Extrusion moulding mold for branch type light alloy component with big middle and small ends

A technology of extrusion forming and large belly, which is used in the field of plastic processing and forming of metal materials to meet the final size and performance requirements, enhance adaptability, and internally support the effect of placing and reclaiming materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

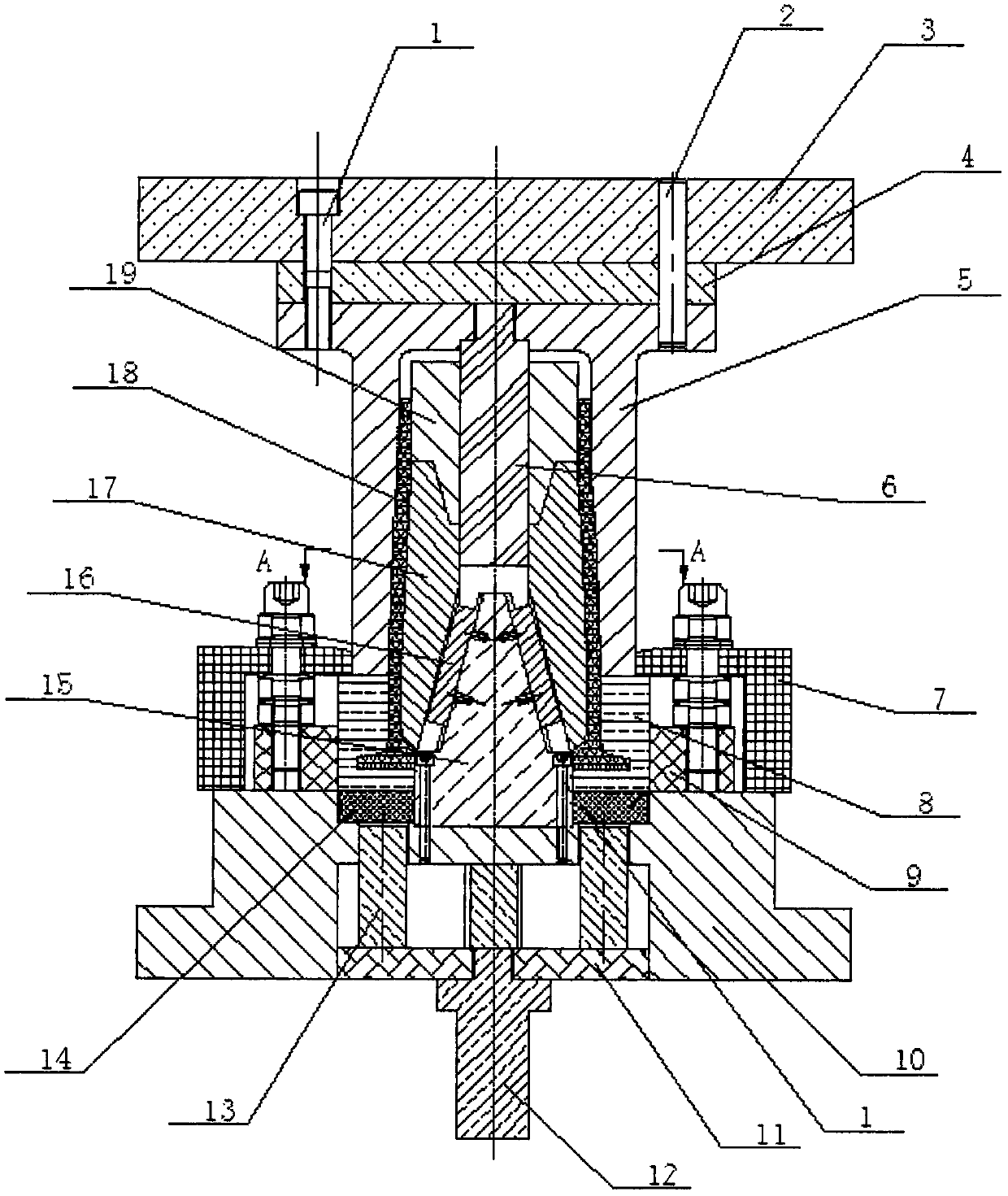

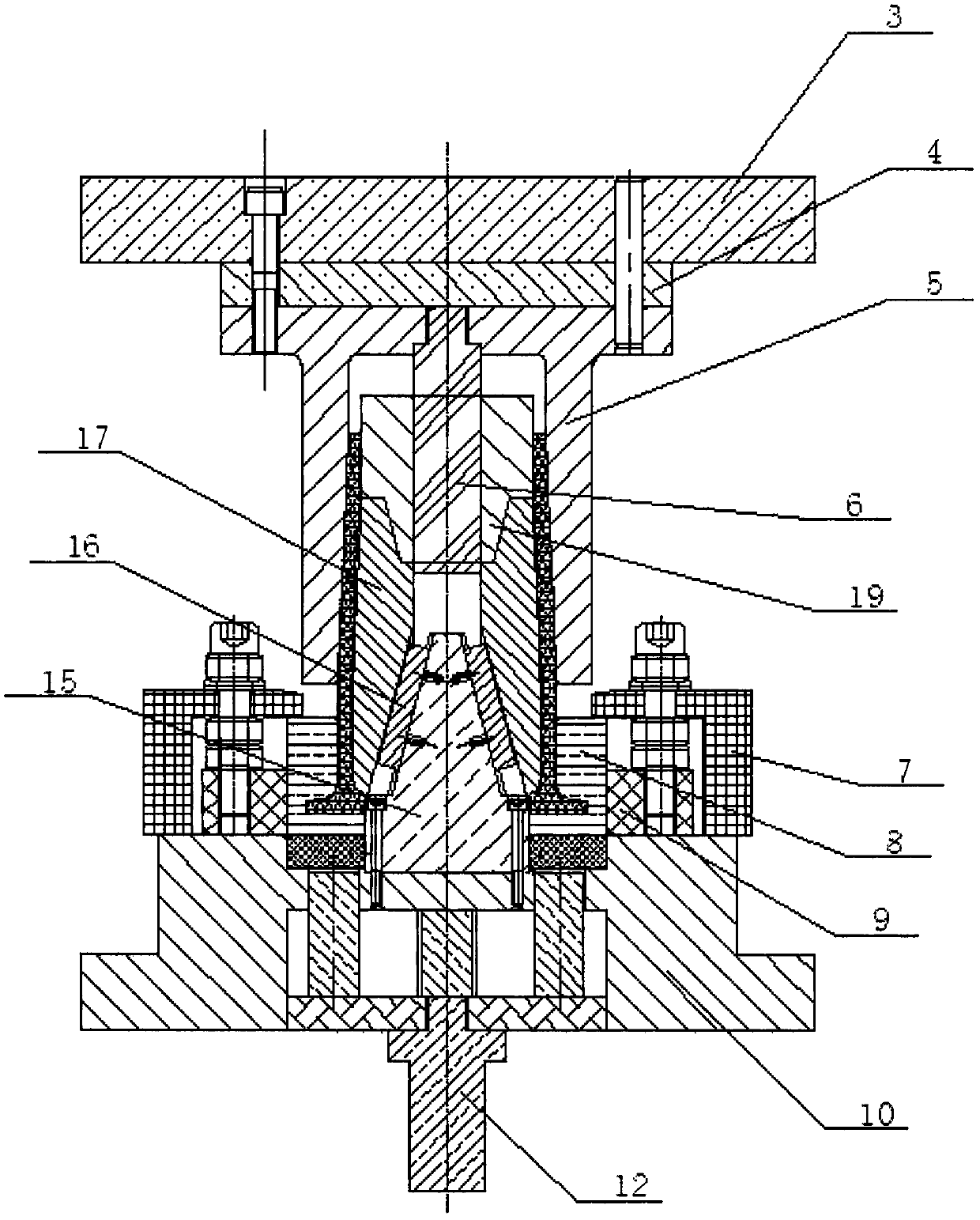

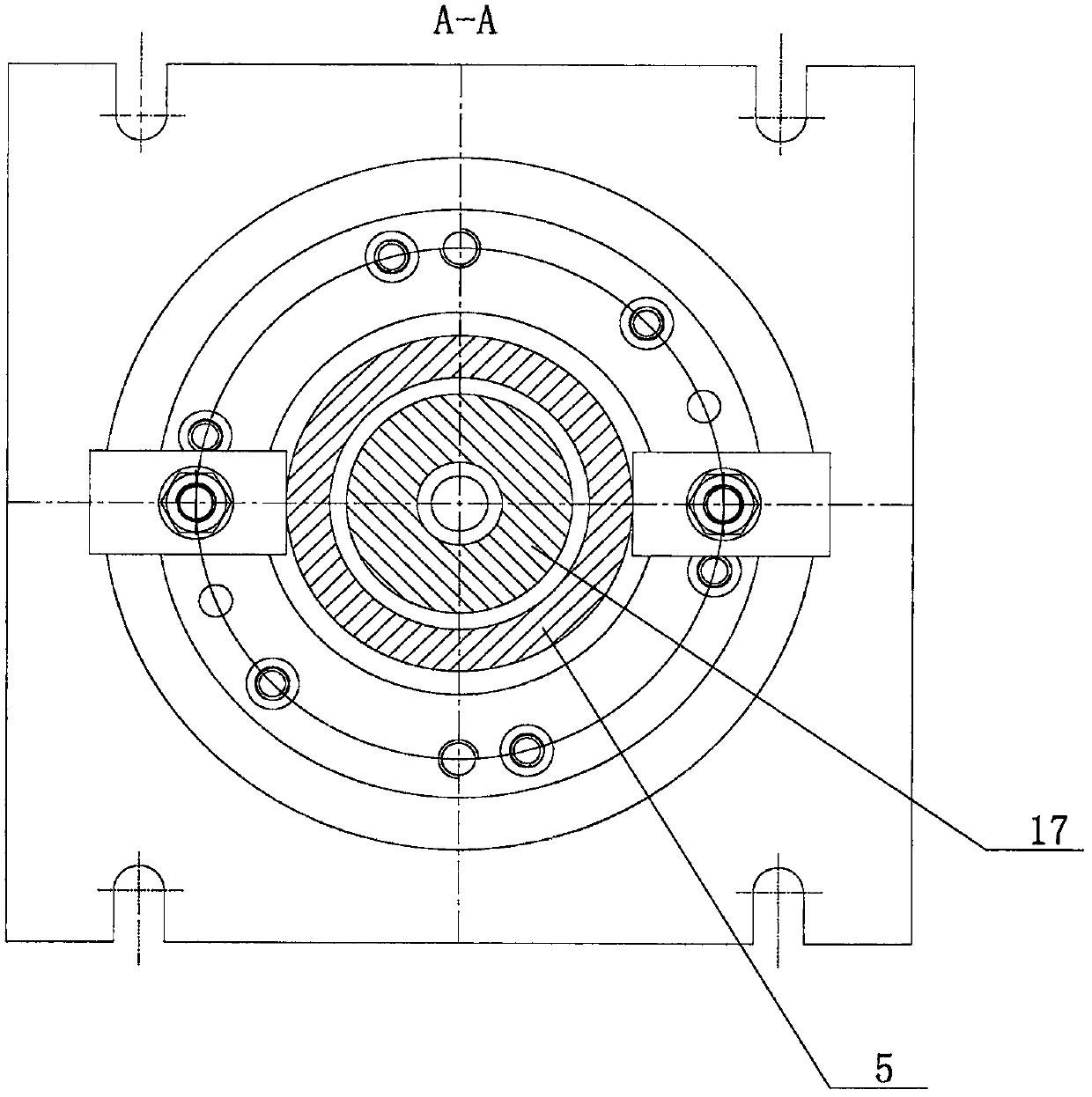

[0041] Below in conjunction with accompanying drawing, the present invention will be further described.

[0042] see Figure 1-2 As shown, the technical solution adopted in this specific embodiment is: it includes an upper mold assembly connected with the upper structure of the press, a lower mold assembly connected with the lower structure of the press, an ejector device, a feeding device 7 and a split type Internal and external support components; the upper mold component is arranged above the lower mold component; a split-type internal and external support component is arranged between the upper mold component and the lower mold component; the ejector device is located below the lower mold component, and Clearance fit connection; the top of the ejector device is in contact with the split inner and outer supports, and the end is connected with the ejector cylinder; the feeding device is fixed above the lower mold assembly, and is located between the upper mold assembly and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com