Multipurpose shoe box for high heels

A high-heeled shoe, multi-functional technology, applied in the field of daily life, can solve the problems of shoe damage, shoes bumping against each other, scratches on the surface of shoes, etc., to achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

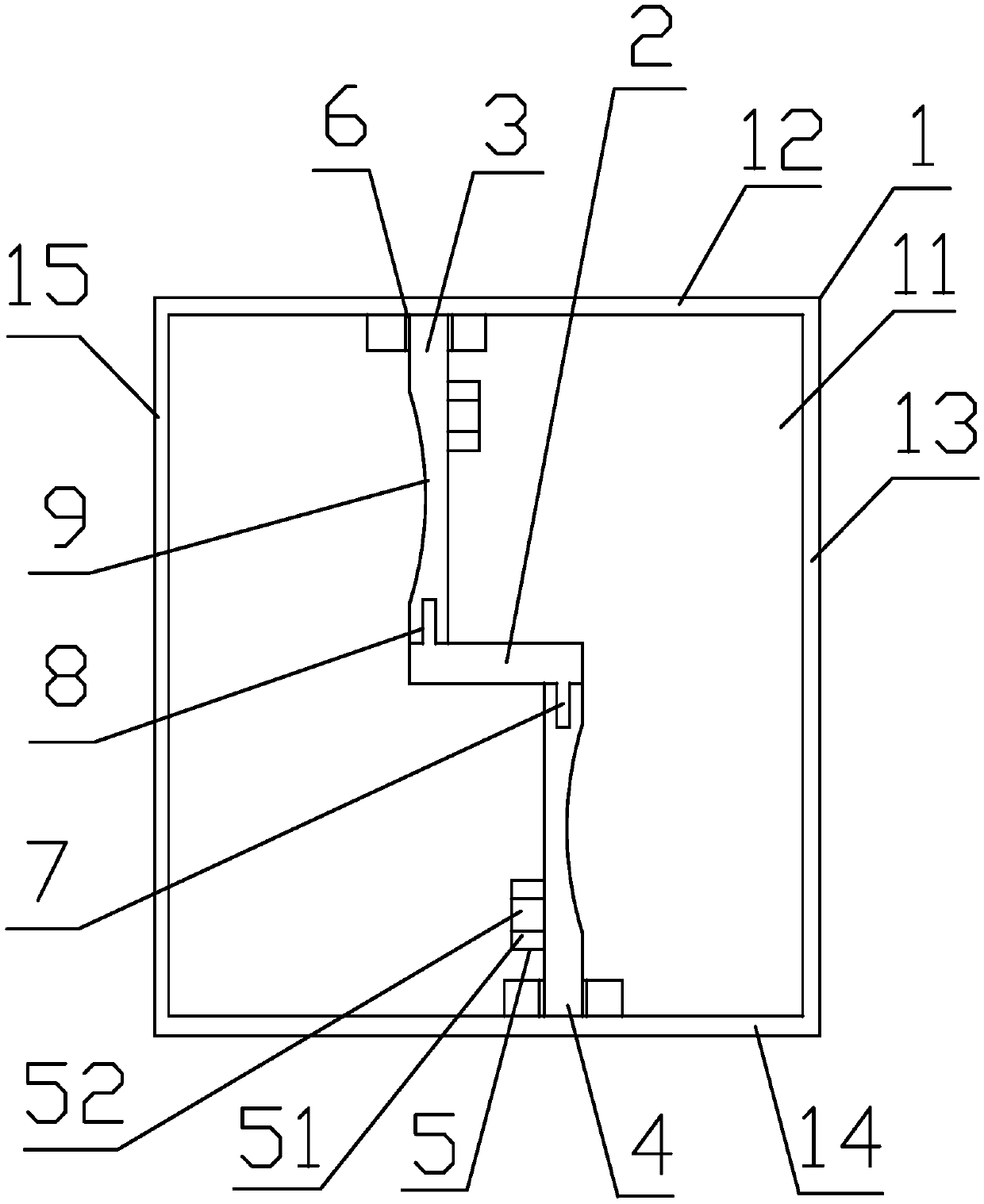

[0030] Such as figure 1 As shown, the present invention provides a multifunctional shoebox for placing high-heeled shoes, comprising a cuboid box body 1, said box body 1 comprising a bottom plate 11, and a first side plate 12 and a second side plate connected end to end in sequence 13. The third side plate 14 and the fourth side plate 15. The box body 1 is provided with a fixing plate 2 , a first partition 3 and a second partition 4 . The fixing board 2 is fixed on the bottom board 11 , and the fixing board 2 is parallel to the first side board 12 and the third side board 14 . The first partition 3 is arranged between one axial end of the fixed plate 2 and the first side plate 12, and the second partition 4 is arranged between the other axial end of the fixed plate 2 and the third side plate 14. A partition 3 and a second partition 4 are perpendicular to the fixing plate 2 and parallel to the second side board 13 and the fourth side board 15 . The cavity between the first d...

Embodiment 2

[0032] Further improvement on the basis of Embodiment 1, the inner wall of the first side plate 12 and the third side plate 14 is provided with a chute 6, the extension direction of the chute 6 is perpendicular to the bottom plate 11, and the axial direction of the fixed plate 2 Slide rails 7 protrude from the two ends to the two sides of the board respectively. Both the first partition 3 and the second partition 4 are provided with limiting sliding grooves 8 adapted to the slide rails 7 . The first partition plate 3 is slidably embedded and clamped between the chute 6 of the first side plate 12 and the slide rail 7 of the fixed plate 2, and the second partition plate 4 is slidably embedded and clamped between the chute 6 and the third side plate 14. Between the slide rails 7 of the fixed plate 2.

Embodiment 3

[0034] As a further improvement on the basis of Embodiment 2, the fixing member 5 includes a fixing block 51 and a fixing groove 52, and the fixing groove 52 is used for embedding the heel of the high-heeled shoe. The inner wall of the fixing groove 52 is provided with rubber foam, and the bottom of the fixing groove 52 is provided with an adsorption magnet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com