Disclosed are air conditioner electric cabinet heat dissipation structure and air conditioner

A technology of heat dissipation structure and electric control box, which is applied to the structural parts of electrical equipment, details of space heating and ventilation, and household heating, etc., can solve the problems of complicated piping arrangement, increased cost of the whole machine, and impact on heat dissipation efficiency. , to achieve the effect of reducing cost, simple structure and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

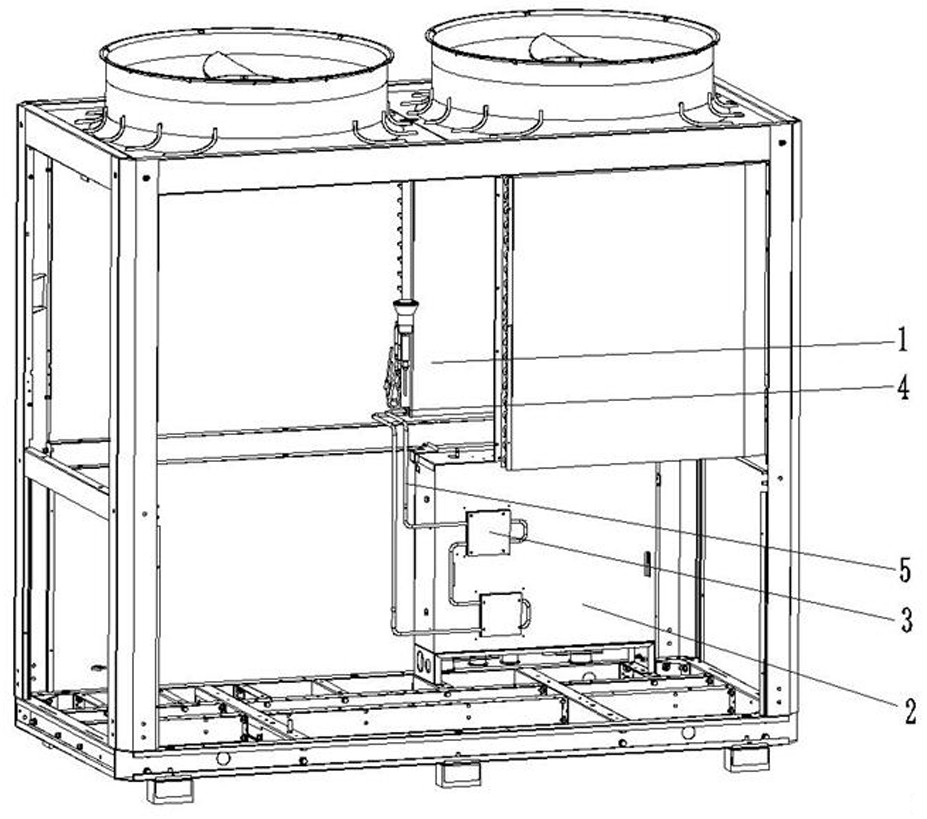

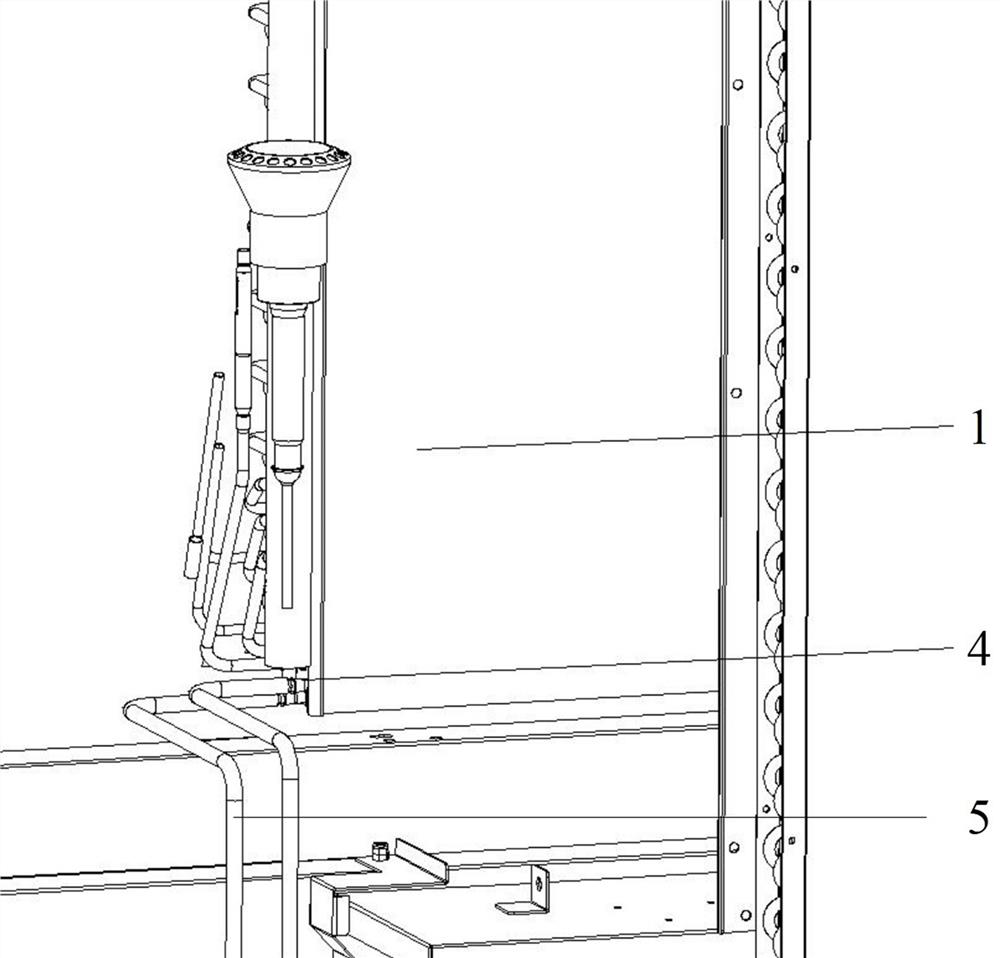

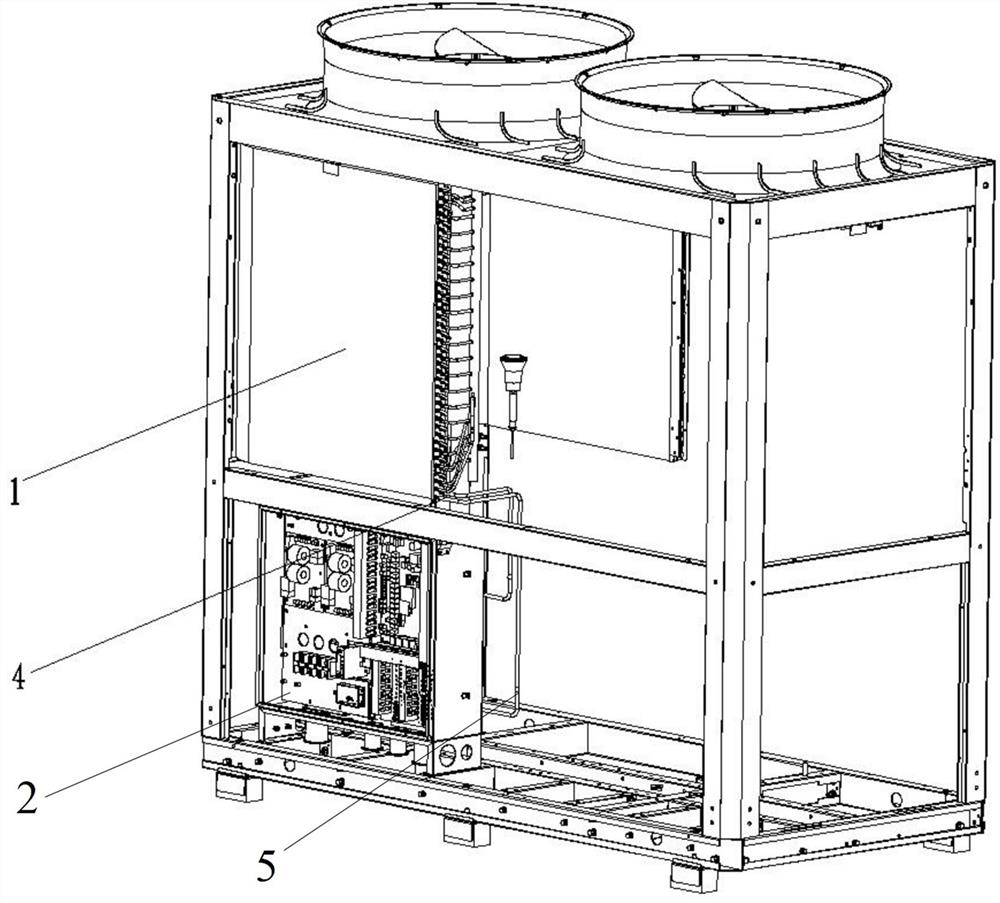

[0025] The following is attached Figure 1-6 And embodiment further illustrate the present invention.

[0026] The present invention provides a heat dissipation structure for an air conditioner electric control box, including a heat exchanger 1. As an embodiment, the heat exchanger 1 is an air-cooled finned heat exchanger, preferably a condenser, and its air-cooled fins are set In the air conditioning cooling duct.

[0027] Also comprise electric control box 2, on the shell of electric control box 2, preferably be provided with the radiator 3 of band closed cooling circuit on the back side of the shell of electric control box 2, this radiator 3 is aluminum radiator, also can It is a copper radiator 3; the radiato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com