A prefabricated pipeline loading and unloading transportation auxiliary device

A technology for auxiliary devices and prefabricated parts, applied in the directions of transportation and packaging, hoisting devices, lifting devices, etc., can solve the problems of inconvenient loading and unloading of cement prefabricated pipes, and achieve the effects of solving inconvenient loading and unloading, reasonable structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

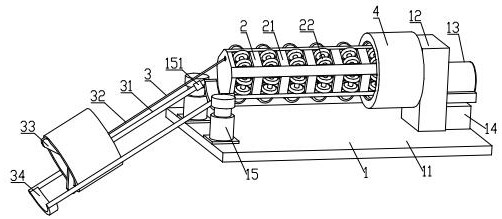

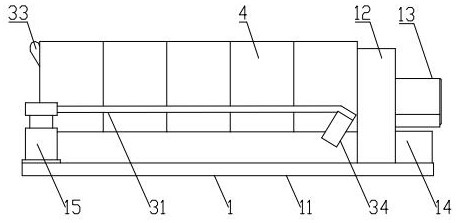

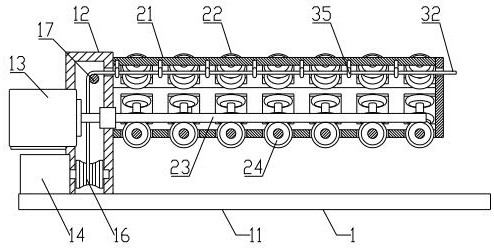

[0031] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0032] like Figures 1 to 10 A prefabricated auxiliary device for loading, unloading and transportation of pipelines is shown, which includes a power base 1, a fixed support frame 2, and a telescopic loading and unloading frame 3. The power base 1 includes a connection base plate 11, a power box 12, a first motor 13, a second Two motors 14, electric cylinders 15, reels 16 and guide rods 17.

[0033] like figure 1 As shown, the connecting bottom plate 11 has a rectangular structure, and the connecting bottom plate 11 is fixedly connected to a transport vehicle. The transport vehicle mentioned here includes but is not limited to a construction site trolley and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com