Rail transit engineering shallow-buried interval prefabricated laminated structure and construction method thereof

A technology of rail transit engineering and construction method, which is applied in the field of prefabricated laminated structure and its construction in the shallow buried section of rail transit engineering, which can solve the problem of difficulty in guaranteeing the quality of bored piles, time-consuming waiting for the strength of cast-in-place piles, and unfavorable sustainability Development and other issues, to achieve the effect of improving industrialization efficiency and construction speed, avoiding maintenance time, and avoiding construction waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

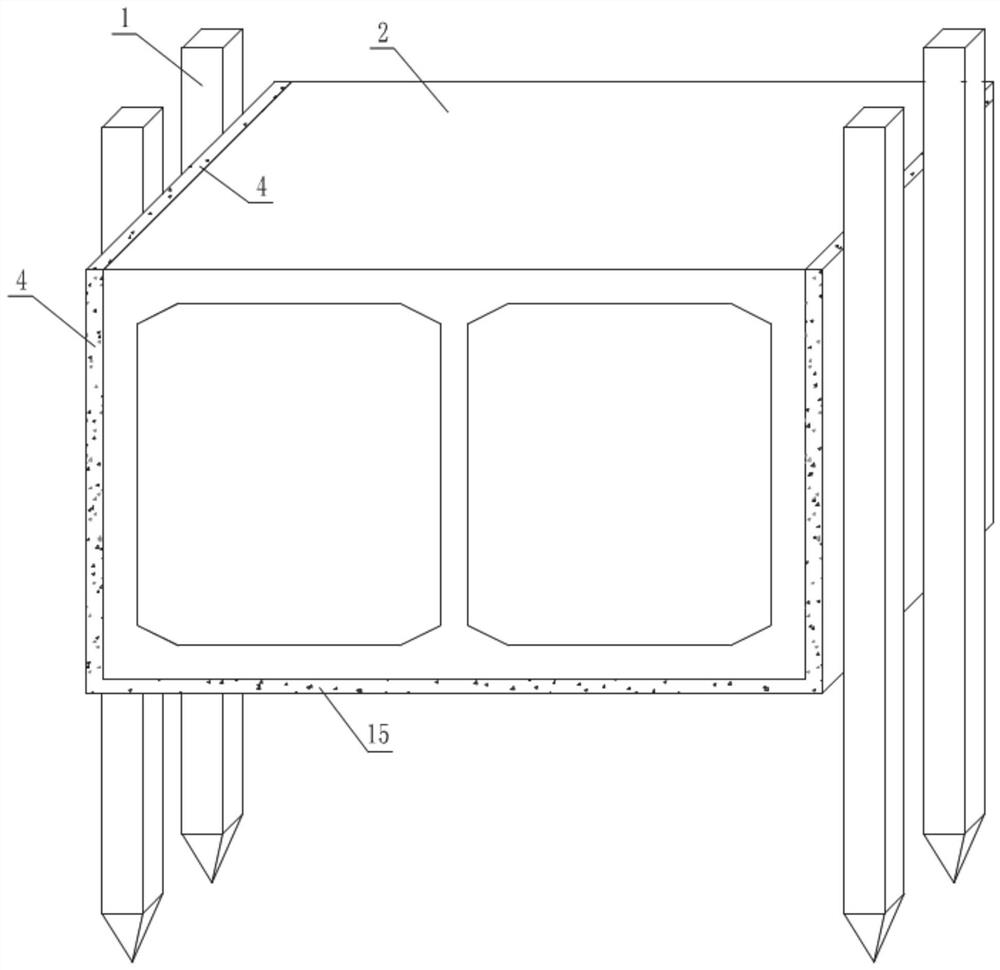

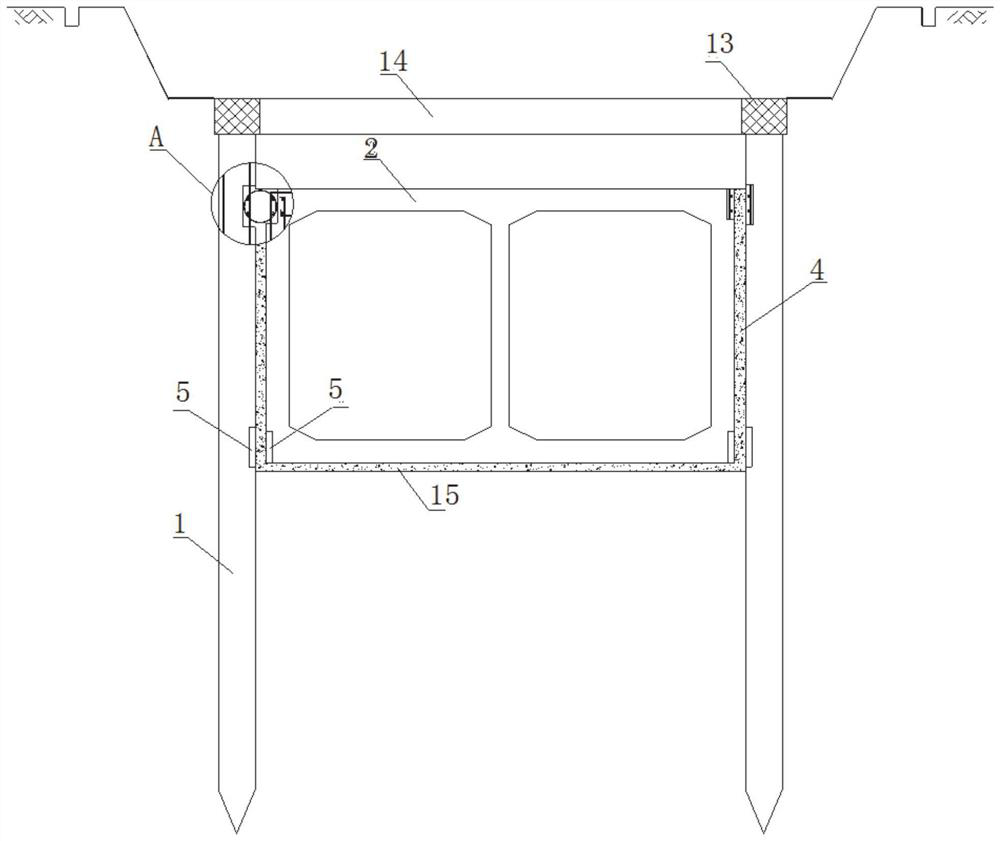

[0040] In a typical implementation of the present disclosure, such as Figure 1-Figure 6 As shown in the figure, a prefabricated superimposed structure for the shallow buried section of rail transit engineering is proposed.

[0041] It mainly includes box culverts and prefabricated piles. The prefabricated piles are distributed on both sides of the box culvert. Each side of the box culvert is matched with multiple prefabricated piles arranged at intervals. protection structure, and the box culvert is the main structure of the interval;

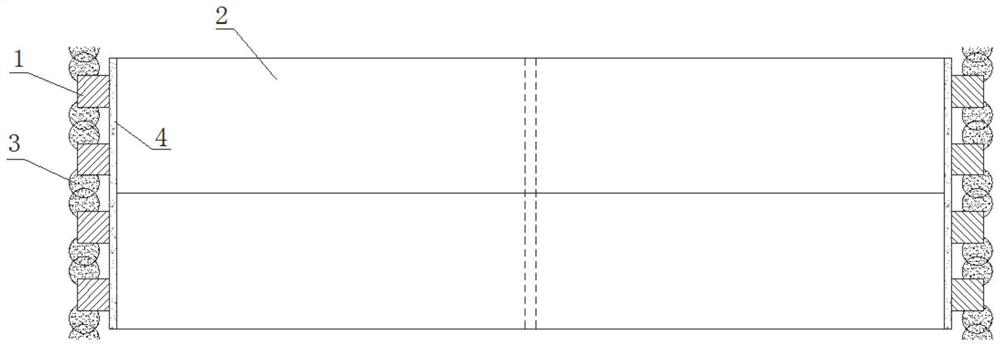

[0042] In this embodiment, the box culvert is a prefabricated rectangular box culvert structure, and the prefabricated piles are prefabricated square piles; Rotary grouting pile 3, the two interlock to form a continuous enclosure structure;

[0043] The shallow-buried section structure adopts prefabricated square piles and prefabricated rectangular box culvert components to realize industrialization, industrialization, and refinement, and ov...

Embodiment 2

[0068] In another typical implementation of the present disclosure, such as Figure 1-Figure 6 As shown, a construction method for prefabricated laminated structures in shallow buried sections of rail transit projects is proposed.

[0069] Include the following steps:

[0070] Carry out site leveling and survey positioning, drill holes and inject cement-soil mud retaining walls, and position prefabricated piles at the designed positions;

[0071] According to the construction position, the prefabricated piles are placed in the design position, and the triple tube high-pressure rotary spraying is used between the prefabricated piles to make the high-pressure rotary spraying pile water-stop curtain;

[0072] Excavate the shallow buried section to the bottom elevation of the crown beam, apply concrete slope protection, and then construct the crown beam;

[0073] Excavate the foundation pit step by step until the design elevation of the foundation is reached, and a cushion is ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com