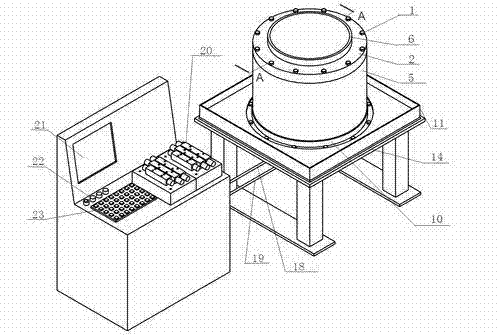

Nuclear main pump stator shield sleeve zero-clearance plasticity attachment precision assembly device

A technology for assembling equipment and shielding sleeves, which is applied in the field of nuclear power, can solve the problems of aggravating the unevenness of shielding sleeve thickness deformation, the inability to perform precise assembly, and the inability to complete assembly, so as to achieve seamless plastic deformation attachment, save materials, and avoid The effect of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

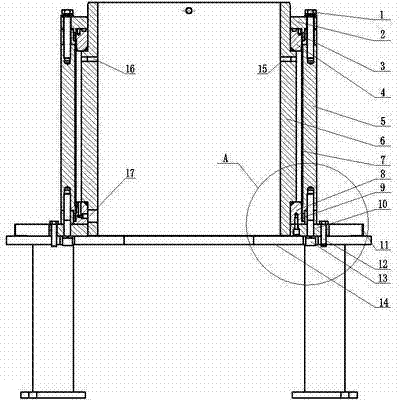

[0027] figure 1 As shown in Fig. 2, the lower end cover 10 is fixed on the assembly platform 14 through the lower bolt assembly 13 and the fixing bolt 12, the lower support ring 8 is fixed on the lower end cover 10 through the set screw, and the support cylinder 6 passes through the lower support ring 8 and the lower end The center hole of the cover 10 is embedded on the component stand 14, the stator shielding sleeve 7 is fixed on the outer surface of the lower support ring 8 under the joint action of the lower support ring 8 and the lower sealing ring 9, the stator core model 5 passes through the lower end cover 10, the lower bolt The component 13 is fixed on the lower end cover 10, the upper support ring 4 is sleeved on the support tube 6 through its center hole, and the upper end cover 2 and the support tube 6 are connected with the stator core model 5 through the upper bolt assembly 1 .

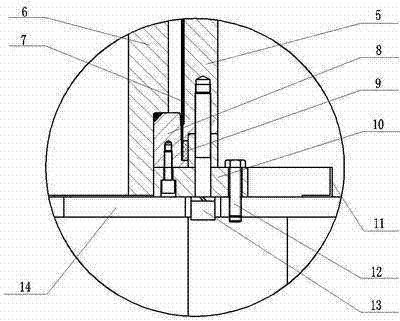

[0028] Figure 3 is a partial enlarged view of structure A in Figure 2.

[0029] Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com