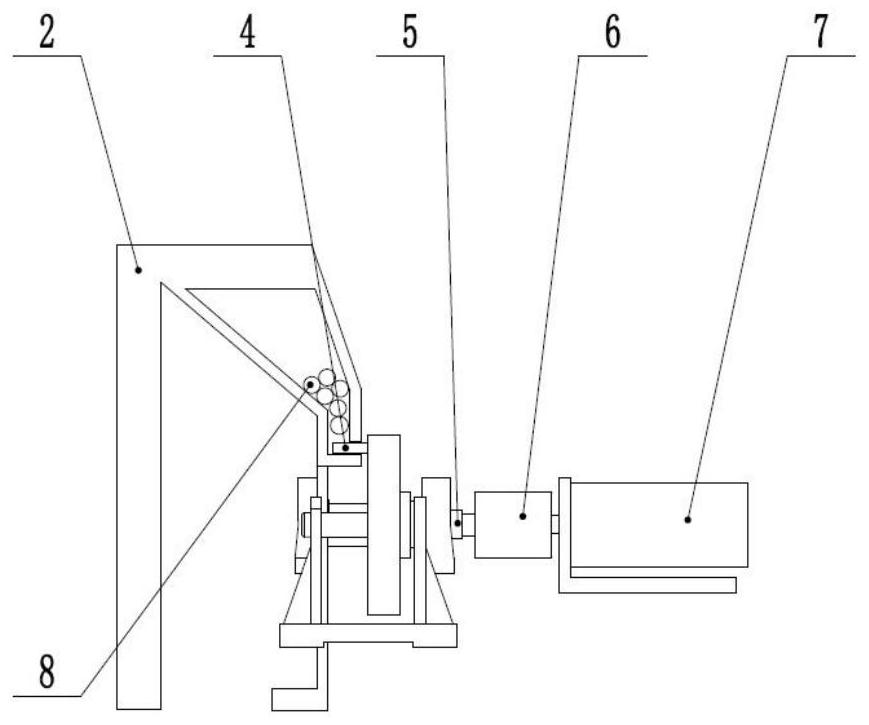

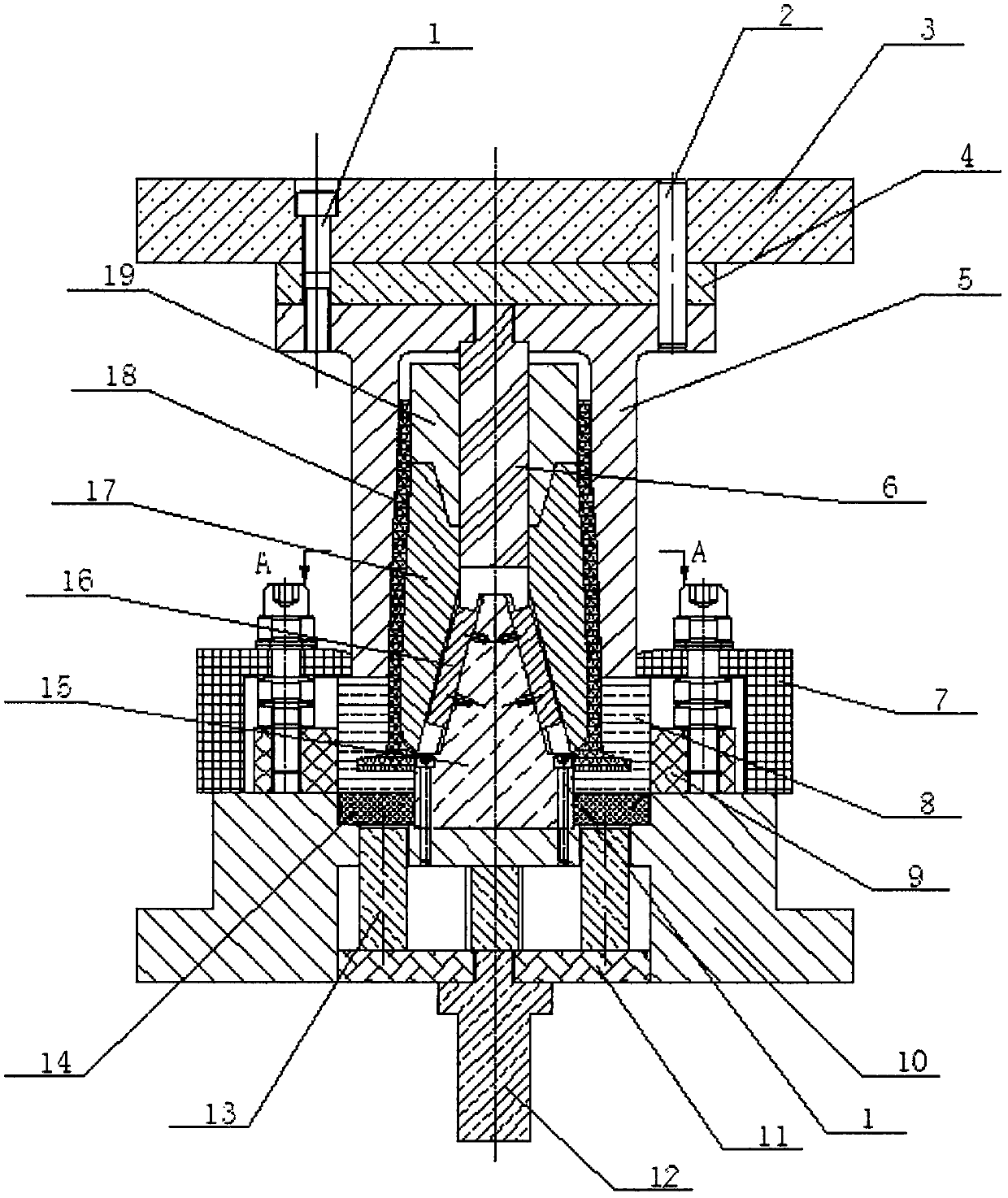

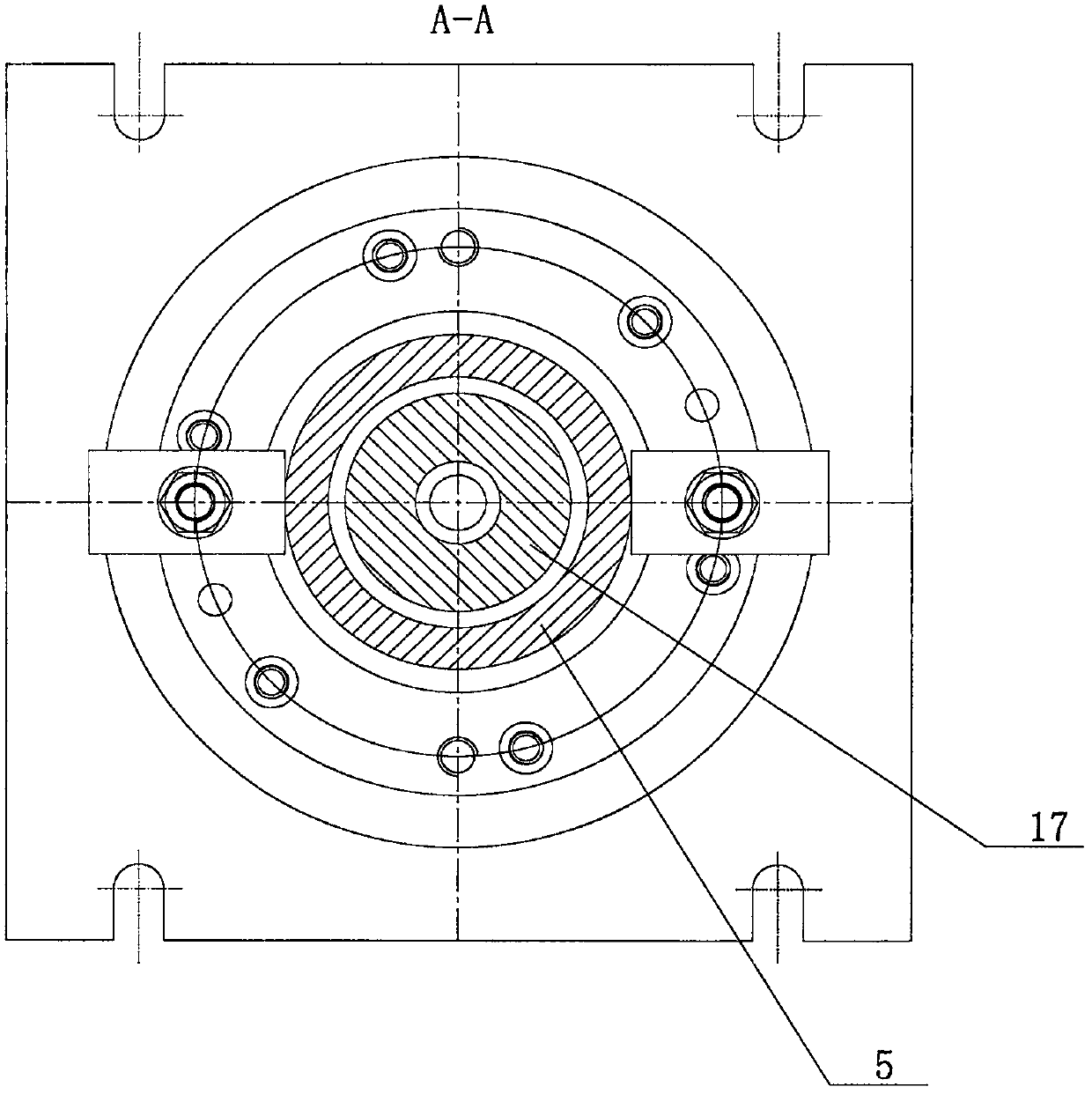

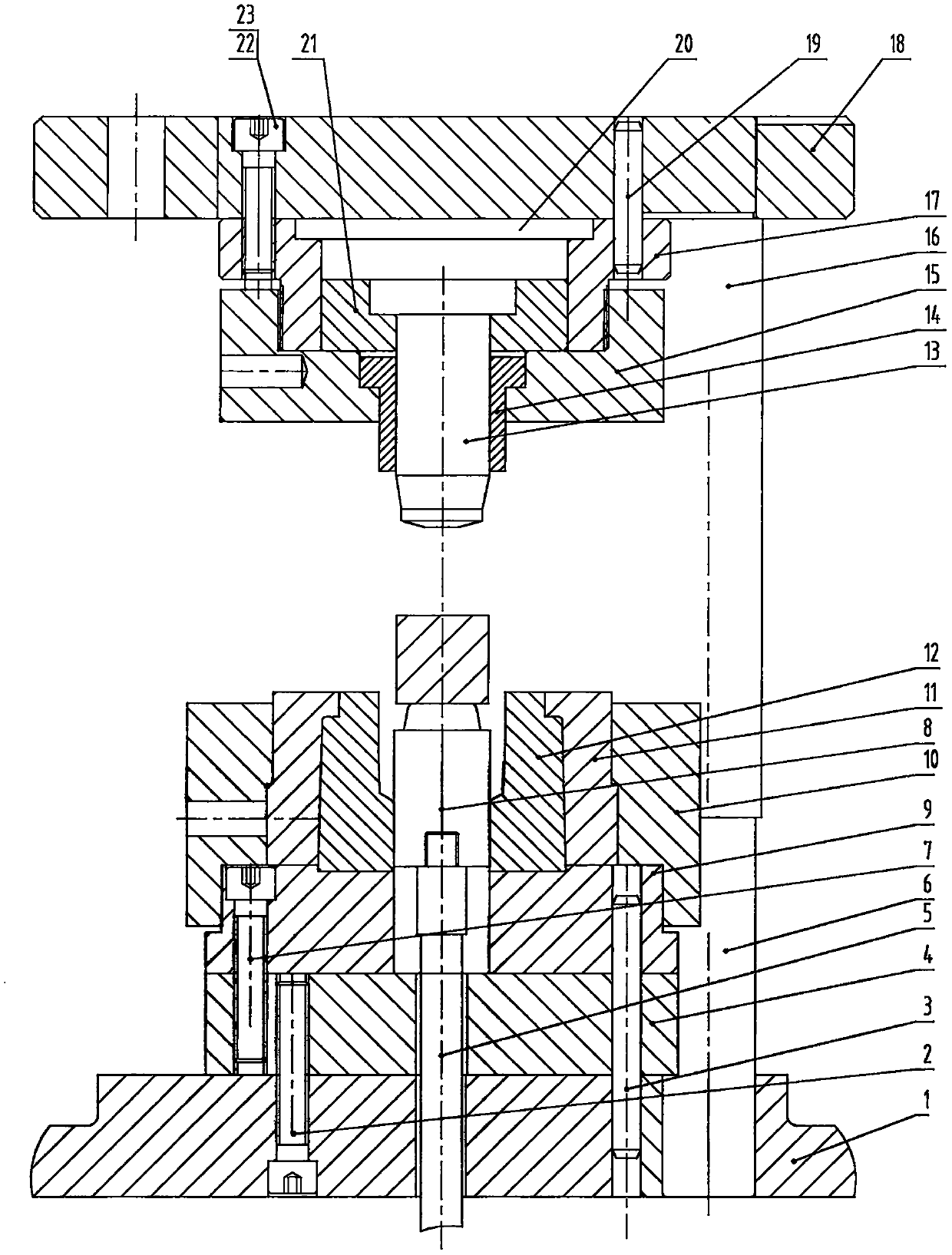

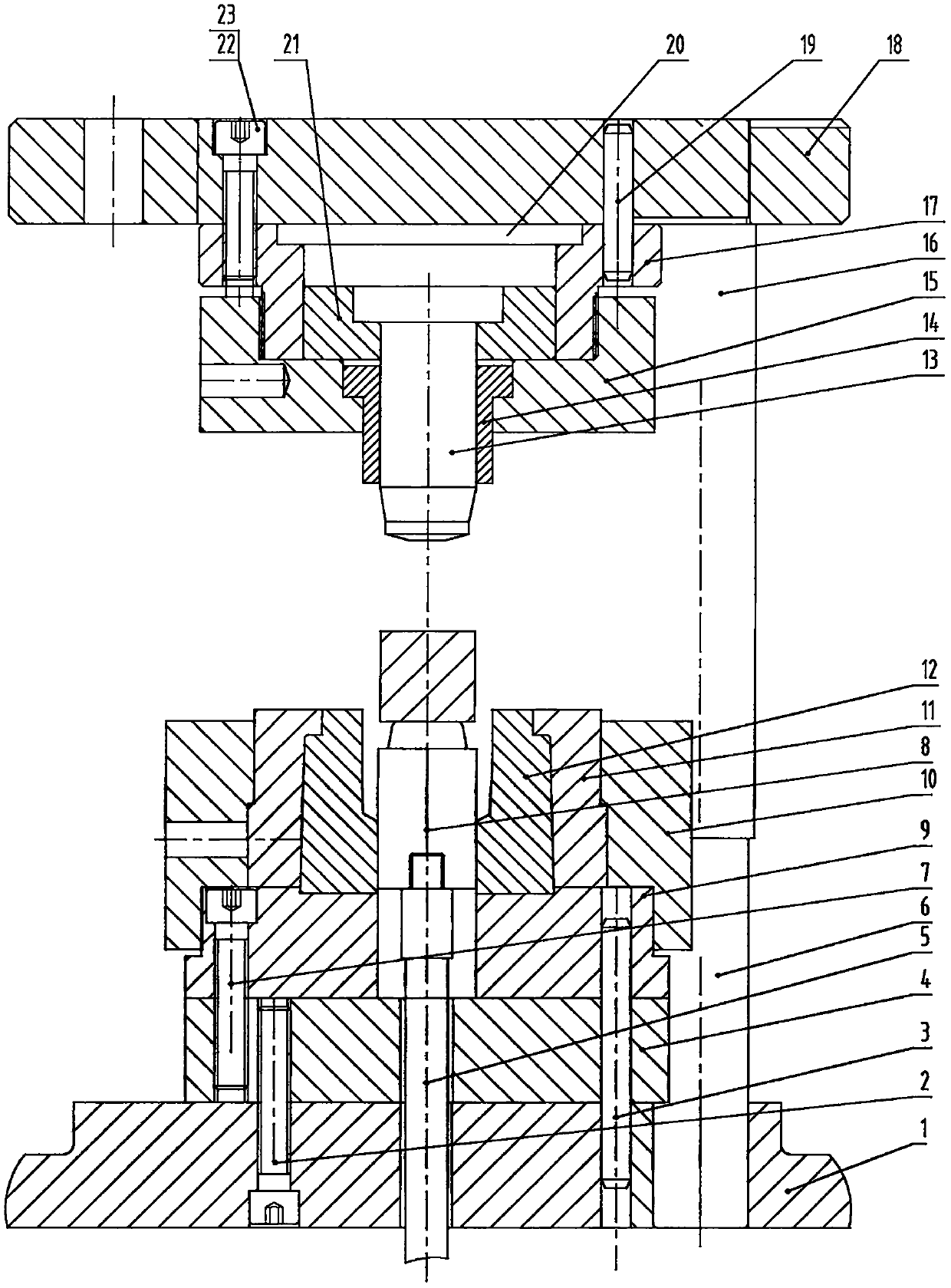

Extrusion moulding mold for branch type light alloy component with big middle and small ends

ActiveCN107639127AProcess stabilityControl stress stateExtrusion diesExtrusion mandrelsAlloyMechanical property

The invention discloses an extrusion moulding mold for branch type light alloy component with the big middle and small ends. The mold comprises an upper mold assembly, a lower mold assembly, an ejector device, a material crushing device and a valving type internal-external support component, wherein the upper mold assembly is arranged above the lower mold assembly, the valving type internal-external support component is arranged between the upper mold assembly and the lower mold assembly, the ejector device is arranged below the lower mold assembly and is in clearance fit connection with the lower mold assembly, the top end of the ejector device is in contact fit connection with the valving type internal-external support component, and the material crushing device is fixedly arranged abovethe lower mold assembly and is arranged outside the upper mold assembly and the valving type internal-external support component. The invention adopts a hot-extrusion shrink-opening method to realizeprecise plastic moulding of the complicated branch type light alloy components with the big middles and small ends, so that problems in a conventional production method can effectively be overcome, the formability of light alloys is improved, the comprehensive mechanical properties of the formed component is improved, the material utilization rate is greatly increased, the energy is saved and theconsumption is reduced.

Owner:ZHONGBEI UNIV

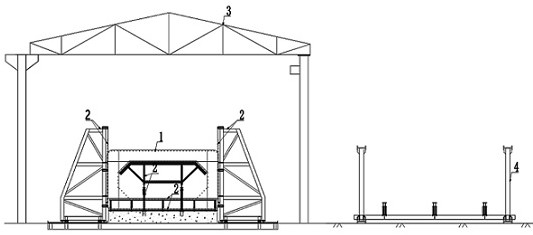

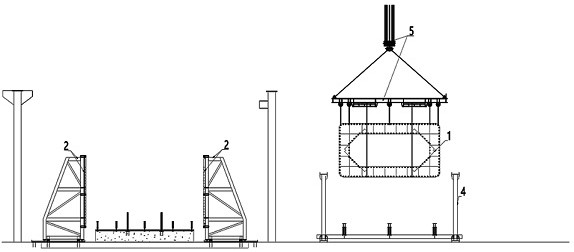

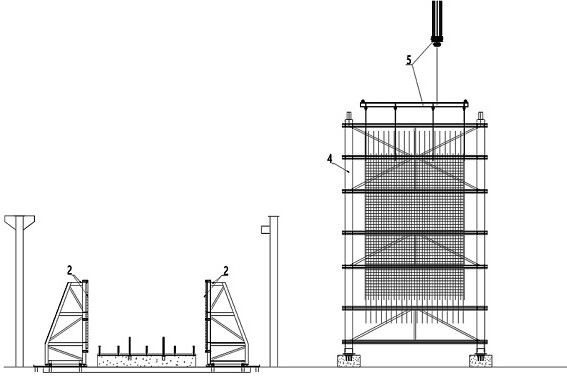

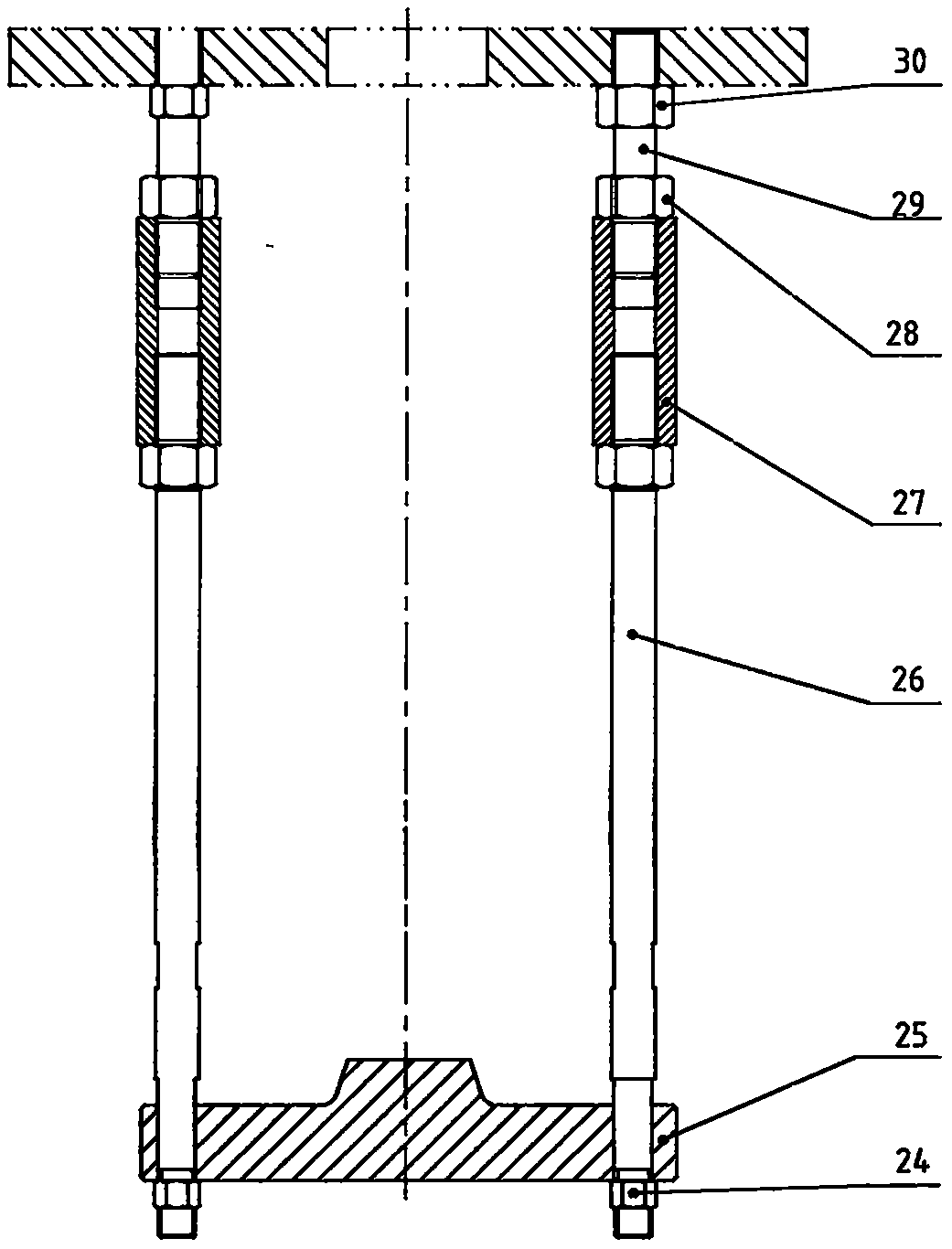

Rapid binding device for steel reinforcement framework of high and large pier body and construction method of rapid binding device

InactiveCN111979917AAchieve dimensional control accuracyEnsure the size of the structureBridge structural detailsBridge erection/assemblyRebarControl theory

The invention relates to a rapid binding device for a steel reinforcement framework of a high and large pier body. The rapid binding device comprises a steel reinforcement binding jig frame, a steering structure and a hoisting system. A construction method of the rapid binding device comprises the steps that (1) the steel reinforcement framework is horizontally bound on the horizontal binding jigframe; (2) the horizontally bound steel reinforcement framework is hoisted to the steering structure through the hoisting system, and then the steering structure is hoisted to enable the steel reinforcement framework to be turned to the vertical direction from the horizontal direction; and (3) the steel reinforcement framework continues to be hoisted and vertically hoisted to a pier position to beinstalled. The rapid binding device has the advantages that vertical binding is changed into horizontal operation, high-altitude operation is changed into low-altitude operation, the safety risk is controlled within a reasonable range, and the first safety and people-oriented effect are truly achieved; the construction quality is ensured, the risk can be reduced, and operation is safe, convenientand fast; and meanwhile, the work efficiency is greatly improved, the construction time for binding the steel reinforcement framework of the high and large pier body can be well shortened, and high popularization value is achieved.

Owner:THE 2ND ENG CO LTD MBEC

Integral extrusion forming method of light alloy shell body complex inner ring rib

The invention discloses an integral extrusion forming method of a light alloy shell body complex inner ring rib. The invention relates to an integral extrusion forming mold of the light alloy shell body complex inner ring rib, the mode comprises a lower flexible filling body inner support, and the lower flexible filling body inner support adopts a soft material to be made into a sand mold according to the shape of the lower part of the inner ring rib; a light alloy cylindrical part and the mold are heated and subjected to heat preservation, then the light alloy cylindrical part is placed intothe mold, an extrusion forming inner ring rib stage is entered, when the stage is finished, a press machine drives the mold to be separated from the inner ring rib, the light alloy cylindrical part isseparated from the mold, and finally, the temperature is controlled to enable the lower flexible filling body inner support to be discretized. According to the method, a material utilization rate isgreatly improved, the problem of difficulty brought by using a valving inner support structure material when precise plastic forming is carried out is overcome, the problem of blockage during mold stripping is solved, so that the effect of protecting the mold is achieved, and the simultaneous forming of the inner ring rib during integral plastic forming of the large-scale complex light alloy shellbody component.

Owner:ZHONGBEI UNIV

Rider restriction device of two-wheeled vehicle

InactiveUS20060048989A1Controlled plastic deformationEasy to limitPedestrian/occupant safety arrangementCycle safety equipmentsEngineering

Owner:HONDA MOTOR CO LTD

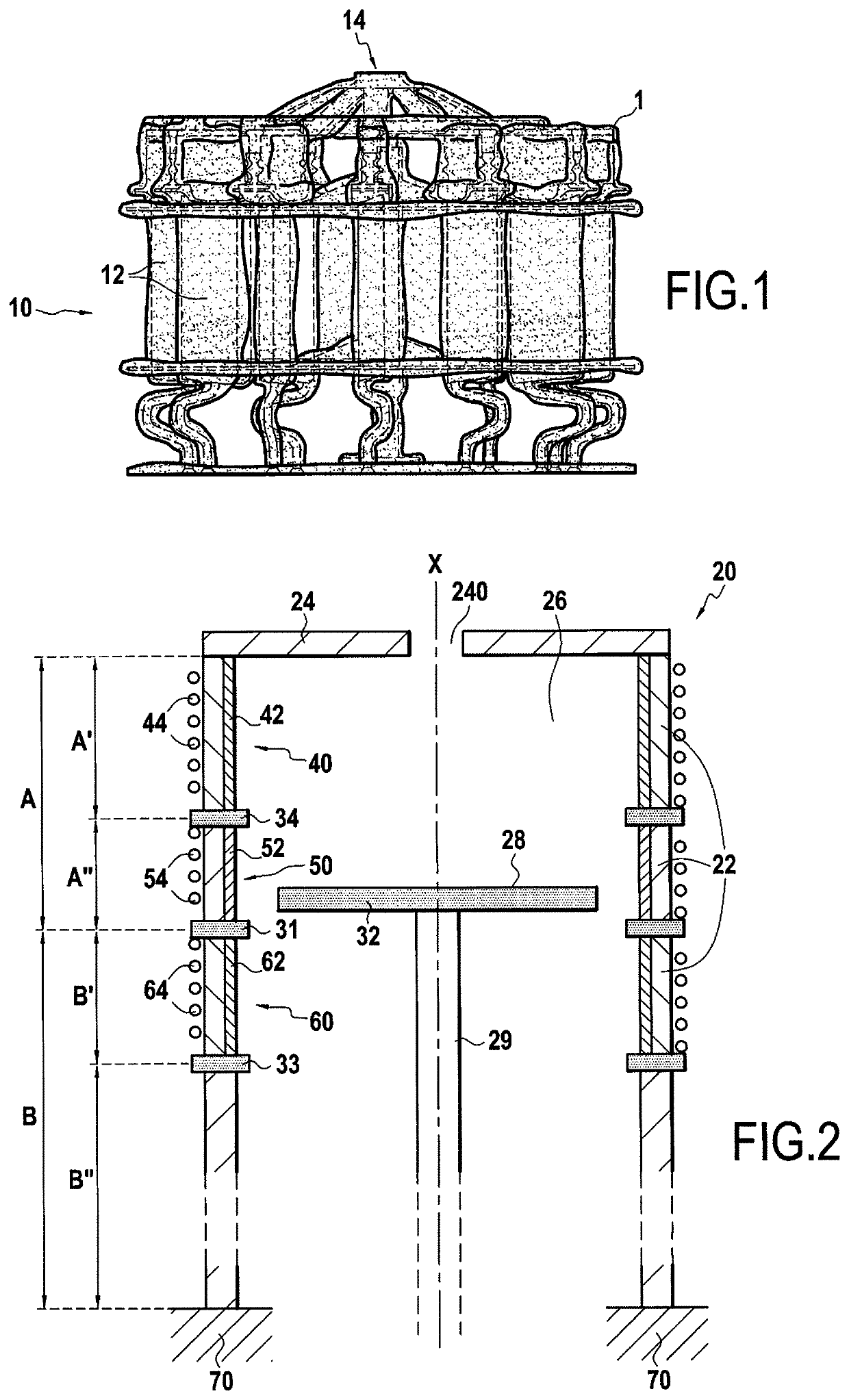

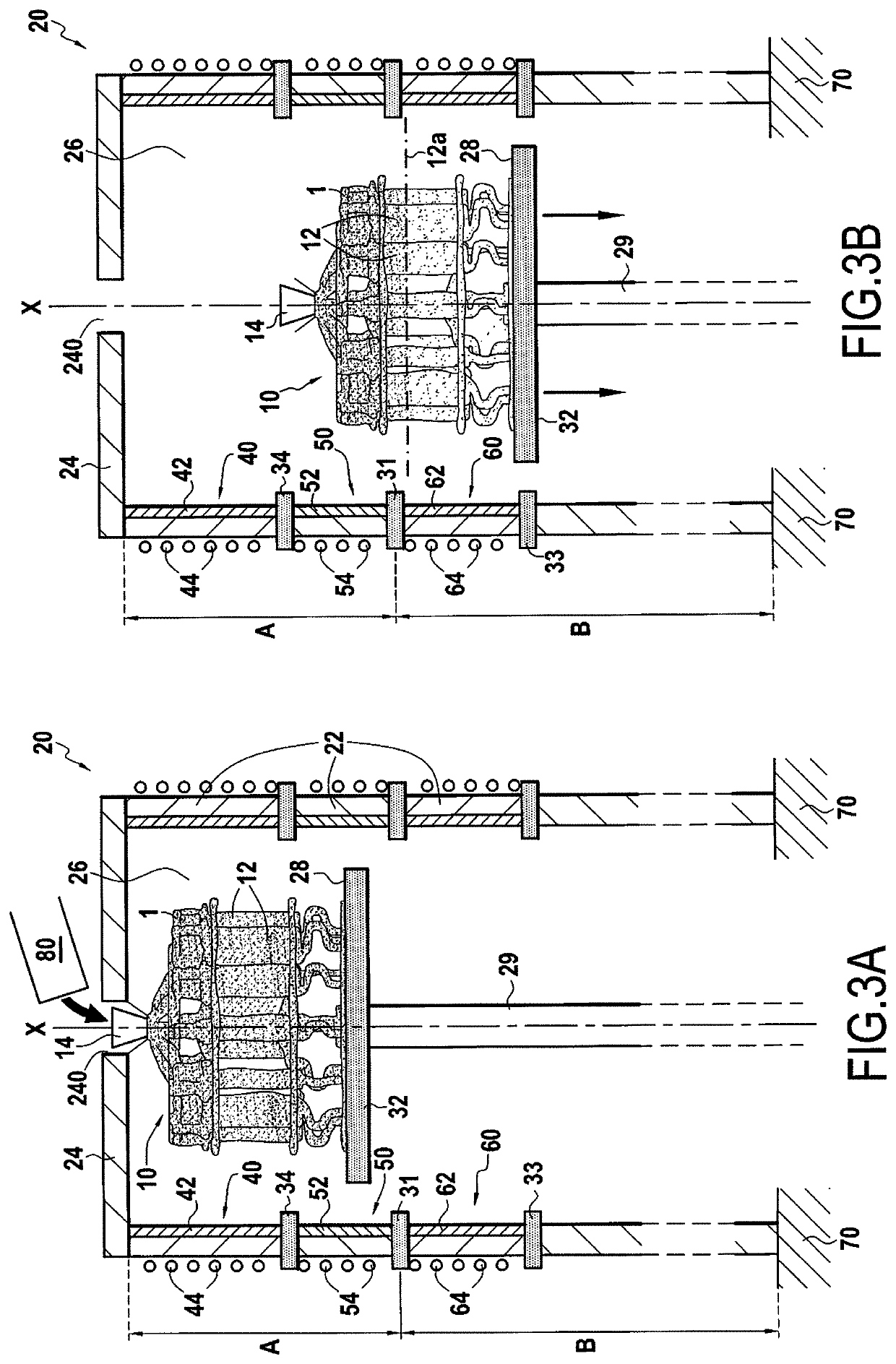

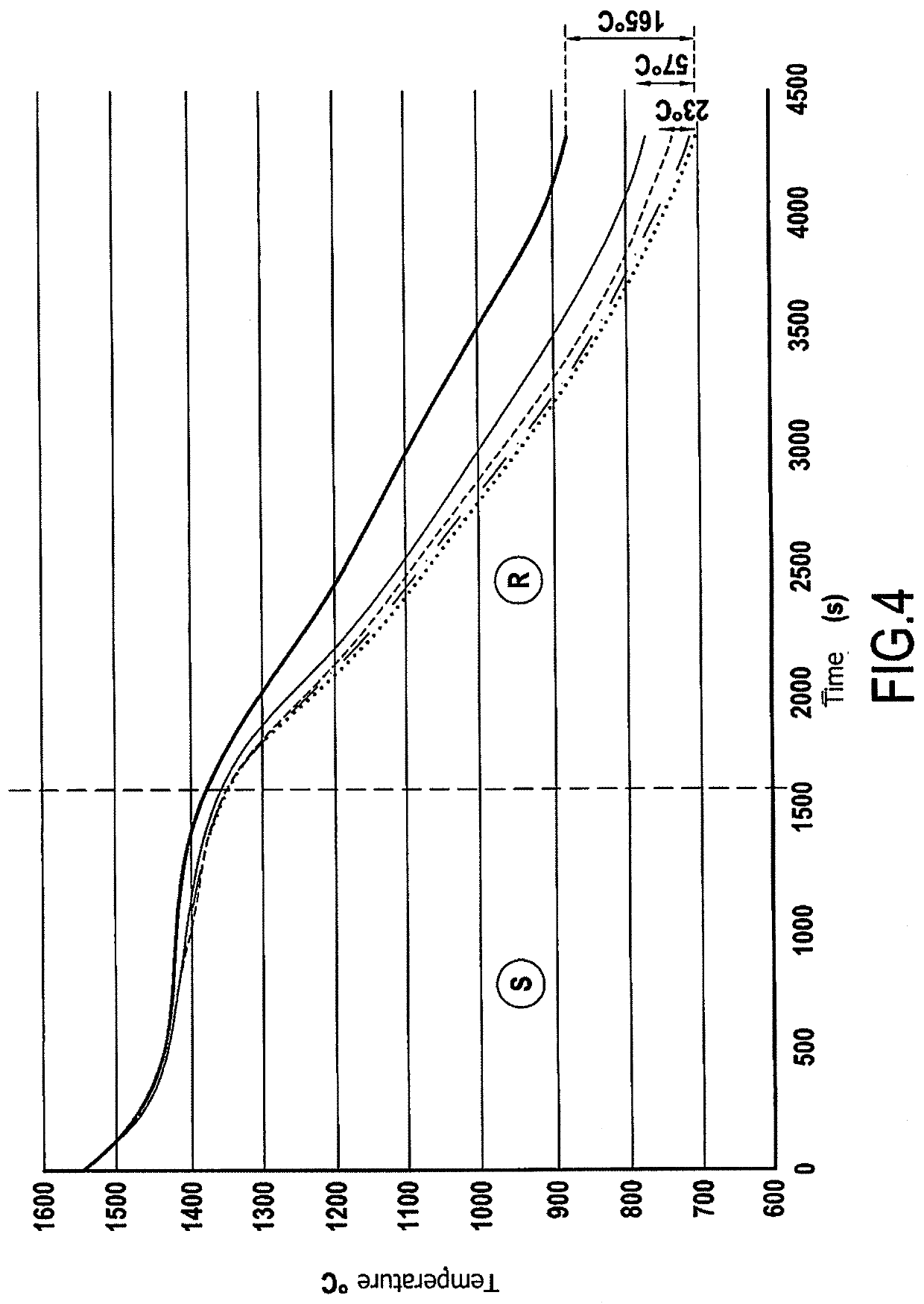

Directional solidification cooling furnace and cooling process using such a furnace

A directional solidification cooling furnace for metal casting part comprises: a cylindrical internal enclosure having a vertical central axis and a mold support arranged in the internal enclosure; the internal enclosure comprising a casting zone and a cooling zone, the casting zone and the cooling zone being superposed one on the other; the casting and cooling zones being thermally insulated from each other when the mold support is arranged in the casting zone by means of a heat shield that is stationary and by means of a second heat shield that is carried by the mold support; the casting zone including at least a first heating device, and the cooling zone including a second heating device.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A +1

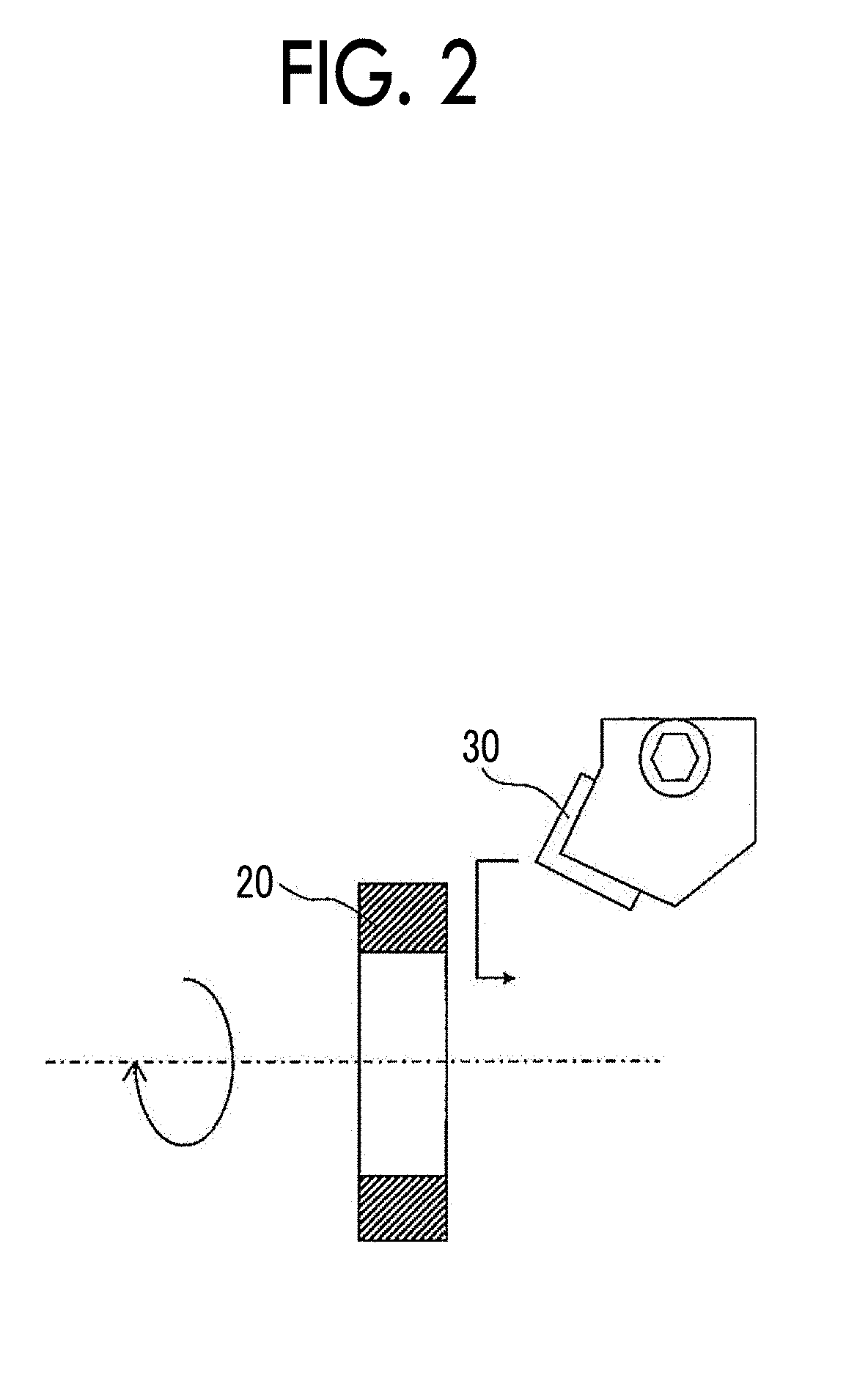

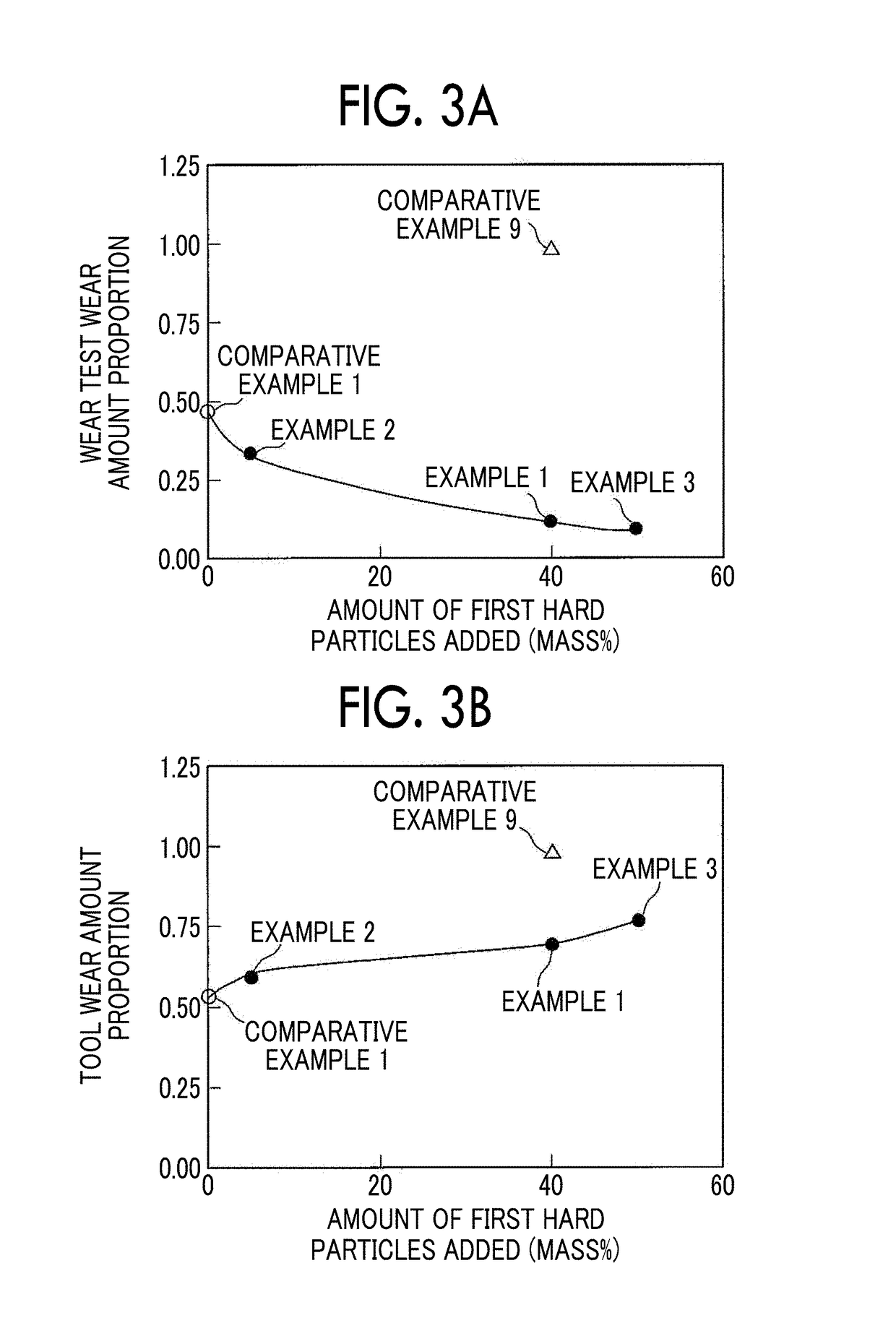

Method of producing wear-resistant iron-based sintered alloy

InactiveUS20180282844A1Secure machinabilityPrevent Adhesive WearMachines/enginesLift valveWear resistantHardness

A wear-resistant iron-based sintered alloy made of a mixed powder including first hard particles, second hard particles, graphite particles, and iron particles is produced. The first hard particles are Fe—Mo—Ni—Co—Mn—Si—C alloy particles. The second hard particles are Fe—Mo—Si alloy particles. The mixed powder includes the first hard particles at 5 mass % to 50 mass %, the second hard particles at 1 mass % to 8 mass %, and the graphite particles at 0.5 mass % to 1.5 mass % when a total amount of the above particles is set as 100 mass %. In a sintering process, sintering is performed so that the hardness of the first hard particles becomes 400 to 600 Hv and the hardness of the second hard particles exceeds 600 Hv. Then, an oxidation treatment is performed so that a density difference between before and after the oxidation treatment in a sintered product becomes 0.05 g / cm3 or more.

Owner:TOYOTA JIDOSHA KK +1

A post-tensioned self-centering steel frame structure

ActiveCN103924668BAvoid tensile crackingAvoid crackingShock proofingSteel frameUltimate tensile strength

Owner:SOUTHEAST UNIV

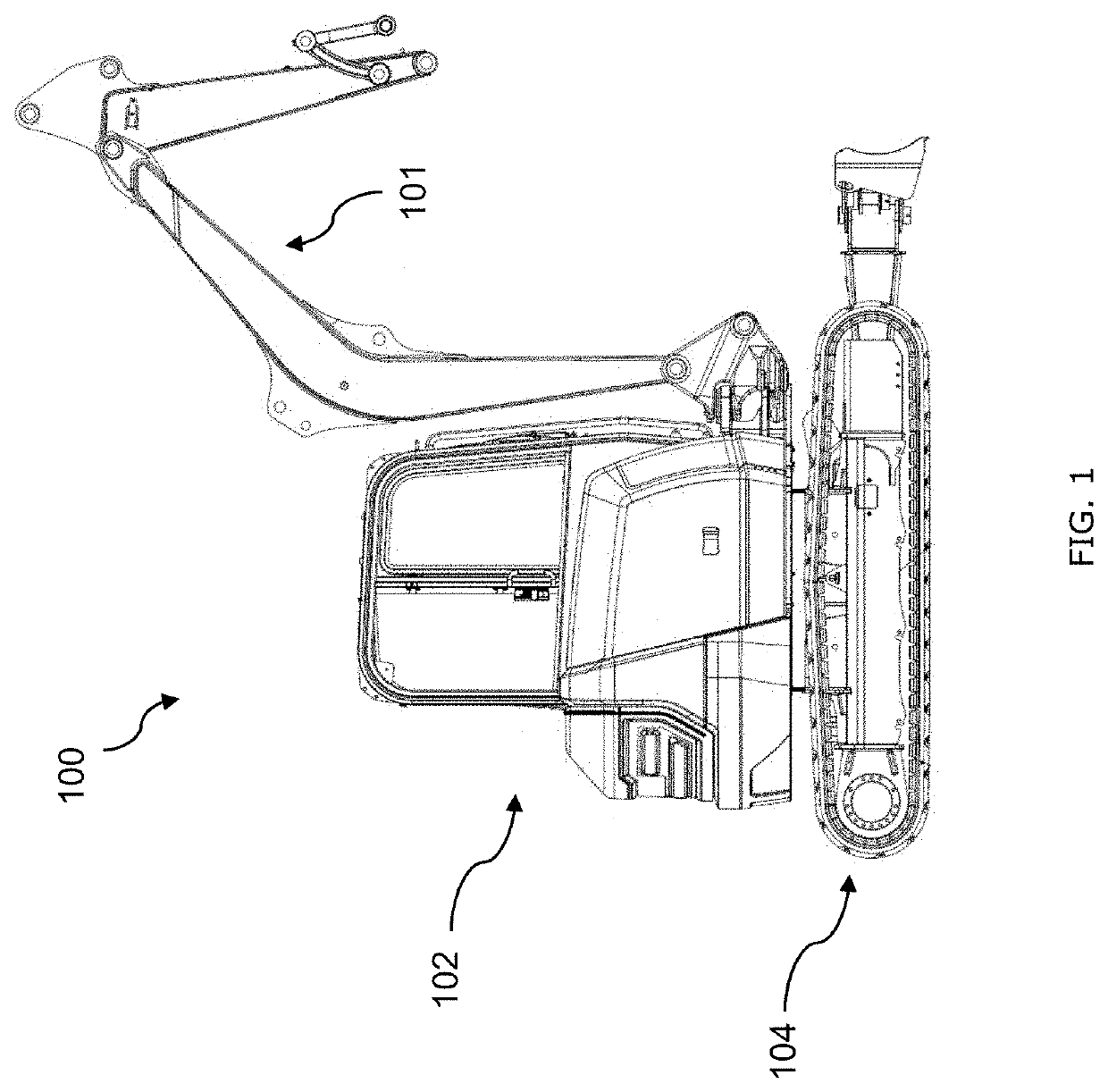

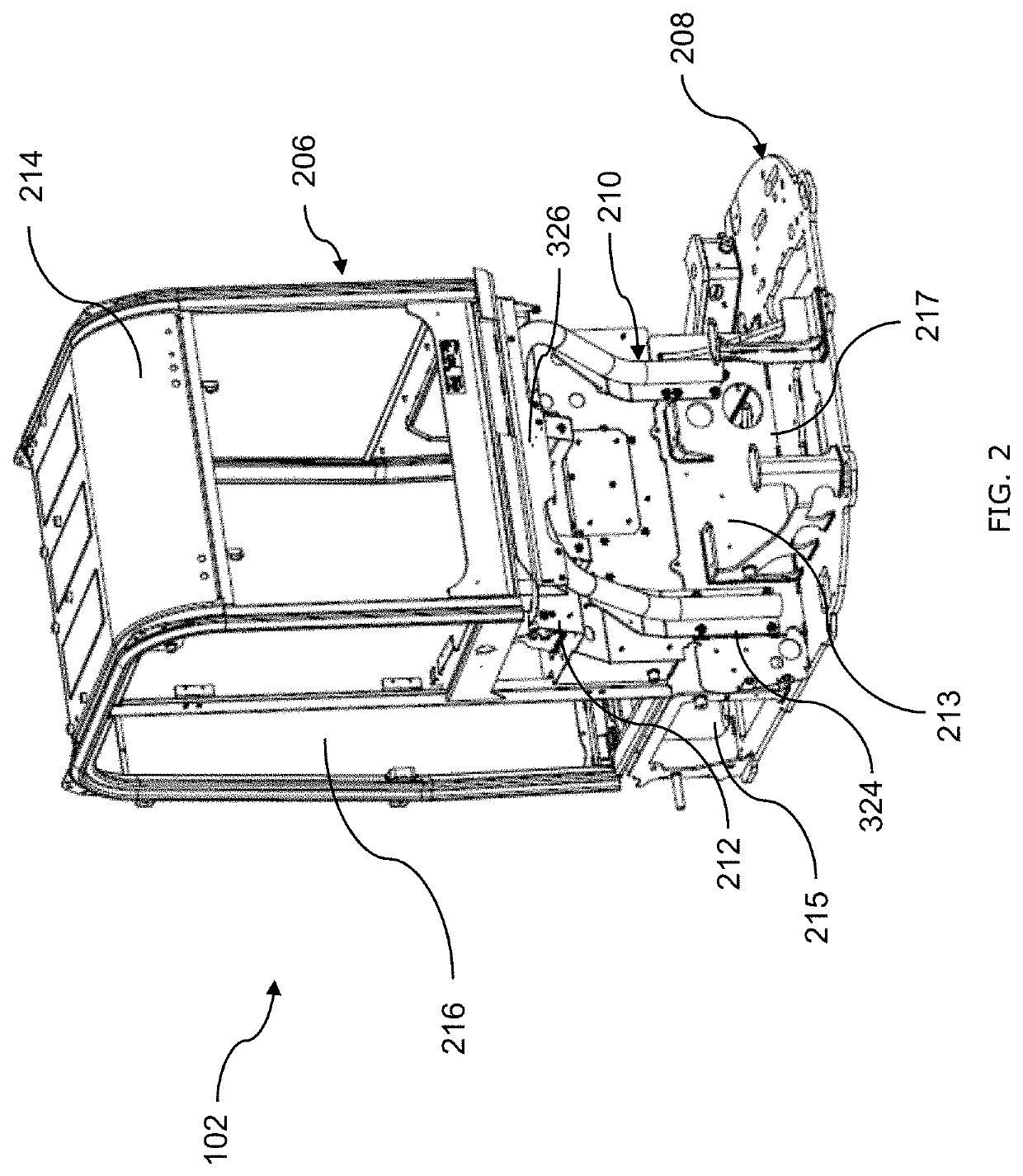

Superstructure

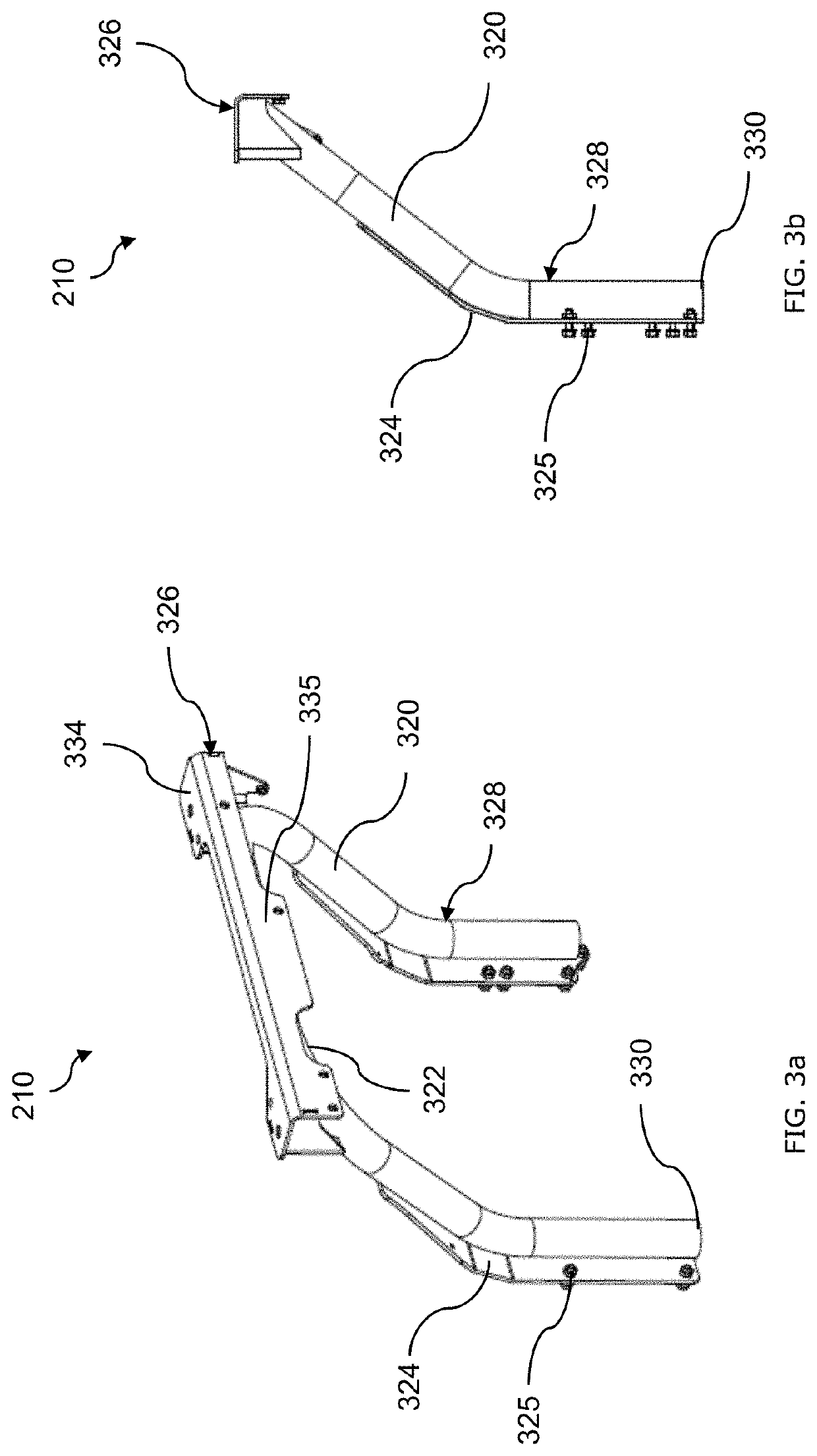

PendingUS20210230832A1Controlled plastic deformationEnsure safetyMechanical machines/dredgersEndless track vehiclesClassical mechanicsMachine

A superstructure for mounting upon a ground engaging structure of a working machine includes a cab structure for housing a human operator of the working machine; a chassis structure providing a base for the cab structure; and a frame including a tubular body, the tubular body comprising two legs and a cross member interposed between the legs, wherein the cross member is at a non-zero angle to both legs. The frame is connected to the cab structure proximate an upper extent of the frame and the chassis structure proximate a lower extent the frame so as to support a portion of the cab structure.

Owner:J C BAMFORD EXCAVATORS LTD

A plastic connection device for round pipes

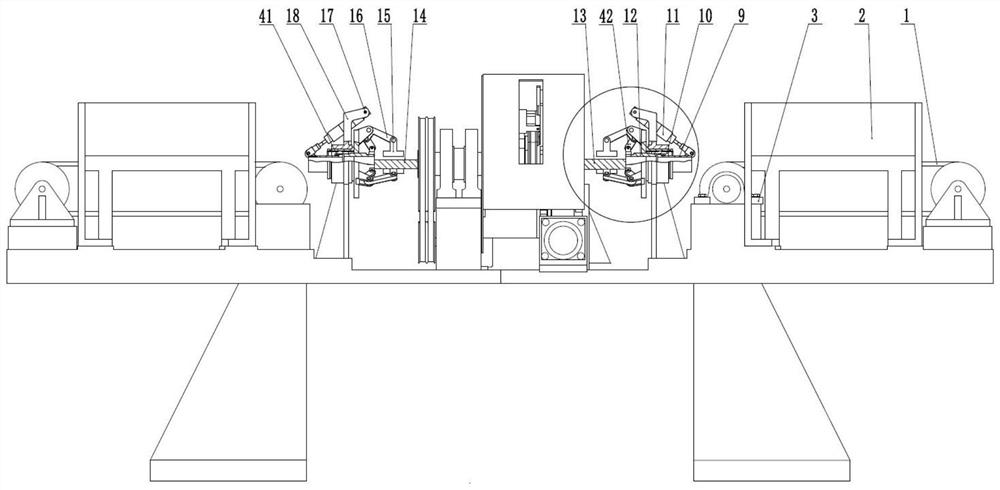

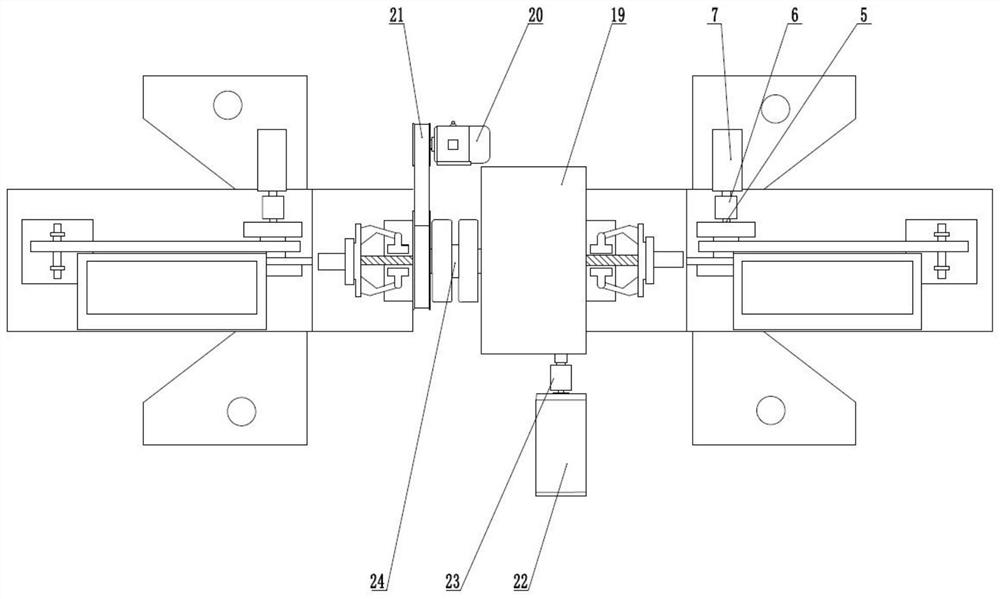

ActiveCN112571017BShorten the timeReduce deformation speedMetal working apparatusElectric machineGear wheel

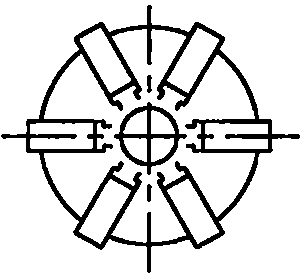

A circular pipe plastic connection device, including a feeding mechanism, a fixed clamping mechanism and a circumferential loading mechanism, through a motor and a sprocket, the rotational motion of the motor is converted into a linear feed motion of the sprocket, so that the pipe is placed in a predetermined position , further driven by the cylinder to clamp the pipe in the circumferential direction of the pressing block; driven by the motor, using the precise transmission between the gears to control the movement of the three groups of rolling devices that are opposed to each other, the movement is synchronized, and after repeated and cyclic loading; through the special pipe fixture The unique design and the use of rolling-type local progressive loading greatly improve the product's excellent performance and production efficiency.

Owner:XIAN UNIV OF TECH

A "big belly and small mouth" extrusion forming die for branch-like light alloy components

ActiveCN107639127BProcess stabilityControl stress stateExtrusion diesExtrusion mandrelsAlloyMechanical property

Owner:ZHONGBEI UNIV

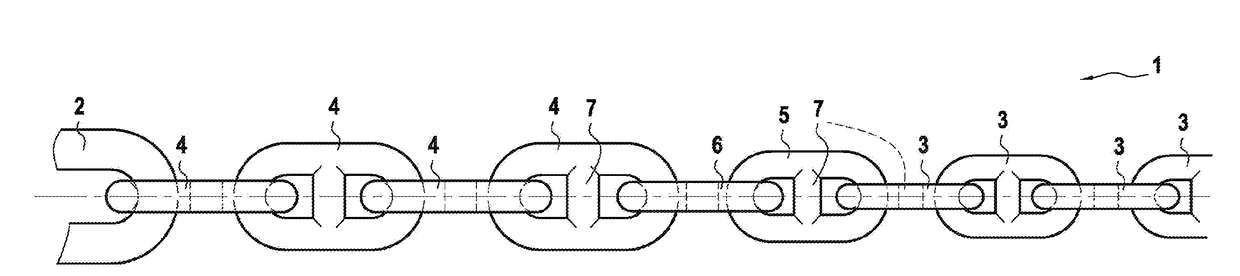

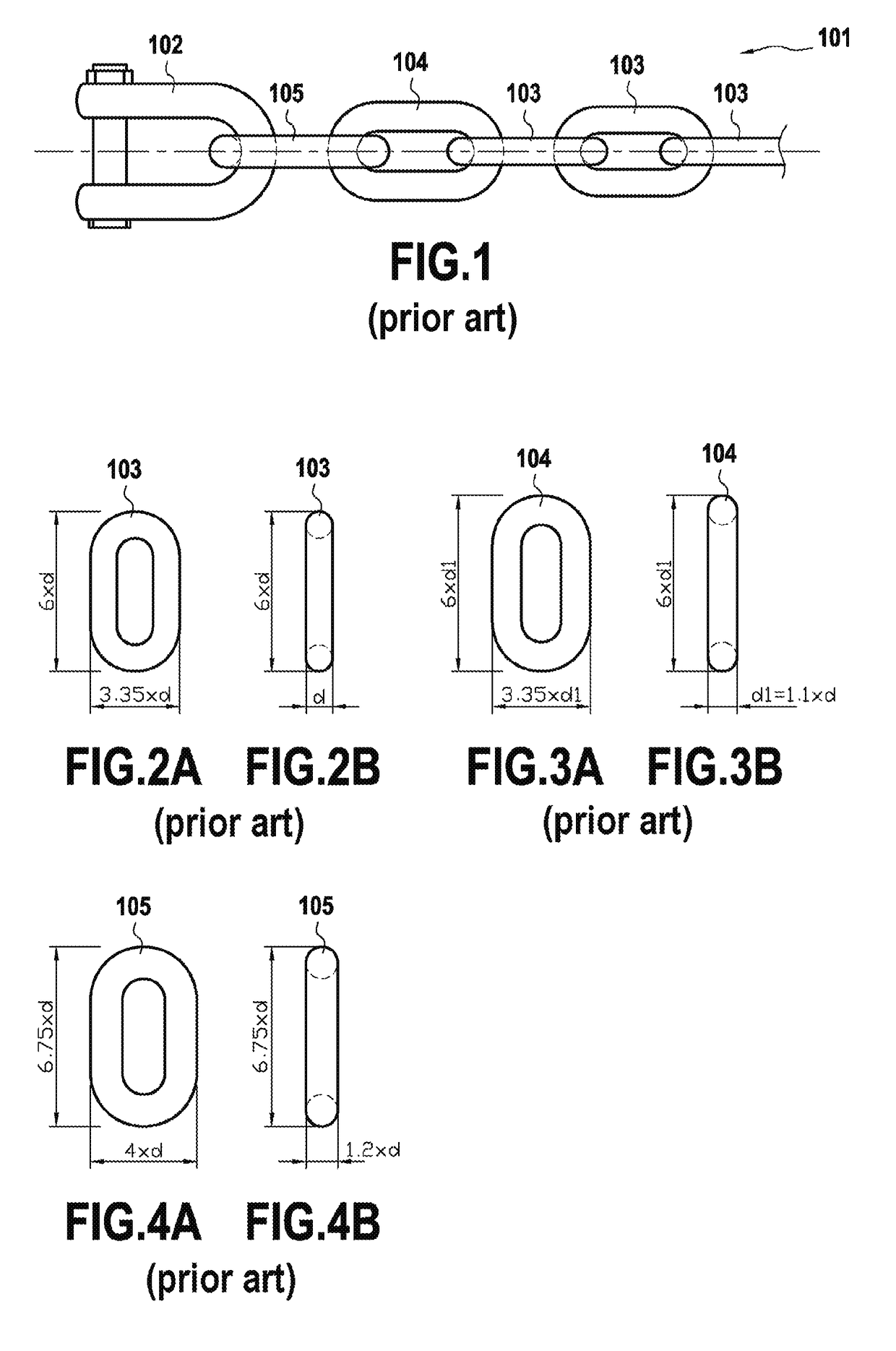

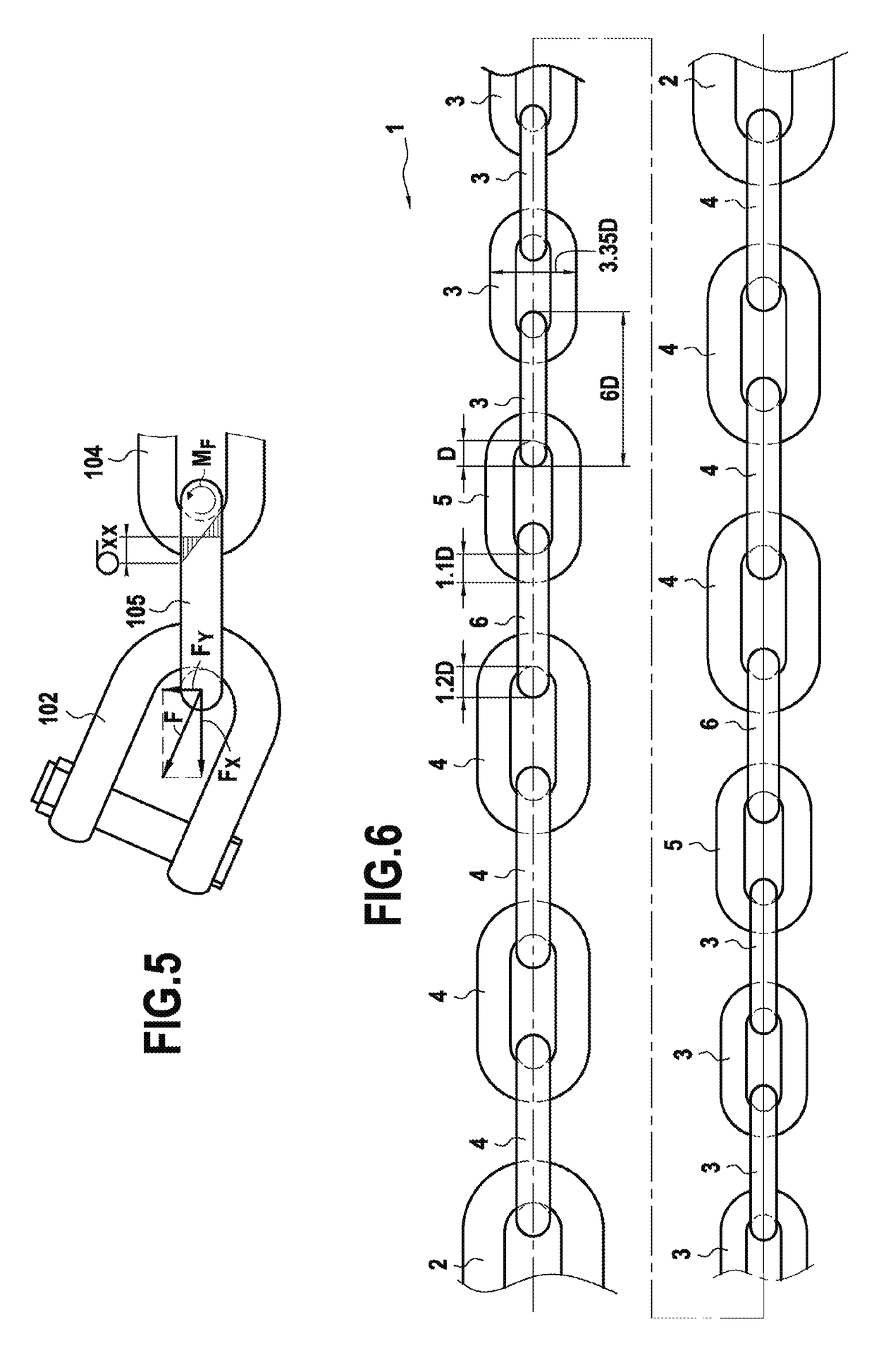

Anchor chain

Owner:IDEOL

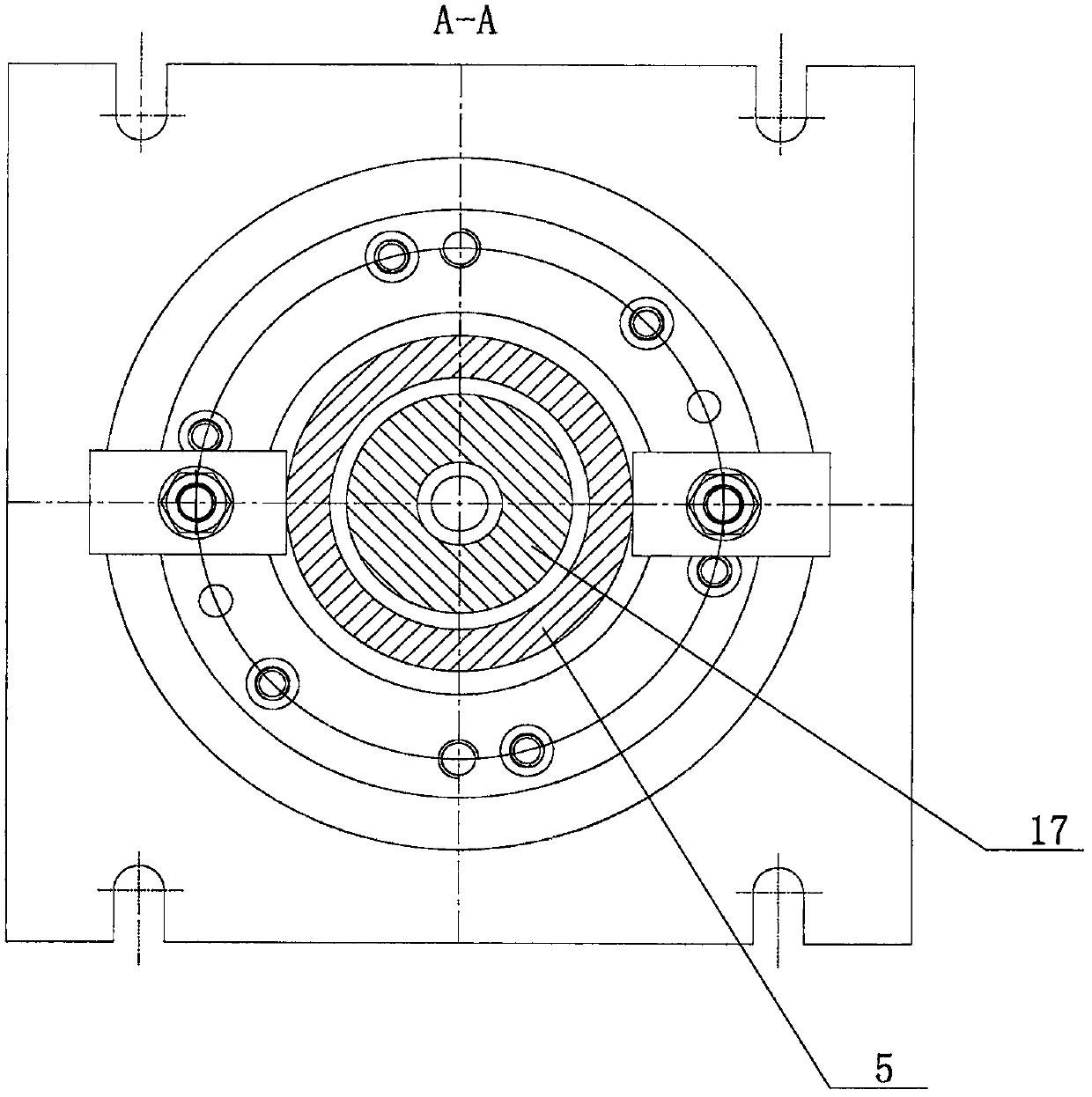

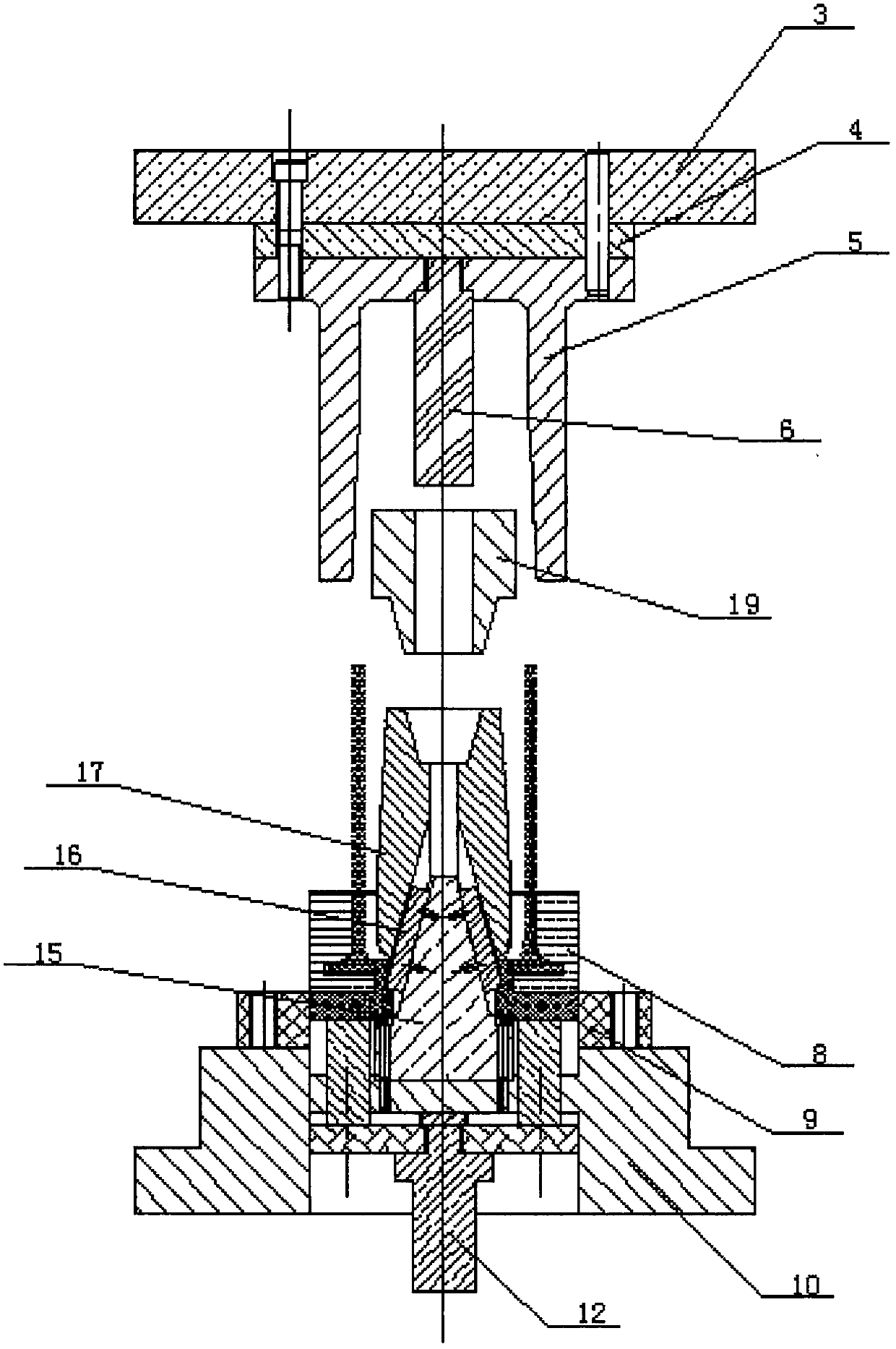

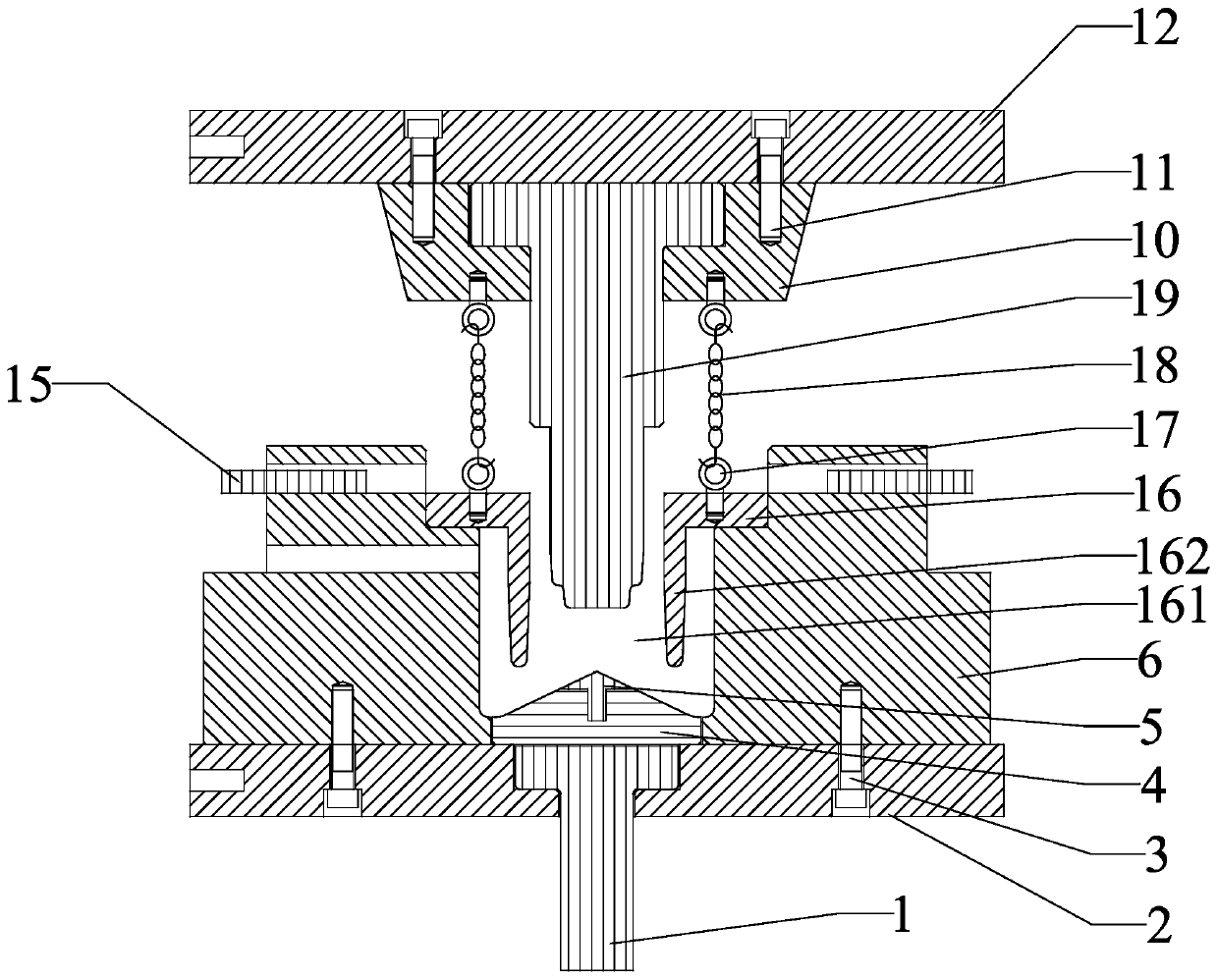

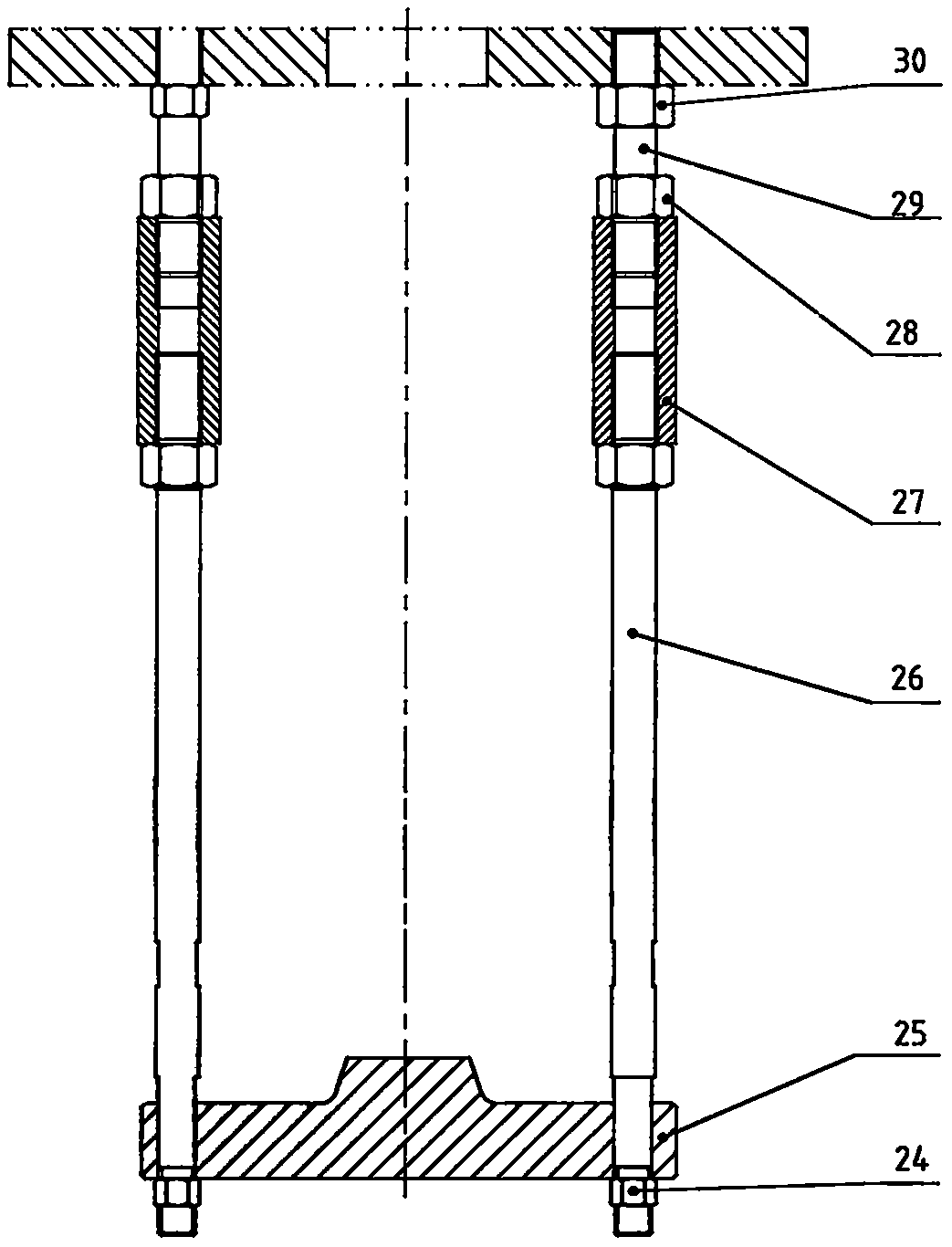

Synchronous extrusion forming mold for H-shaped steel connectors different in wall thickness

The invention discloses a synchronous extrusion molding mold for H-shaped steel connectors different in wall thickness. The mold comprises an upper mold assembly, a lower mold assembly and a guiding and jacking assembly; the upper mold assembly comprises an upper template, an embedding member, an upper mold base, a convex die, an upper mold sleeve plate, a threaded coil and a return ring; the lower mold assembly includes a lower template, a lower template pad, a lower mold support plate, a bottom core, a pressing sleeve, a shrink sleeve and a concave die; an inner flange is formed in the concave die, the concave die sleeves the upper portion of the bottom core, and the bottom core and the convex die form a transition fillet and inclination; the guiding and jacking assembly comprises a guiding column, a guiding sleeve, a jacking rod, a bottom plate, pull rods, sleeves and connecting rods. The mold adopts a warm extrusion synchronous forming method for achieving precision plastic formingof the H-shaped connectors different in wall thickness in order to effectively solve problems caused by existing conventional machining and manufacturing methods, so that the formability of alloys isimproved, the comprehensive mechanical performance of the formed connectors is improved, the utilization rate of materials is greatly increased, the production efficiency is greatly improved, energyis saved, and emissions are reduced.

Owner:ZHONGBEI UNIV

An Extrusion Forming Method of "Big Belly and Small Mouth" Type Branch Light Alloy Components

ActiveCN107552584BProcess stabilityControl stress stateExtrusion diesExtrusion mandrelsAlloyMaterials science

Owner:ZHONGBEI UNIV

Circular pipe plastic connecting device

ActiveCN112571017AShorten the timeReduce deformation speedMetal working apparatusElectric machineGear wheel

The invention discloses a circular pipe plastic connecting device. The device comprises a feeding mechanism, a fixed clamping mechanism and a circumferential loading mechanism, through a motor and a chain wheel, rotating motion of the motor is converted into linear feeding motion of the chain wheel, so that a pipe is placed at a preset position, and a pressing block is further driven by an air cylinder to circumferentially clamp the pipe; under the driving of the motor, the movement of three groups of opposite rolling devices is controlled by utilizing accurate transmission among gears, the movement is synchronous, and repeated and cyclic loading is carried out for multiple times; and due to the design of a special fixture for the pipe and the adoption of a rolling type local progressive loading manner, the excellent performance and the production efficiency of a product are greatly improved.

Owner:XIAN UNIV OF TECH

A Synchronous Extrusion Die for "h" Shaped Connectors Made of Steel with Different Wall Thickness

ActiveCN109396209BControl stress stateControl equivalent variableExtrusion diesExtrusion mandrelsStructural engineeringAlloy

The invention discloses a synchronous extrusion molding mold for H-shaped steel connectors different in wall thickness. The mold comprises an upper mold assembly, a lower mold assembly and a guiding and jacking assembly; the upper mold assembly comprises an upper template, an embedding member, an upper mold base, a convex die, an upper mold sleeve plate, a threaded coil and a return ring; the lower mold assembly includes a lower template, a lower template pad, a lower mold support plate, a bottom core, a pressing sleeve, a shrink sleeve and a concave die; an inner flange is formed in the concave die, the concave die sleeves the upper portion of the bottom core, and the bottom core and the convex die form a transition fillet and inclination; the guiding and jacking assembly comprises a guiding column, a guiding sleeve, a jacking rod, a bottom plate, pull rods, sleeves and connecting rods. The mold adopts a warm extrusion synchronous forming method for achieving precision plastic formingof the H-shaped connectors different in wall thickness in order to effectively solve problems caused by existing conventional machining and manufacturing methods, so that the formability of alloys isimproved, the comprehensive mechanical performance of the formed connectors is improved, the utilization rate of materials is greatly increased, the production efficiency is greatly improved, energyis saved, and emissions are reduced.

Owner:ZHONGBEI UNIV

Extrusion forming method of thin-walled near-contour mountain-shaped light alloy component

Owner:ZHONGBEI UNIV

A Synchronous Extrusion Forming Method for "h" Shape Connectors Made of Steel with Different Wall Thickness

ActiveCN109396208BControl stress stateControl equivalent variableExtrusion diesExtrusion mandrelsStructural engineeringMechanical engineering

The invention discloses a synchronous extrusion forming method for H-shaped steel connectors different in wall thickness. The method involves a synchronous extrusion forming mold for the H-shaped steel connectors different in wall thickness. The mold comprises an upper mold assembly, a lower mold assembly and a guiding and jacking device assembly; the method includes the steps that the mold and blanks are preheated before forming, three deformation processes are conducted during extrusion of a concave-convex die, and the connectors are guided out after final forming. The method adopts a warm extrusion synchronous forming mode for achieving precision plastic forming of the H-shaped connectors different in wall thickness in order to effectively solve problems caused by existing conventionalmachining and manufacturing methods, so that the formability of alloys is improved, the comprehensive mechanical performance of the formed connectors is improved, the utilization rate of the materialsis greatly increased, the production efficiency is greatly improved, energy is saved, and emissions are reduced.

Owner:ZHONGBEI UNIV

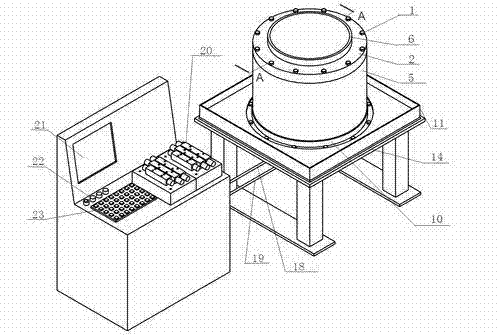

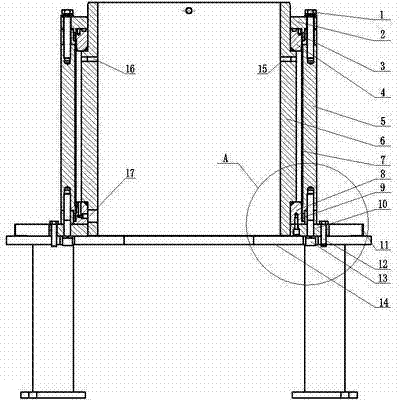

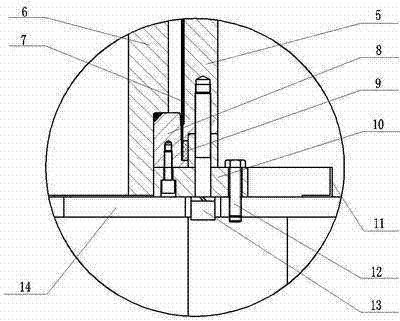

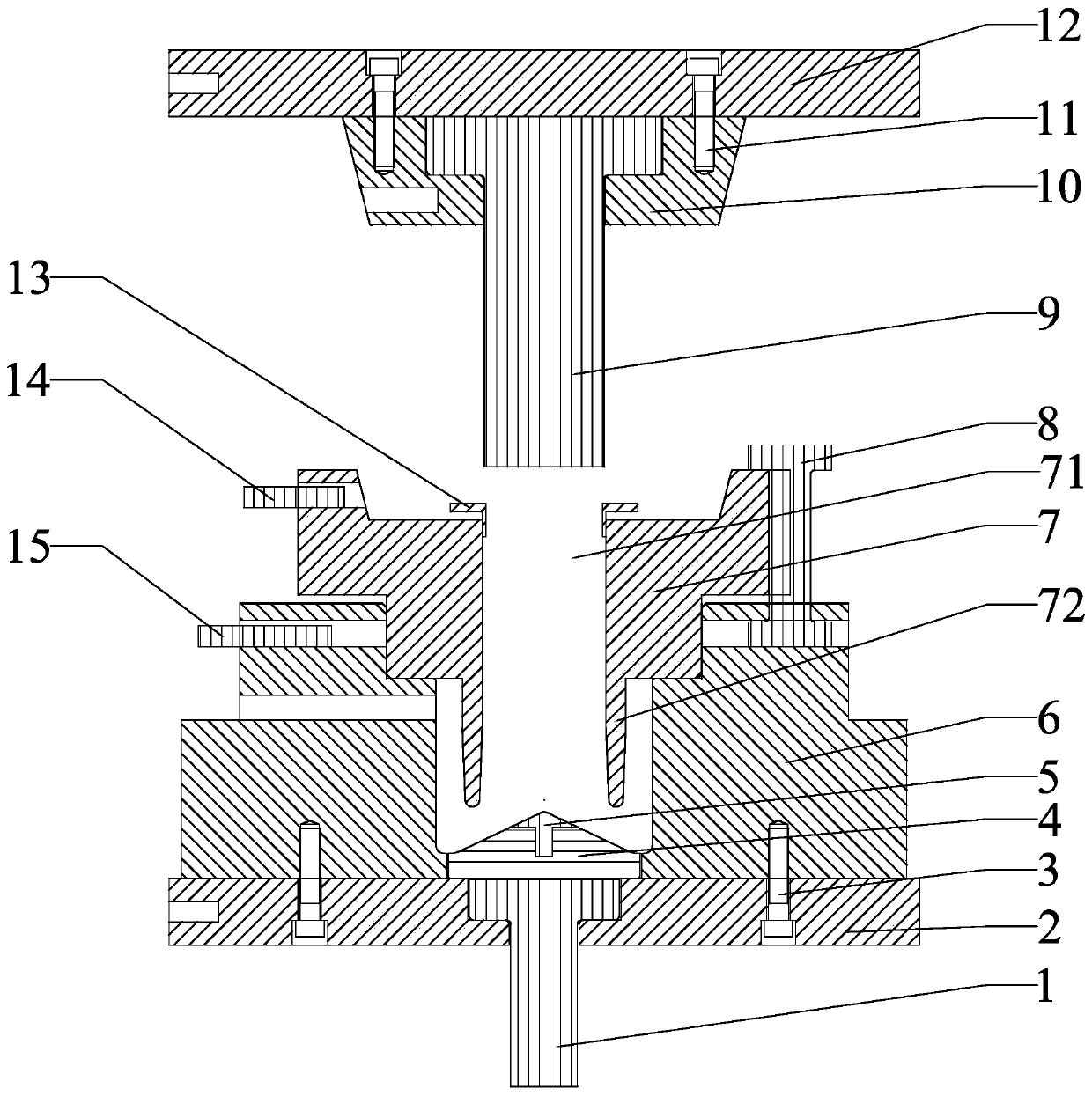

Nuclear main pump stator shield sleeve zero-clearance plasticity attachment precision assembly device

Owner:DALIAN UNIV OF TECH

Extrusion die for thin-walled light alloy component with near-contour shape

ActiveCN109530471BNo crackControl metal stress stateExtrusion diesMechanical engineeringMechanical property

Owner:ZHONGBEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com