Nuclear power plant containment steel lining integrated connection module structure and its installation method

A nuclear power plant containment and connection module technology, applied in the field of construction, can solve the problems of long construction time, narrow welding operation space, high risk of high-altitude operation, etc., and achieve the effect of reducing the height of high-altitude operation, easy operation, and reducing the risk of installation operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

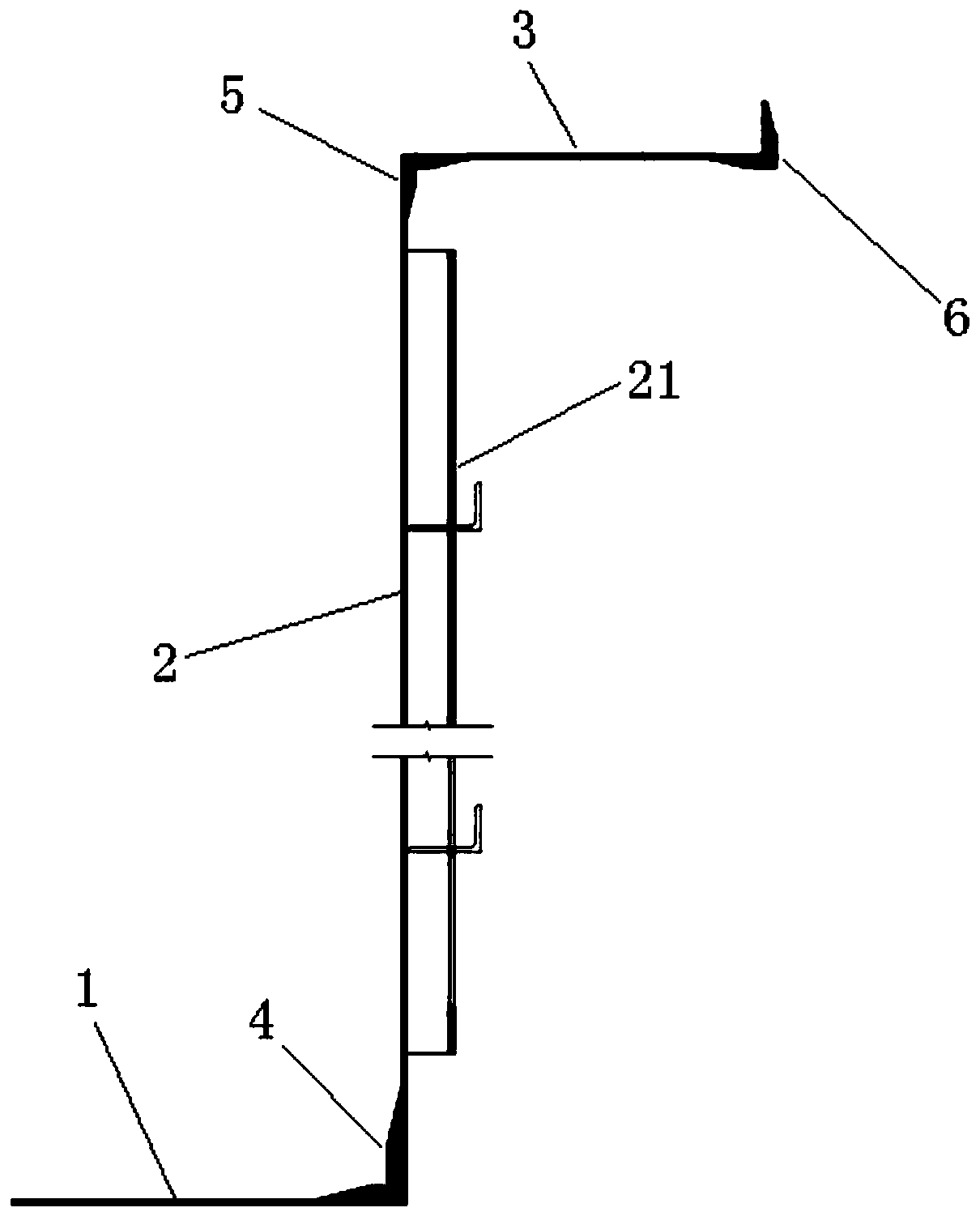

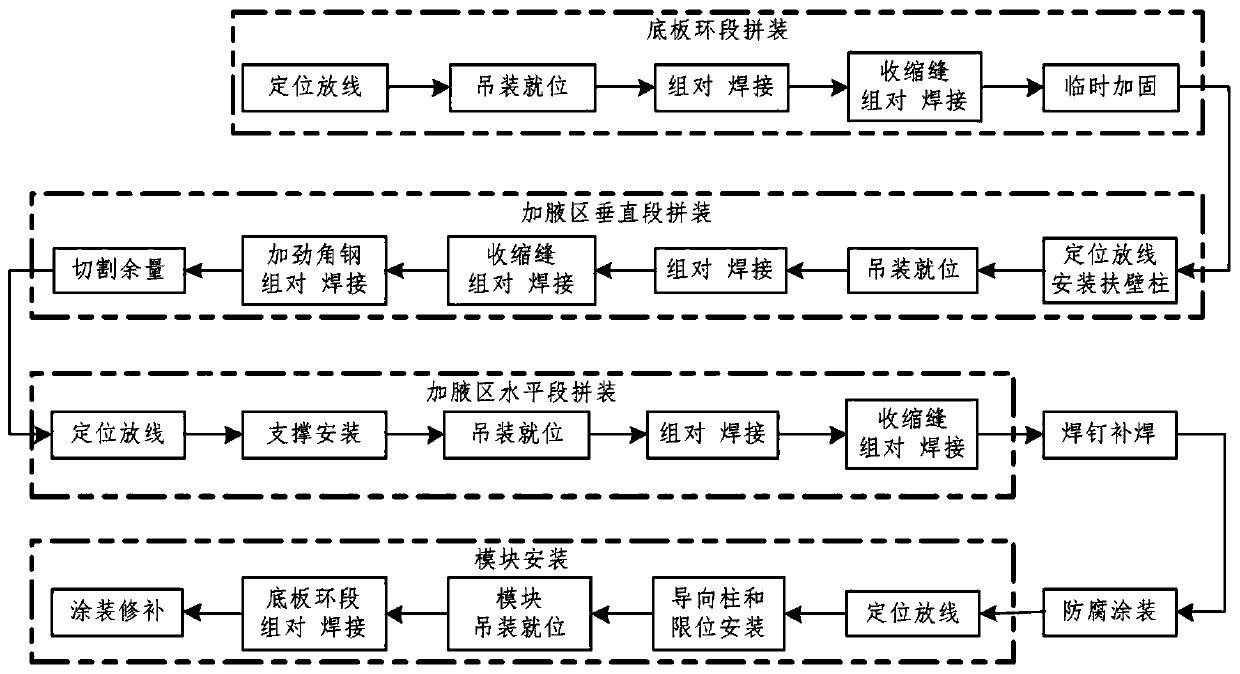

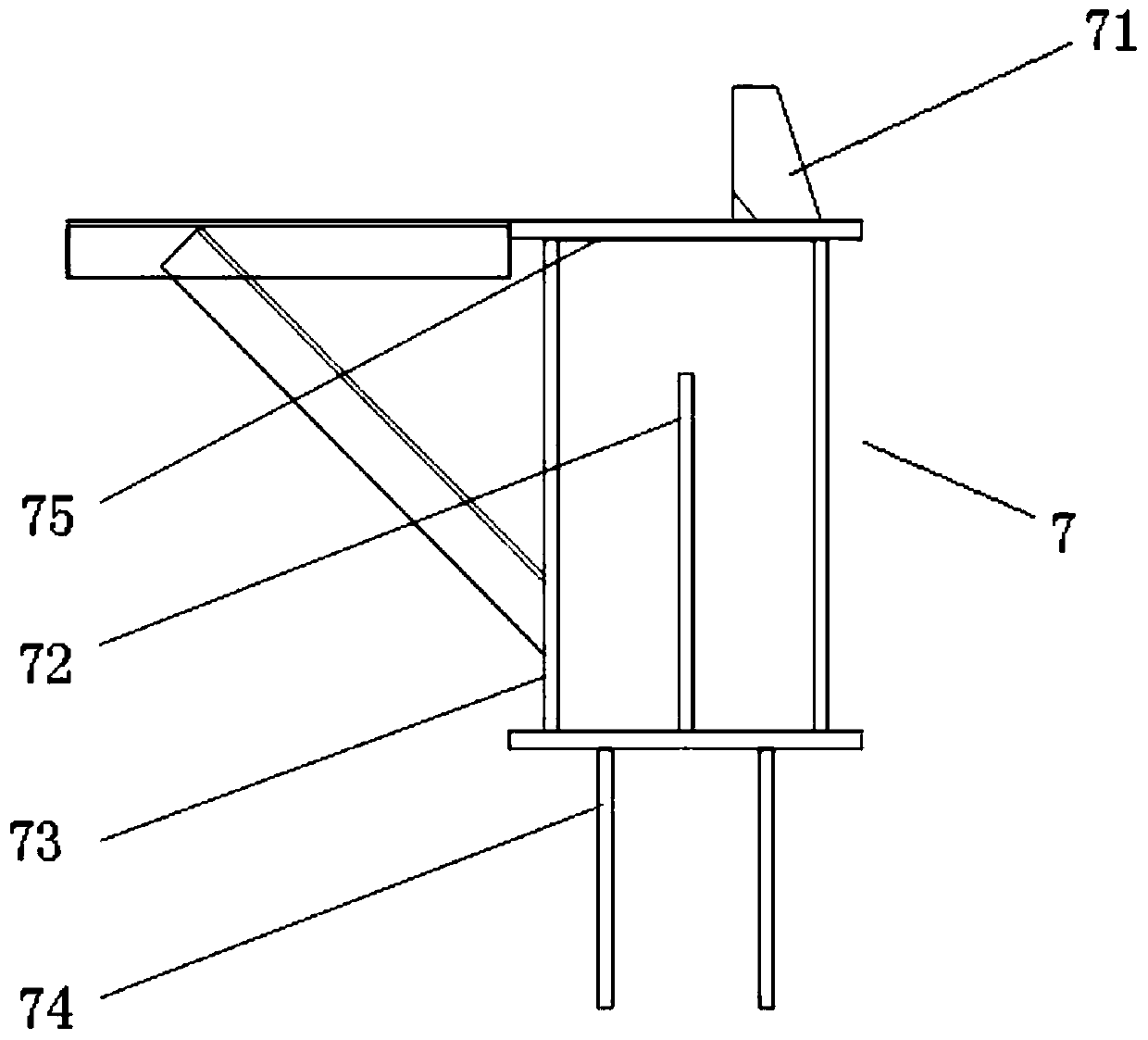

[0044] The module of the present invention is composed of three parts-the bottom plate ring section, the vertical section and the horizontal section, including the first, second, and third reinforcement nodes. The upper and lower parts of the module are respectively connected with the first layer of the steel lining cylinder and the bottom plate, as a containment A part of the steel lining acts as a link between the preceding and the following.

[0045] The invention solves the problems of narrow welding operation space for on-site installation of the armpit area and the bottom plate ring section, difficulty in positioning the module, long construction time intersecting with the inner shell, high risk of high-altitude operation, and long construction period of the special key path. Adopt the present invention, assemble into module at assembling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com