Annular embedded part structure of nuclear power station dry protection equipment and mounting method

A technology for protecting equipment and installation methods, applied in building structures, buildings, etc., can solve the problems of long construction period occupied by critical paths, high risk of construction safety operations, and narrow welding operation space, so as to shorten the construction period and reduce the cross construction time. , the effect of small temperature gradient of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Taking the installation and construction of the ring-shaped embedded parts of the No. 4 nuclear island dry protection equipment used in the Tianwan Nuclear Power Phase II nuclear power project as an example, the specific explanation of the embodiment of the present invention is as follows:

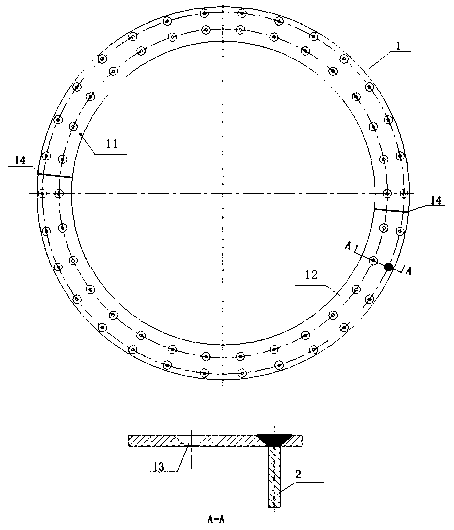

[0079] refer to figure 1 , the equipment embedded part of the present invention is composed of three parts: the first ring plate (11) and the second ring plate (12) and the anchor bar, the lower end of the equipment embedded part is anchored in the core concrete through the anchor bar 2, and forms a A solid whole with dry protection equipment installed on the upper part.

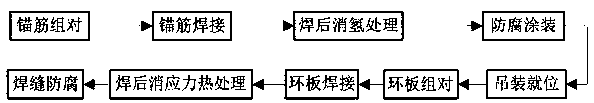

[0080] For the installation and construction process of the dry protection equipment annular embedded parts figure 2 , including the following steps:

[0081] (1) Anchor reinforcement pair:

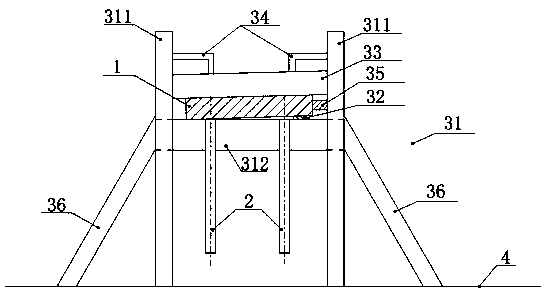

[0082] ① Manufacture of integral rigid formwork

[0083] Design a dedicated integral rigid formwork 3, the rigid formw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com