Single use self-heating cup

a self-heating, single-use technology, applied in the direction of packaging, food packaging, packaged goods, etc., can solve the problems of unsatisfactory consumption, unfavorable consumption, and important risks, and achieve the effects of low thermal conductivity, easy forming, and excellent heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Structure of the Self-Heating Cup

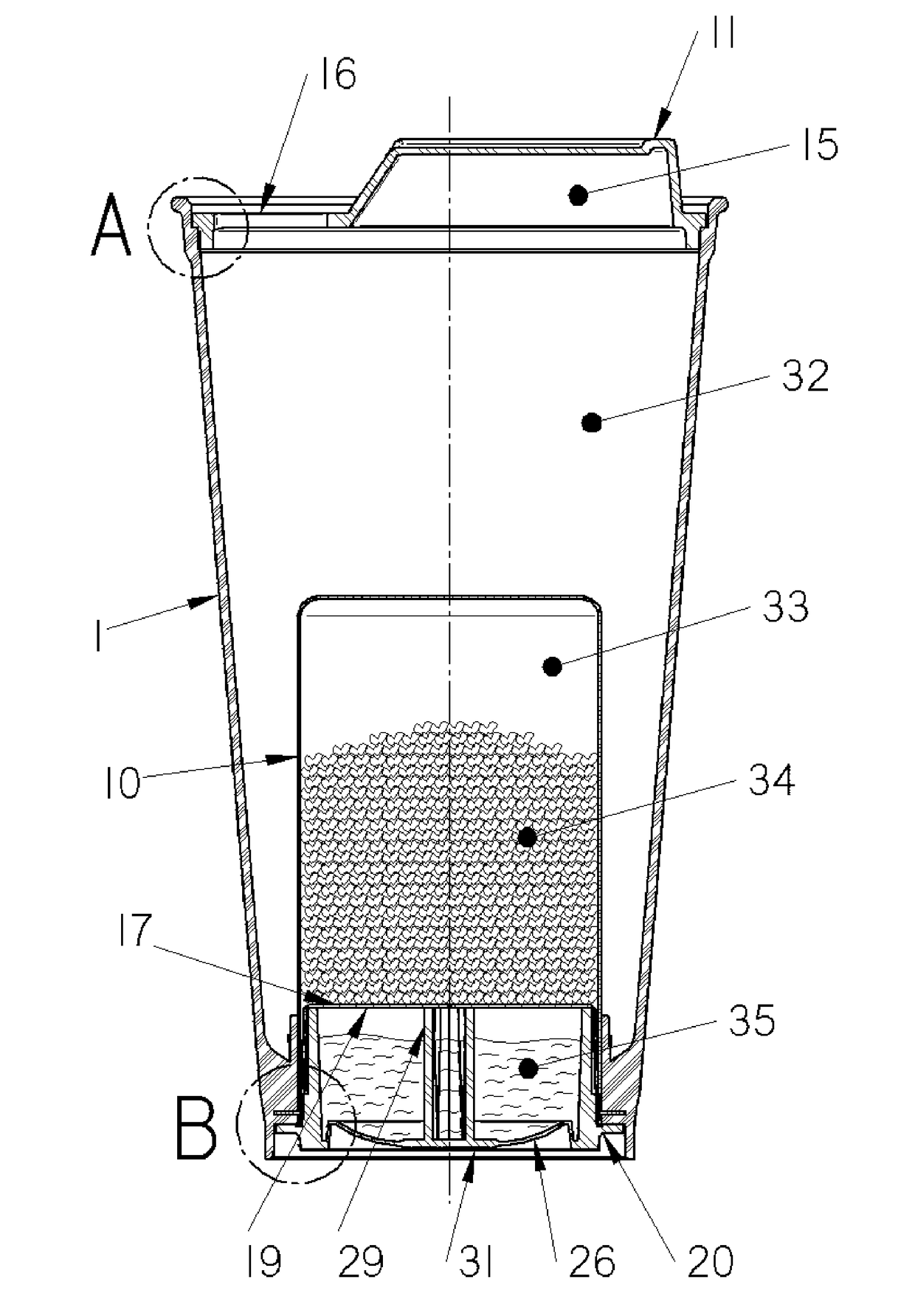

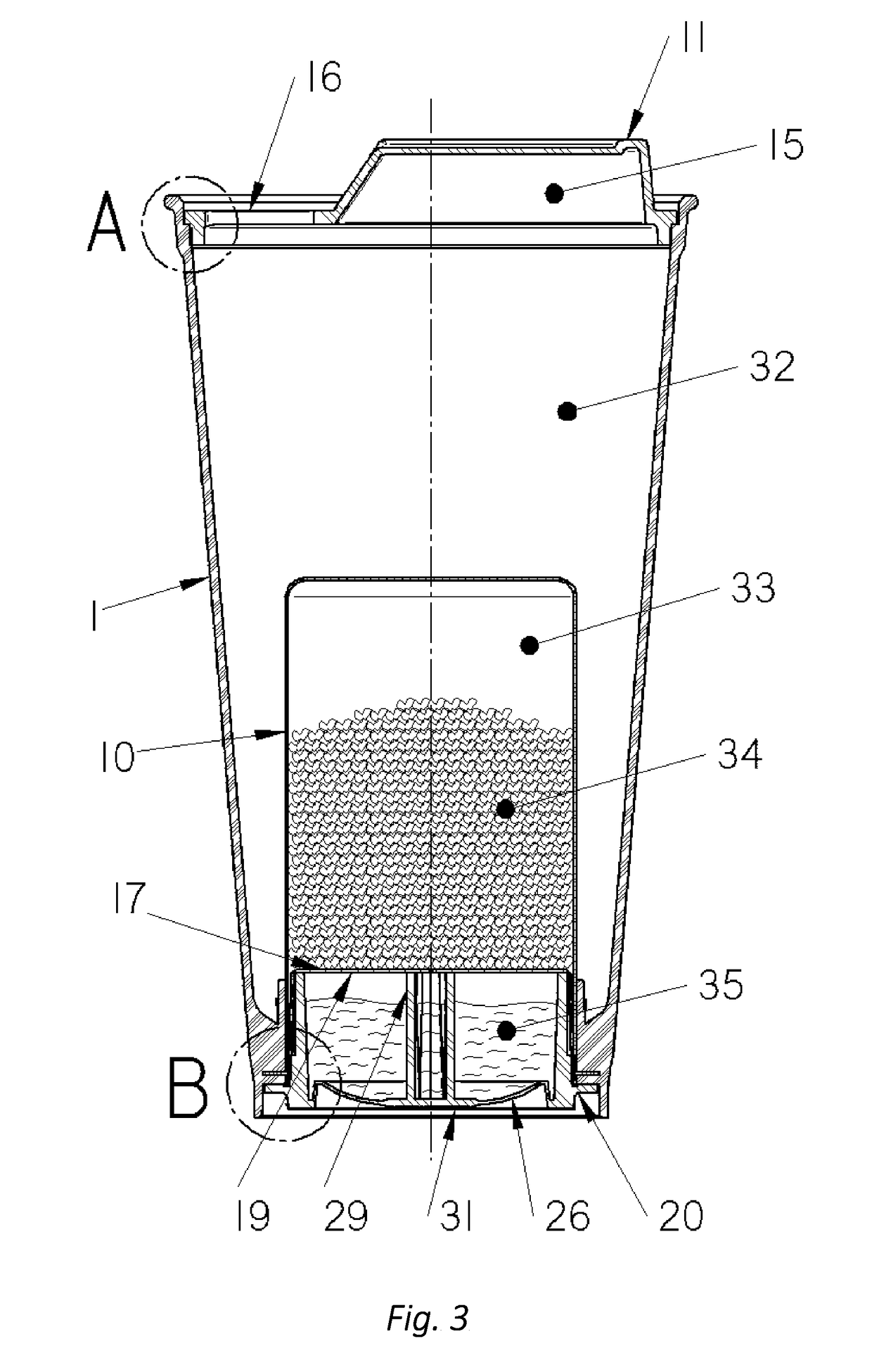

[0037]As illustrated in FIG. 5, the present invention has three major elements: container body 1, top cover 11 and the base 20 and four other parts: an upper protective foil 16, an lower protective foil 31, a breakable seal 19 and a screen 17.

[0038]The container body 1 contains the consumable product in the upper part 32, and thermal module in the lower part 33. Both of these parts are separated by a wall of aluminum alloy 10 or other metal with a high thermal conductivity to allow a quick heat transfer from reaction chamber 33 to the beverage 32. This metal wall 10 has a cylindrical shape but other forms are possible too, closed at his upper end and open to the lower end with a return bend to 90°9 to maintain it into the plastic, it may have a thickness of 0.3 to 0.8 mm. The container body 1 is obtained by plastic injection, its peculiarity of manufacture, is that injection is done over the bend 9 of aluminum cylinder 10. This operation is called ‘o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com